Ask any contractor what keeps them up at night, and chances are it’s not just winning bids, it’s delivering them. Every lost hour on a jobsite is effectively money down the drain and the evidence is legion. This report alone shows annual losses of USD 177 billion in the US and that ripples across schedules, budgets, and reputations.

Weather, supply chain hiccups, labor shortages, and unforeseen maintenance are all familiar enemies. But in an industry where margins are often razor-thin, downtime is the silent killer.

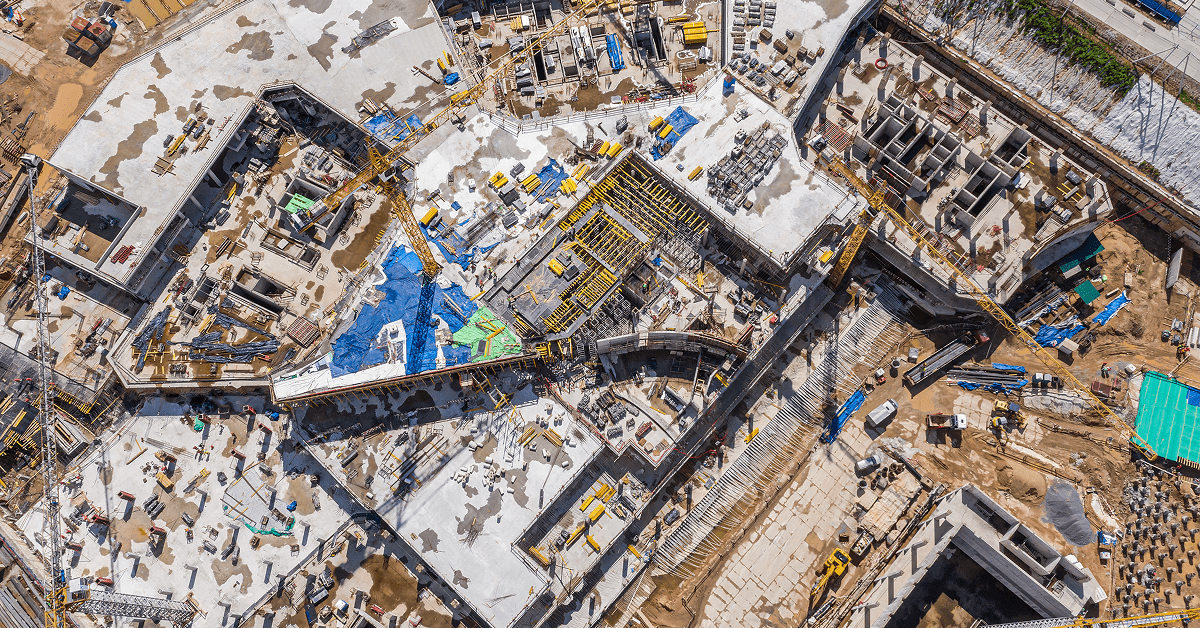

What’s changed over the past few years is that the industry is no longer resigned to this. Connectivity has become a tool for control offering visibility, coordination, and data-driven decision-making that was once little more than a pipe dream. While some firms are still relying on instinct and radio calls, others are already building connected ecosystems where every asset, operator, and process is part of a single, real-time picture.

The result? Projects that stay on schedule, equipment that earns its keep, and teams that work smarter, not harder.

Ten years ago, the idea of connected equipment might have sounded like a luxury, an experiment for OEMs or tech-forward contractors. Today, it’s high stakes. Contractors that haven’t embraced connected workflows are beginning to feel the pressure, not just from clients but from competitors who’ve cut days, sometimes even weeks, off their delivery schedules.

Connected construction doesn’t mean adding gadgets for the sake of it. It means integrating machines, people, and data so that every resource is optimized. It’s the difference between reacting to a problem and anticipating it. Between calling a mechanic after a breakdown and preventing the breakdown altogether.

“Contractors that haven’t embraced connected workflows are beginning to feel the pressure, not just from clients but from competitors who’ve cut days, sometimes even weeks, off their delivery schedules.”

In short, connectivity shifts the balance of control. For the first time, contractors can see their operations as they actually are, rather than as they assume them to be.

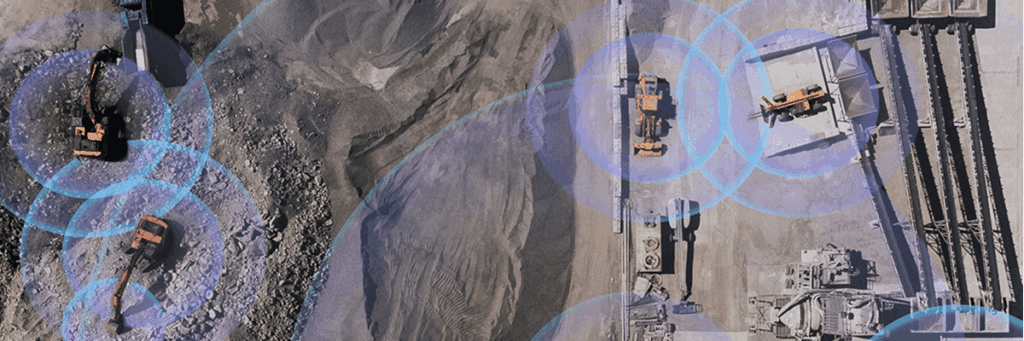

Consider equipment utilization. In traditional setups, machines spend up to 30–40% of their working life idle. That’s capital sitting still, draining value. Connected fleets, on the other hand, allow contractors to monitor usage patterns, fuel burn, and idle time in real time. When one site is short on assets and another has surplus, redeployment can happen within hours, not weeks.

The same principle applies to subcontractors, deliveries, and even weather-sensitive operations. With connected platforms linking data from multiple sources, project managers can spot risks before they materialize. Instead of learning about delays after they’ve happened, they can reallocate resources on the fly, keeping progress uninterrupted.

In the past, this kind of insight required instinct. Now, it’s a matter of intelligence.

Connectivity doesn’t just improve visibility, it institutionalizes collaboration. Many delays occur not because people are unproductive, but because information moves too slowly between them. A disconnected jobsite is full of blind spots: crews waiting for instructions, materials arriving at the wrong time, equipment that no one realized was down for maintenance.

“Connectivity doesn’t just improve visibility, it institutionalizes collaboration. Many delays occur not because people are unproductive, but because information moves too slowly between them.”

Digitally connected contractors are changing that dynamic. They use shared, real-time dashboards where every stakeholder, from site managers to office planners, sees the same version of the truth. Tasks are assigned, progress is tracked, and communication happens in context. Instead of managing chaos, project leaders can orchestrate performance.

The knock-on effect is cultural, not just operational. When teams have clarity, accountability follows naturally. The “us vs. them” mindset that often divides field and office starts to disappear.

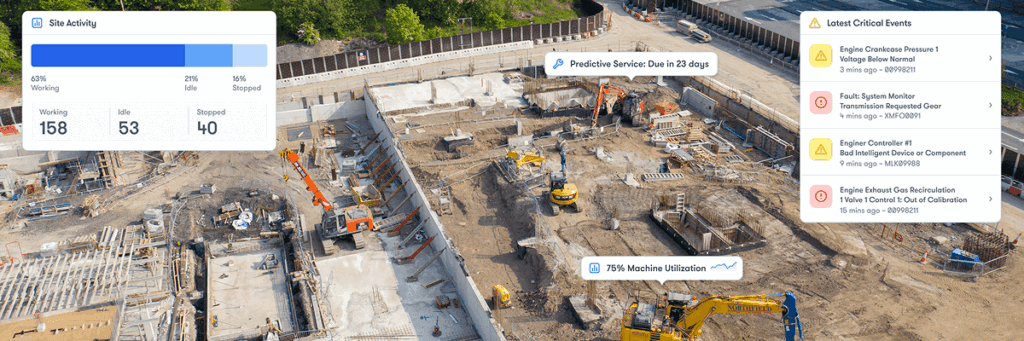

Few things cause as much frustration as unexpected machine failure. But connectivity turns maintenance from a reactive chore into the potential for a predictive science. By analyzing data from connected machines — hours of operation, temperature, load, vibration — contractors can anticipate service needs before breakdowns occur.

Predictive maintenance is one of those quiet revolutions that doesn’t make headlines but will save fortunes. It’s not just about preventing costly repairs; it’s about keeping schedules intact. Every machine that stays running keeps crews productive and timelines on track.

Over time, the data gathered from connected assets also guides smarter procurement as contractors can assess with ever-increasing certainty which brands, models, and configurations deliver the best ROI.

This shift from firefighting to foresight is one of the defining characteristics of the new era of construction. The move toward connectivity isn’t simply about technology; it’s about intelligence.

Every connected operation generates data, tons of it. The contractors who learn to interpret and act on that data are the ones pulling ahead. Data reveals inefficiencies invisible to the naked eye: excessive idling, overlapping rentals, bottlenecks in site access, underperforming operators, or even patterns in project delays.

With analytics, there will no longer be mysteries, just opportunities. The best contractors are treating their operational data the same way financial institutions treat their balance sheets — as strategic assets. As connectivity deepens, we’ll see the emergence of truly data-driven contractors making decisions not based on gut feeling, but on hard evidence. The question isn’t whether this transformation will happen, but who will still be standing when it’s complete.

Despite all the talk of digital tools, the future of construction is still human. Connectivity doesn’t replace people; it empowers them. For site supervisors, it means less firefighting and more focus on coordination. For operators, it means fewer delays and safer conditions. For executives, it means the confidence to promise delivery and the ability to keep that promise.

Adoption, however, requires mindset change. Technology only works when people believe in it. The most successful contractors invest as much in culture as they do in IoT and software, training teams, aligning incentives, and building trust around data transparency.

Every contractor knows that change carries risk. Integrating new systems can be disruptive, especially in an environment where deadlines and margins leave little room for experimentation. Yet the bigger risk is inertia.

Competitors who’ve already embraced connectivity are quietly gaining an advantage: faster project delivery, reduced fuel costs, better safety metrics, and happier clients. In tender negotiations, those numbers speak louder than promises. In an industry built on reputation, the perception of being behind the curve can be as damaging as the reality. The fear of missing out isn’t just about missing the latest tech trend, it’s about missing the future of how work gets done.

“Every contractor knows that change carries risk. Integrating new systems can be disruptive, especially in an environment where deadlines and margins leave little room for experimentation. Yet the bigger risk is inertia.”

Construction has always been about the coordination of people, machines, and time. Connectivity simply extends that coordination to the digital realm. It’s not about replacing hard hats with headsets — it’s about ensuring every piece of the operation works in harmony.

The tipping point has already arrived. The contractors delivering projects on time, within budget, and with fewer headaches aren’t the ones who’ve been luckier. They’re the ones who’ve been smarter about adopting technology. If you’re still operating in isolation — without connected equipment, shared data, or real-time visibility — you’re not just behind schedule. You’re behind the industry.

The construction landscape is evolving fast. Those who wait for the perfect moment to go digital will find that moment never comes, and by the time it feels safe, the competition will already be miles ahead. Connectivity isn’t just a tool for better construction; it’s becoming the foundation of competitiveness itself.

The best contractors are proving that delays don’t have to be inevitable, and that technology isn’t the future of the industry anymore. It’s the here, the now and the necessary.