Hugg & Hall had been early adopters of telematics from the late ’90s through the 2010s. After going through this experimental phase, they discovered that telematics solutions were too generic, and they needed to dismantle and potentially harm equipment to install telematics. They experienced reliability issues and broken promises when integrating telematics with their business systems.

With 6000 pieces of equipment and 40 trucks in his fleet, Rental Operations Manager Chris DeMoss oversees a diverse fleet. Having such a large fleet means that several different telematics systems were in place to create a complete fleet overview. The multiple systems created a disjointed system that didn’t work together. This was one of the keys to realizing that Hugg & Hall needed a system that wasn’t generic.

With multiple depot locations, Chris and his team regularly spent hours looking for equipment. This would add up to thousands of hours a year. With a telematics system in place, they could minimize the time spent looking for equipment. It would save both time and money.

Hugg & Hall had four immediate business objectives to succeed with when choosing a telematics provider:

“With such a large yard and many machines, you have to figure out how to make all those machines work together to form a cohesive unit.”

Chris DeMoss, Rental Operations Manager

In 2018, Chris reached out, and with the help of the solutions, engineering, technical support, and account teams, we came up with a solution to manage Hugg & Hall’s large fleet of equipment and trucks.

The prescription consisted of a mixture of telematics software solutions and hardware, which have continued to evolve over time into today’s flexible telematics system. These solutions enabled Hugg & Hall to adapt to different machine types and applications, whether that’s communicating to engines and controllers or for more basic applications. The technical support team is always there to provide integration and installation guidance as needed.

Chris also takes advantage of the OEM factory fit program, reducing the need for retrofit installations on new equipment. Some major OEM brands come factory supplied with telematics, allowing Hugg & Hall to centralize data into one platform.

Hugg & Hall use an ERP system to manage business operations, so an integration that works with the chosen telematics system was significant to Chris. Hugg & Hall did not want to get stuck in the middle, coordinating processes between the two providers. To solve this problem, the implementation team stepped in, enabling Hugg & Hall to stay hands-off. The API integration was successful in connecting data that flowed seamlessly from our telematics platform to Hugg & Hall’s ERP system.

Hugg and Hall’s most immediate impact experienced was through operational savings from switching from 60-day maintenance intervals to machine hour meter-driven events. With over 2000 electric scissor lifts in the fleet, Hugg & Hall estimated a savings of $500,000 in maintenance costs by changing maintenance processes from a set schedule to basing service and maintenance on machine data.

While Chris can minimize the amount of service and maintenance conducted on machines. The opposite can also be true. Sometimes equipment can be on a site and rack up 600-700 hours, knowing this means that they can also service the machine immediately, avoiding any unexpected breakdowns.

“Sometimes in 60 days, a busy yard truck in a distribution center could have 600-700 hours on them! Now we have captured these maintenance intervals at 250 hours and are saving engines.”

Chris DeMoss, Rental Operations Manager

Since the program launched, there have been three theft recoveries, including a skid steer, towable welder, and mini excavator. Theft recovery has eliminated the loss of customer productivity, business income, time, and insurance expense related to replacing the machines.

Chris notes that they have increased customer satisfaction by seizing an opportunity to share equipment data with their customers. Since all the telematics data was flowing into their ERP business system, they worked with their web developer to create a customer-facing portal on Hugg & Hall’s website, leveraging business information combined with rental data. Customers can now log in to use the Hugg & Hall portal to see a map of everything on rent. With full rental and utilization details, customers can use that data to make decisions to call equipment off rent for a pick-up.

Hugg & Hall will continue to equip machines with telematics. Connecting a higher percentage of the fleet will enable Chris to get more and more value out of machine data and improve internal processes and the customer experience.

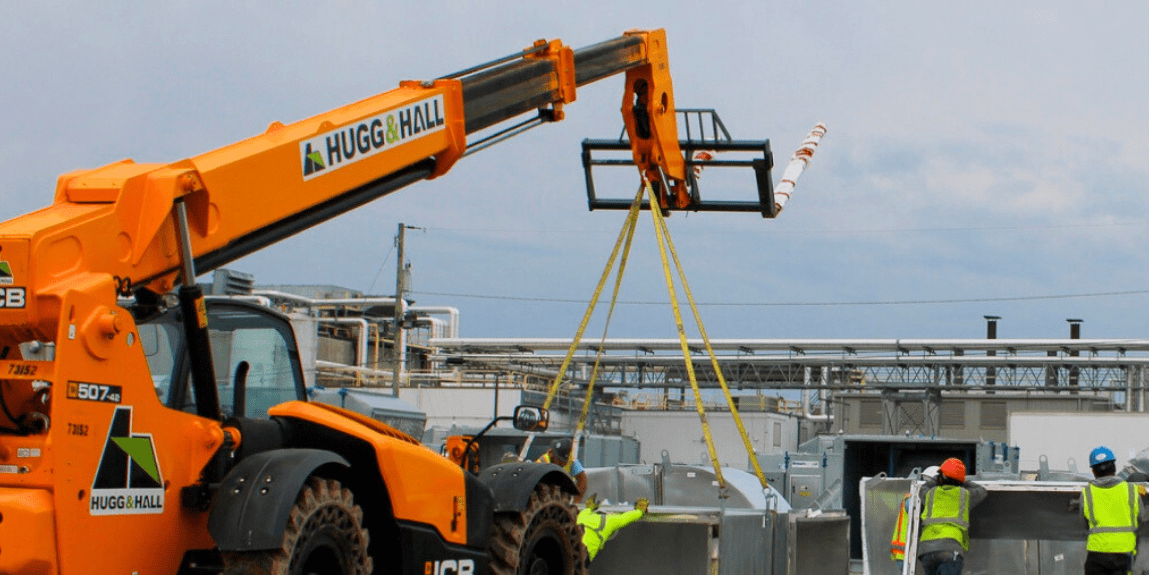

Formed in Arkansas in 1956, Hugg & Hall provides equipment sales, rental, and parts for materials and personal handling products in the industrial and construction markets. With 17 locations serving Arkansas, Oklahoma, Louisiana, Missouri & Texas, the company focuses on delivering exceptional customer experiences while growing and evolving operations.

Founded: 1956

Size: 265+ employees