In the rush to talk about smart jobsites, digital twins, and autonomous machines, it’s easy to overlook the fundamentals — the building blocks of digitized construction. One of those blocks is construction telematics.

While it’s hardly a new technology, its role in construction has never been more vital or more varied.

From OEMs to rental companies to contractors, construction telematics continues to reshape how we manage machines, sites, and resources. And while the industry buzz often revolves around what’s next, it’s worth stepping back and appreciating what telematics already delivers and what it’s quietly setting the stage for.

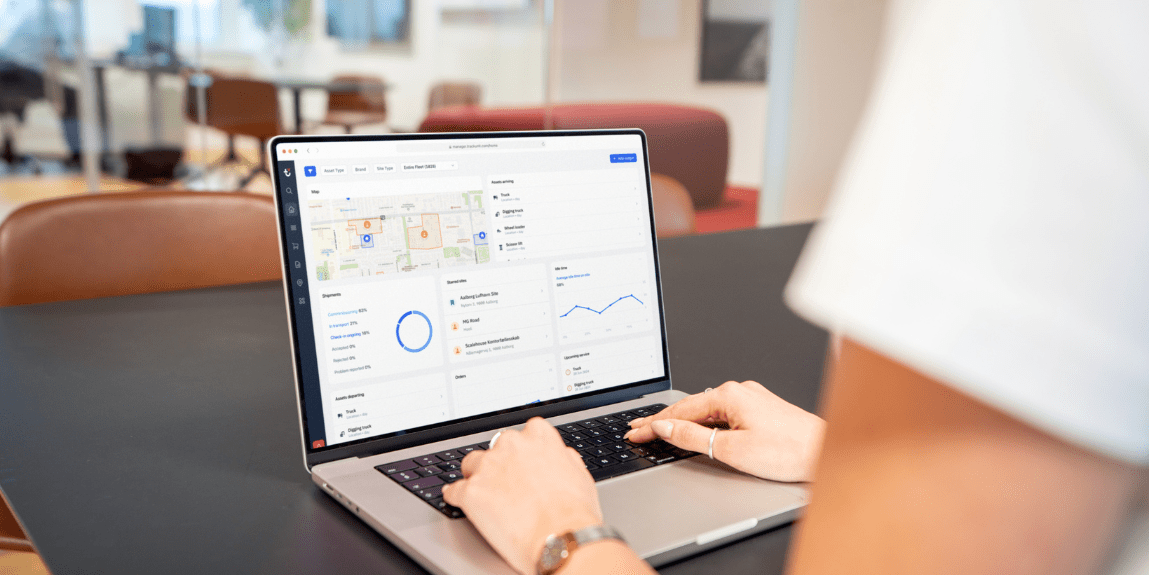

At its core, construction telematics is about data. Specifically, the real-time transmission of machine data — location, usage, fuel consumption, engine hours, and more — over cellular or satellite networks. This seemingly simple data stream unlocks a range of capabilities that reduce cost, improve safety, and increase uptime.

Take fuel consumption. A site manager tracking idle time across a fleet of excavators can quickly spot inefficiencies, address operator behavior, and cut unnecessary fuel use. Multiply that by hundreds of machines across a contractor’s portfolio, and the savings become significant, not just economically, but environmentally.

Then there’s maintenance. Predictive servicing has become the norm thanks to engine-hour tracking and fault code alerts. Engine-hour based servicing is more accurate than calendar-based servicing given the latter is premised on an estimated number of hours in a given time period. That should enable better scheduled servicing and significant potential savings.

Construction telematics also allows both OEMs and rental providers to preempt breakdowns, keep machines running longer, and reduce unscheduled downtime. For equipment rental businesses, that’s a game changer: machines that break down on customer sites don’t just cost in repair, they cost in customer satisfaction and repeat business.

And let’s not forget theft prevention. Telematics-enabled geofencing and remote immobilization features have helped clamp down on one of the construction sector’s long-standing pain points.

Contractors working in remote or high-risk areas can rest easier knowing that their machines are tracked, secure, and they can be notified proactively if a machine moves out of a specific location or works outside a given time period.

The beauty of construction telematics is that it meets each part of the value chain in different ways.

OEMs, for instance, use construction telematics to stay connected to the lifecycle of their machines. By analyzing real-world usage data, they can refine future designs, tailor servicing packages, and offer better aftersales support. More importantly, this data lets OEMs deepen relationships with customers, especially as ‘machine-as-a-service’ models start to gain traction.

“While the industry buzz often revolves around what’s next, it’s worth stepping back and appreciating what telematics already delivers and what it’s quietly setting the stage for.”

Rental companies lean heavily on construction telematics for logistics and efficiency. With thousands of machines moving between customers and depots, having a bird’s-eye view of fleet health and availability is crucial. Telematics informs everything from billing (based on accurate usage data) to redeployment (knowing where idle assets are). It’s also essential for right-sizing fleets and reducing overcapacity, a key consideration in a margin-sensitive business.

Contractors, meanwhile, value visibility. Whether managing a mixed fleet across a megaproject or tracking smaller equipment across multiple sites, construction telematics brings a sense of control. Knowing where everything is, how it’s performing, and who’s operating it reduces friction and improves productivity. Add in alerts for overdue maintenance or out-of-hours usage, and the jobsite becomes more predictable, and less risky.

While basic telematics continues to add daily value, the real opportunity lies in what comes next. As machines become more connected and software platforms more sophisticated, construction telematics data is evolving into something more powerful: operational intelligence.

Access management is one example. By linking telematics to digital ID systems, site managers can control who operates what and when. This ensures compliance with safety regulations and reduces the risk of inexperienced users damaging high-value, heavy equipment as well as keeping jobsites intact. It’s a step toward not just tracking machines, but governing them.

“As machines become more connected and software platforms more sophisticated, telematics data is evolving into something more powerful: operational intelligence.”

Emissions monitoring is another fast-developing use case. As construction faces increasing pressure to decarbonize, construction telematics is enabling real-time tracking of fleet-wide emissions. OEMs can use this to report on compliance with EU Stage V or Tier 4 regulations. Contractors and large infrastructure projects can use it to demonstrate sustainability KPIs to clients and regulators.

Utilization analytics, meanwhile, offer a new layer of insight. Rental companies and contractors alike are using telematics data to understand whether equipment is earning its keep or just taking up space. Underused machines can be reallocated, sold, or decommissioned, freeing up capital and improving ROI. In large fleets, this data-led approach can redefine procurement and deployment strategies.

What makes this all work isn’t just the machine. It’s the ecosystem. The combination of connected hardware, cloud-based platforms, and open APIs is what allows telematics to integrate into broader operational workflows. And this integration is where real productivity gains lie.

For example, connecting construction telematics with project planning tools can allow contractors to forecast machine needs more accurately. Integrating with finance systems ensures accurate invoicing based on actual use. And linking with safety platforms supports incident investigations by providing a timeline of machine activity.

This kind of ecosystem thinking is becoming the norm, especially among large construction players and forward-looking OEMs. It’s about moving beyond point solutions and toward connected systems — ones that reflect the complexity and interdependence of the modern jobsite.

The future of construction telematics isn’t just about more data, it’s about better decisions. As machine learning and AI are layered onto telematics platforms, the goal is to move from reactive to proactive and, eventually, predictive. Imagine a rental company that can anticipate demand before the phone rings. Or a contractor whose fleet configures itself based on the type of work planned for the week.

“A site manager tracking idle time across a fleet of excavators can quickly spot inefficiencies, address operator behavior, and cut unnecessary fuel use.”

But we’re not there yet. For many in construction, the real gains are still being realized through the basics. That doesn’t mean uprooting everything and starting again. It can simply mean a fine-tune of the systems and technology you already have in place to keep machines visible, efficient, and secure. And that’s the message that often gets lost in the noise.

Telematics isn’t a nice-to-have. It’s a cornerstone of modern construction. Whether you’re building the machines, renting them out, or putting them to work, the value is already there, and it’s only going to grow.

Foundations is our new series focusing on the nitty gritty of construction technology and showing how to make it work for your business day-to-day. Want to find out more? Visit Trackunit today and make sure you’re fully connected.