In construction, the margin between success and failure often comes down to one word. Delay. Whether it’s equipment idle, maintenance surprises, materials arriving out of sync or poor coordination, delays kill budgets, reputations and future work.

But across the industry today, there is growing, compelling proof that connectivity and digital-tech aren’t optional. They’re the difference-maker.

Multiple specialist reports point to the same truth: improving visibility, linking people and machines, and turning data into action unlock measurable gains. For example, the Royal Institution of Chartered Surveyors found that only 9 % of contractors globally expected productivity to increase in the following 12 months in its 2023 survey, under-lining that the industry is currently under-performing in productivity.

Indeed, McKinsey’s Fabian Metzeler said as much in the media pointing to a sub-1% productivity rise in construction over the past two decades, massively under-performing peer industries.

Yet, while that under-performance has allowed a certain complacency to continue in construction, the shift toward digitalising processes and tech integration has run parallel to become a high-impact lever for productivity, the RICS report shows.

In plain language: if you don’t bring your machines, people, and workflows into a connected environment, you’ll be competing from behind.

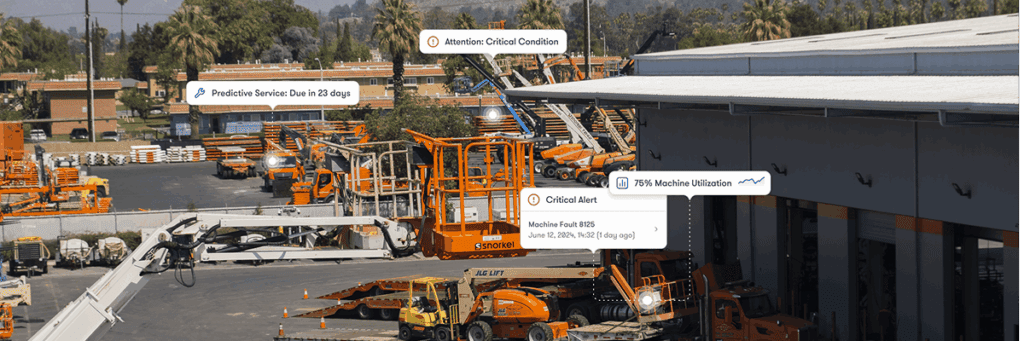

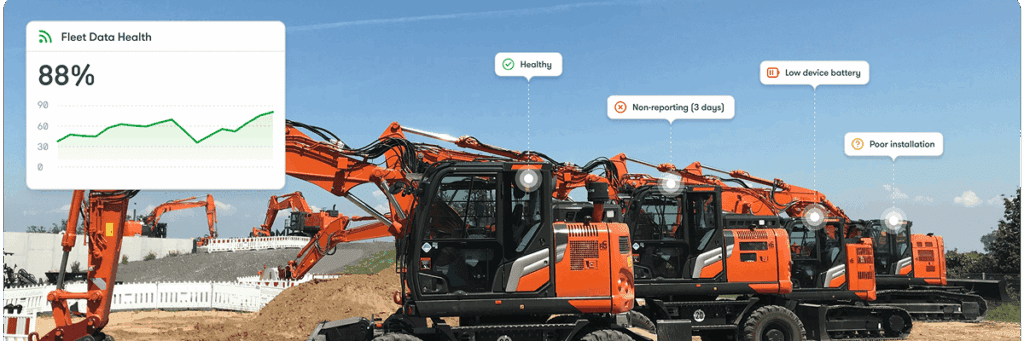

When contractors track the right metrics, the return on investment becomes tangible. A recent guide on construction equipment ROI emphasises that top firms now monitor daily metrics like utilisation rate, idle time percentage and cost per productive hour.

When contractors track the right metrics, the return on investment becomes tangible.

Other sources show that manufacturers of heavy equipment and contractors using connected and semi‐autonomous machines report productivity gains of 20-30 % or more.

Further, the Procore ‘ROI of Construction Technology’ report found dozens of firms achieving improved predictability, fewer overruns and more profit by connecting data, people and processes.

Trackunit‘s ’Sites’ solution page meanwhile, sshows contractors using the platform were able to reduce idle time by 20-30 % across jobsites while its Equipment Utilization use-case reports a saving of US$146K through a 20 % reduction in idle time over five years across a fleet.

Put simply: if you invest in connectivity and tech, you’re likely to recover that investment not just in cost-savings, but in earlier project delivery, improved capacity and fewer surprises.

Let’s flip that around. If you stay in a disconnected state — machines isolated, data fragmented, decisions made on partial visibility — you’re not just missing upside. You’re heading toward loss.

In short, the risk moves from “we don’t win as much as we could”, to “we lose ground, margin and opportunity to operators who do”.

If you stay in a disconnected state, you’re not just missing upside. You’re heading toward loss.

Here are the key outcomes you should expect if you deploy connectivity and tech intelligently:

If you’re ready to act, here’s a practical roadmap:

Budget overruns, schedule slippages, idle machines, and frustrated crews are not inevitable. They are avoidable, and there is credible evidence across the construction sector that connectivity and digital tech can change the game.

You’re not investing in gadgets. You’re investing in control, predictability and margin.

You’re not investing in gadgets. You’re investing in control, predictability and margin. And in this industry, being connected isn’t just a nicer option, it’s quickly becoming the baseline for competitiveness.

The proof is there, the tech is available and the ROI is waiting. The only question is whether you claim it. Because someone else will.