DiTec are on a continuous growth trajectory. They have expanded the business by fleet size and the diversity of their offer. Always looking to expand, they have recently extended their company premises. With a new service hall and more space for machines, DiTec are looking to advance their customer service.

To further develop the business, they implemented their ERP solution. They have been able to turn tedious, manual processes into a paperless, automated journey. DiTec also identified the need to merge data points from several different manufacturers into one platform. They wanted a solution that could support them on this journey.

So, even though DiTec have experience with implementing and developing digital solutions they needed a solution that would give them the ability to:

“We did not want to waste our time on a premature solution. With Trackunit, we found a reliable system that helps us achieve lasting success.”

Frank Schmenn, Executive Partner

DiTec tested the flow of machine data with their ERP system, and the results were convincing. Not only did they see how this telematics solution would solve their current pains, but it opened up new opportunities as well.

Today DiTec can track machine usage remotely and react accordingly. It has improved their billing process but has also helped them provide better customer service. Errors are quickly detected and can be fixed on-site, significantly reducing downtime of machines. In some cases, identifying potential risks before they become a problem is also possible, eliminating machine downtime.

Together with Trackunit, DiTec have been able to meet their objectives in a timely and efficient manner and, consequently, improved customer satisfaction and retention. With the system in place, they are prepared to respond to fluctuating customer needs and demands for real-time information

“The reaction from customers when we fix a problem before they even notice there was an issue is priceless. It just improves our service quality on a whole new level.”

Frank Schmenn, Executive Partner

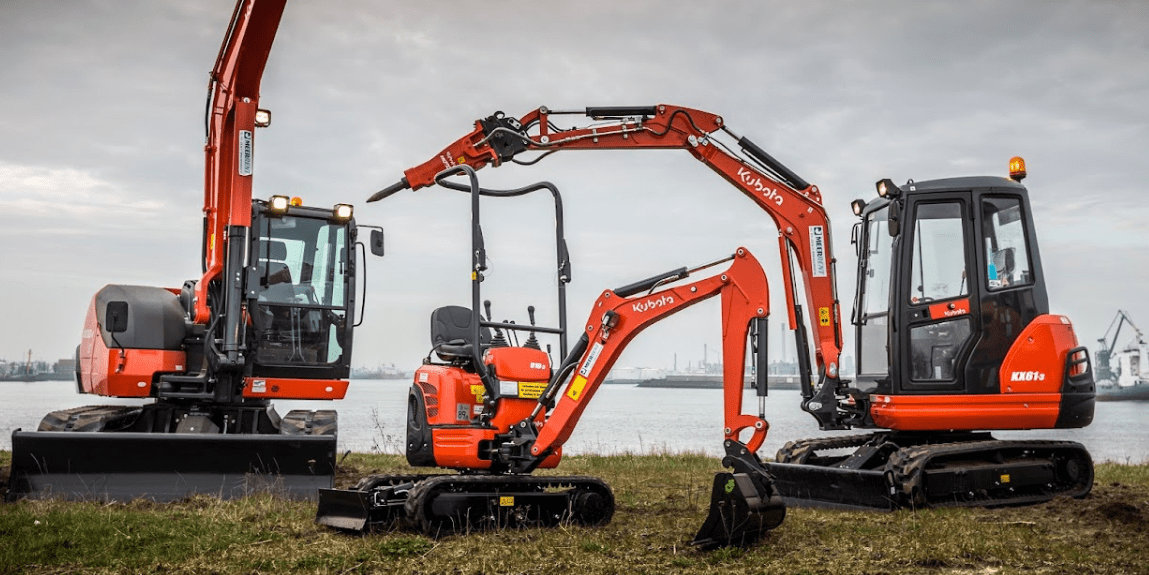

DiTec Baumaschinen rent, sell and maintain construction equipment. Based in Germany, they offer a diverse product portfolio. They offer their customers everything from consumables and tools to heavy construction machinery.

Founded: 1993

Size: 50+ employees

Never miss an insight. We’ll email you when new articles are published on this topic.