Data standardization. Let’s be honest: to most people in construction, there are topics that sound far more intriguing, but don’t underestimate the power of structured data.

There is a growing expectation that systems automatically “talk” to each other and exchange data to make tedious tasks convenient. We’ve become used to this in our private lives. We expect different applications in our smart, connected homes to feed into a single platform, regardless of manufacturer.

In the construction context a similar pressure from end-users can be felt. Switching between applications for daily routines takes time and resources. The demand for a single source of truth and integration into existing systems like enterprise resource planning (ERPs) is growing. The key to value creation is no longer to provide an excellent standalone product. Success will be defined by organizations’ ability to offer products that seamlessly integrate into systems and allow customization on the end-user side.

But it’s not just a question of convenience. If we take a look at the fintech industry FinTechs we see that open systems and data sharing have been the major innovation drivers. This invites investors and start-ups to “plug in” and help solve complex business challenges, always with the customer experience and safety in mind.

We’re witnessing a massive shift away from the traditional product mindset towards what we call the Era of Ecosystems in construction.

Frontrunners are looking at the customer experience as a whole, instead of single products, when developing new offers. The element that can hold the experience together is data.

And we don’t need huge amounts of complex data. Relatively simple data sets can already provide plenty of useful insights – that is, if the data is structured. Let’s take a closer look.

Taking one step back while the industry is taking two big steps forward sounds counterintuitive at first – but it’s worth it. A simple example shows how important the right base is.

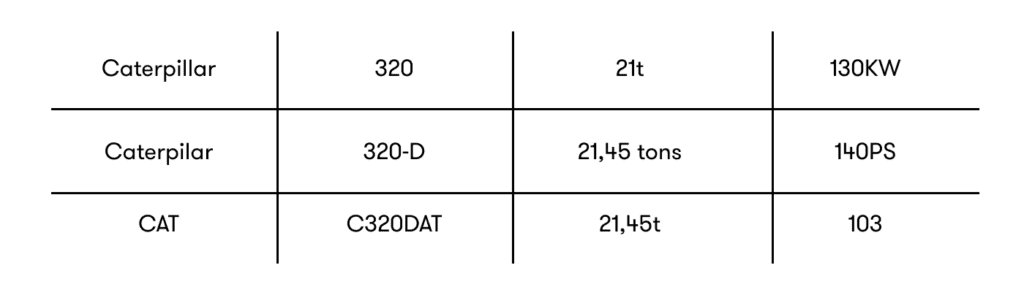

If you take a look at a data set to compare and evaluate whether the entries belong in the same category, a system will read the following:

While it is obvious to you that this is one and the same asset, your system classifies it as three different types. This can skew analysis and create errors. In computer science, this phenomenon is sometimes referred to as “garbage in – garbage out”, meaning that unclear input will result in inconclusive output.

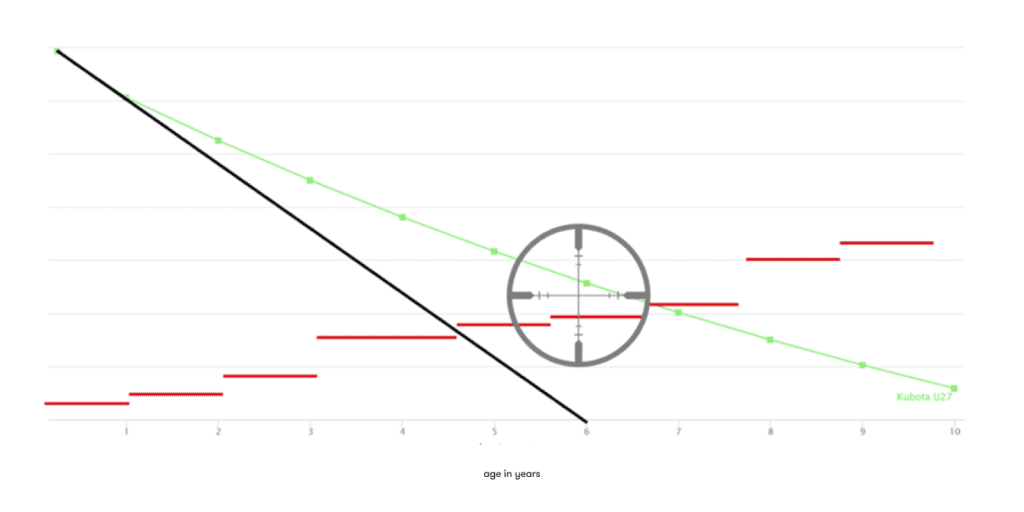

One use case to exemplify how (structured) machine data can be applied relates to total cost of ownership (TCO). Every asset has its linear depreciation (black curve), but the true condition and health of a machine depends on how it’s been used. Usage can “push and pull” the curve and if we collect machine data we can map out a dynamic residual value forecast (green curve). Adding cumulative costs of the machine, such as maintenance on top (red lines), we can determine an economical loss zone which then gives us an optimal time to sell.

The more (standardized) data sets from different machines we can feed into the model, the more accurate the predictions will become.

What does this mean to the customer experience? In this prototype, the process could run automatically in the background and send notifications about which machines are getting close to a critical area economically. We could then automatically determine optimal resell time. Decisions can be based on facts instead of gut feelings.

Selling assets at the right time has an obvious positive effect on a fleet owner’s bottom line, but there are wider implications to this. On the one hand, by making the best use of machines and assets before replacing them we can extend lifecycles and save valuable resources. On the other hand, if assets have been used more than expected it is a good opportunity to replace them with more modern and energy-efficient machines.

Standardization and sharing of data is by no means an easy challenge and it requires a lot of different stakeholders to collaborate, but there’s huge potential for those who dare.

With the Inside Eliminate Downtime Newsletter you receive the latest on the Eliminate Downtime movement and three curated articles on topics such as digital transformation, innovation and leadership on a regular basis in your inbox. Stay in the loop, sign up today.

Never miss an insight. We’ll email you when new articles are published on this topic.