There’s nothing that gets construction professionals quite so exercised as health and safety. Or for that matter, quite so unified. While there is resistance in many areas of the industry towards data sharing, this is one where we don’t skimp. If we can make our workers safer, the consensus is there to enable that.

And the efficient, effective and above all, safe utilization of people is an absolute and essential element of eliminating downtime. Without due consideration for its people, the industry-wide push for an end to downtime and being more useful to the world becomes an empty pledge.

Nevertheless, construction is still blighted by accidents that frequently result in fatalities. And a quick look at the figures collected by the International Powered Access Federation shows that aerial work platforms are one of the most dangerous places to work in the industry.

Without due consideration for its people, the industry-wide push for an end to downtime and being more useful to the world becomes an empty pledge.

There were 109 deaths from aerial platforms in 2021, the non-profit organization said in its annual accident report, down from 126 in 2020. IPAF is right to welcome the direction of the trend, but it is also right to acknowledge that those reported fatalities might only be the tip of the iceberg and the real figure could be much higher. While IPAF does sterling work in this area and Trackunit has collaborated closely with it for more than a decade to foster better access management and practice including helping IPAF deliver its excellent ePAL app, there’s a lot of work still to do.

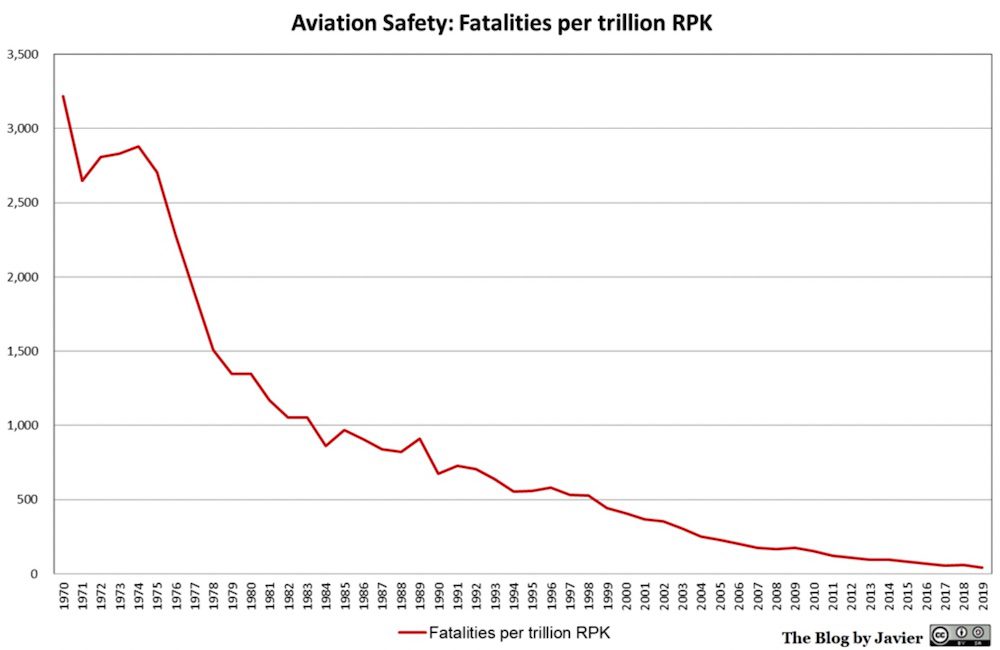

The experience of the aviation sector illustrates why. In the 1970s, there were 24,512 aeroplane passenger fatalities, according to wikipedia. In the current decade, the industry is on course for 2,674 fatalities, a little over 10% of that 1970s total. A glance at the following graph in revenue passenger kilometer terms (a more accurate measure given the growth of air travel since the 1970s) depicts the safety improvements perfectly.

That’s backed up by International Air Transport Association figures that show there was one accident for every 0.99 million flights in 2021.

This is no coincidence. Aviation has created an incredibly strong safety culture where pilots can log errors or ‘near misses’ without reprisal. With strong international bodies in place like IATA, watchdogs with teeth such as the US’s National Transportation Safety Board, regular and consistent training and finally, a check-listing procedure that is non-negotiable and unequivocal, the blocks are solid and integrated.

While some of these basic principles have also infiltrated the construction industry, not all have and where they have, it has tended to be unilateral and somewhat random be that at company, national or international level. The systematic implementation of such principles is exactly where construction should be aiming to go.

Aviation has created an incredibly strong safety culture where pilots can log errors or ‘near misses’ without reprisal.

There are a few obvious takeaways here. The importance of standardization and the gradual implementation of the Safety Management System in the airline industry as the benchmark for safety has helped accidents trend down. Secondly, that willingness to share root causes and learn has been instrumental in building the culture and the system.

Thirdly, aviation has quite clearly and unequivocally demonstrated a zero tolerance policy on safety. It’s something we in construction can certainly learn from as we sometimes waver between commercial imperatives and the absolute prioritization of safety.

Finally, and in the context of this argument key, airlines have also been able to utilize black-box data to learn why tragedies occur, take action and create an even safer environment for air travel than before.

So far so good you might say but without our own black box, this might all seem somewhat academic. Except, like aviation, we do have our own black box. The IoT devices fitted on aerial work platforms may not have the sophistication of an aeroplane’s all-knowing monitor, but it is at the heart of a huge amount of data every time a boom lift ascends into the sky and every time an operator moves the joystick this way or that.

It seems obvious but we may have missed the answer because access control has evolved from its original purpose of checking who’s going in and out — swiping literally — to become a conduit for mass data. And that data today vastly dwarves what the first PAL card (the forerunner of today’s ePAL app) developed by IPAF in the 1990s would have delivered.

It’s not all gloom. IPAF already has many of the bricks in place and the ePAL app is the glue that can bind those bricks together. But what is yet to happen is a systematic integration of those bricks as part a focus on making that data work directly towards safety and, most importantly, benchmarking.

We know about this data as we’re responsible for connecting circa 1.4 million assets on job sites and that’s just us. Others in the industry are doing the same too. That gives the industry a wealth of data that might, like a black box, help us understand what happened when a tragedy does occur. If we can all pool our data with due deference to GDPR concerns — that’s us, our peers, the OEMs and the aerial work platform companies — we can work on creating a standardized system like aviation.

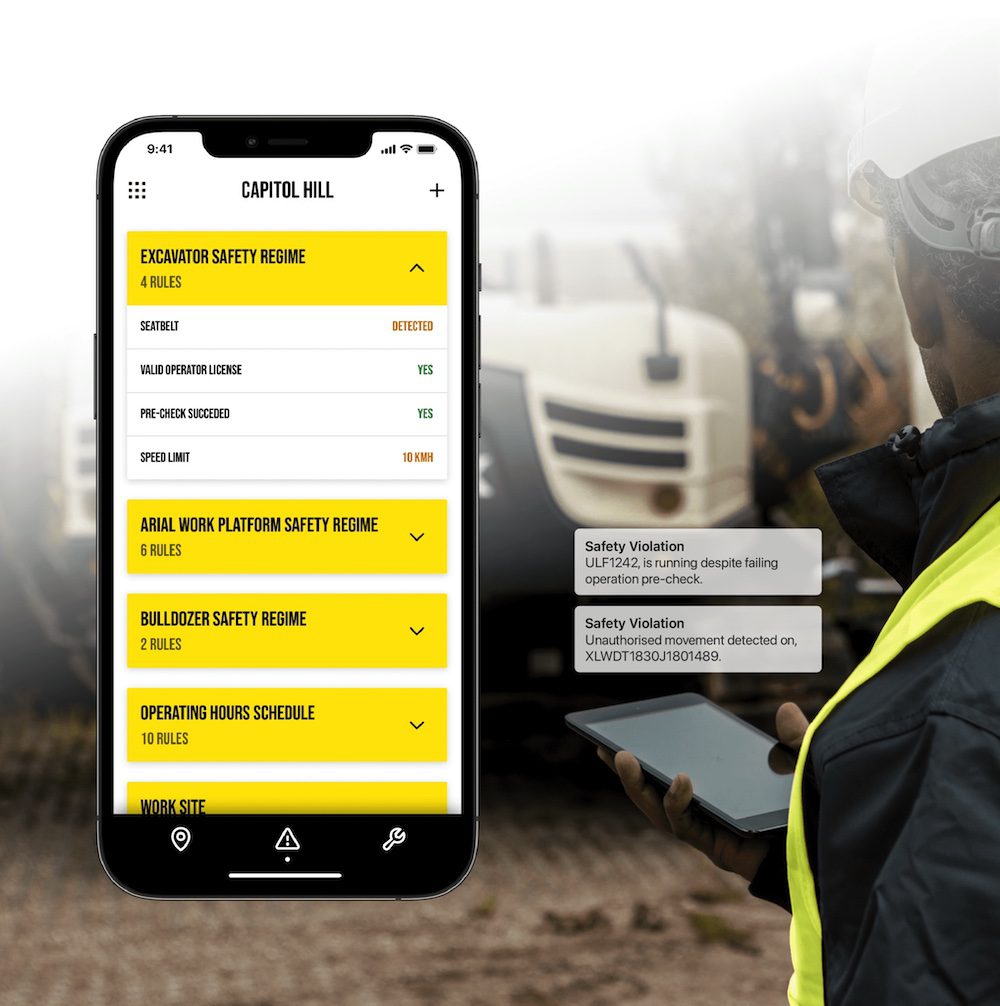

That would in turn enable a check-listing procedure as the prototype below shows that might help us make sure platforms don’t operate, for example, in hazardous weather.

Sharing our collective data is the key as it will help us emulate the critical role SMS has played in driving safety standards in the airline industry. Maybe, like aviation, we could simulate disaster scenarios for workers so that they might, at least theoretically, be armed with some basic understanding of what could happen on a platform in the event of something going wrong.

It would enable education and training of aerial work platform operators to a higher level than currently exists taking some if not all of the risk out of this essential yet dangerous job while instilling a dynamic towards ever higher standards if and when further incidents occur.

That would mean owners control access based on the level of certification creating a virtuous circle of training and development that works for owner, operator and safety-standards policymakers at national or international level in an integrated ecosystem where health and safety is the fundamental premise.

The net result should of course be a lower incidence of accidents and fatalities as the standard becomes practice and is subject to constant amendment and steady improvement.

…we could simulate disaster scenarios for workers so that they might, at least theoretically, be armed with some basic understanding of what could happen on a platform in the event of something going wrong.

We see IPAF as the natural home for this given the ePAL app has become the home of operators since 2020 and has furthered that process with the introduction of Keystone in the last couple of years.

We also anticipate legislative force helping to drive this perhaps building on the excellent examples in the UK and Italy. The latter, for example, offers tax incentives on construction safety to help imbed a culture that is more risk averse.

We’re more than willing to facilitate that development and make our data available to the industry with our peers across construction to create such a data architecture. It requires a bit of a reset and a willingness to cooperate but it would really set the bar and, when operators change company as they inevitably do in a hot market, a set of uniform rules would drive on-site behavior and foster safety.

So there we have it. That’s the potential template. The blueprint. The possible way forward. If it saves lives, then it has to be worth the effort.

The author will be expanding on the topic of access control and how we can unleash its potential at Europlatform 2022, which takes place in Rome on September 15.