In construction, the aftermarket is quietly redrawing the competitive landscape. Some OEMs are flourishing, turning connectivity and data into recurring profit and customer loyalty. Others are being left behind, trapped in old transactional models that no longer meet the expectations of digital-first customers.

For decades, OEMs relied on new machine sales to drive growth. But as margins have tightened and cycles have become more unpredictable, the aftermarket has emerged as the real engine of profitability. Every machine already in the field represents a long-term revenue stream through parts, upgrades, maintenance and services.

According to a recent report by Boston Consulting Group (BCG), for industrial-machinery OEMs aftermarket services now often carry gross margins twice those of new equipment which themselves typically earn circa 15-25%.

And in an article in Forbes, Deloitte says: “The average operating margin from aftermarket services globally is two to three times higher than the operating margin from new equipment sales.”

The challenge is that not every OEM knows how to tap into it.

Those that understand the new dynamics are building intelligent, connected ecosystems around their machines. They’re using data to anticipate customer needs, digital tools to simplify service, and technology to turn one-time buyers into lifelong partners.

The divide is becoming clear: OEMs that can connect and predict are growing. Those that can’t are competing on price, and they’re losing.

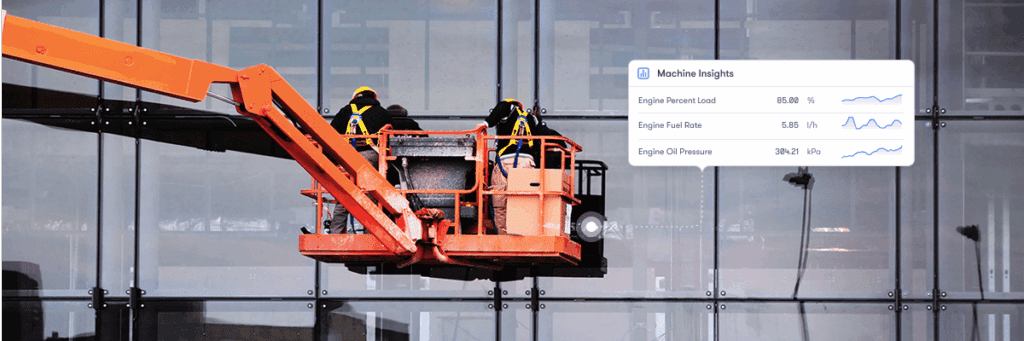

That connectivity is the accelerator is a no-brainer. With telematics and IoT sensors feeding a constant stream of machine data, OEMs can finally see what’s happening across their fleets in real time. They can identify patterns in usage, spot early signs of wear, and prevent failures before they happen.

For example, research into the OEM telematics market (for construction equipment) shows the installed base of OEM-provided telematics systems reached about 6.8 million units in 2023, and is forecast to grow to about 12.1 million units by 2028 with a CAGR of circa 12%+ for major OEMs.

“That connectivity is the accelerator is a no-brainer. With telematics and IoT sensors feeding a constant stream of machine data, OEMs can finally see what’s happening across their fleets in real time.”

This illustrates the scale of connectivity infrastructure being deployed.

Instead of waiting for a breakdown, the OEM becomes proactive, contacting the customer first, scheduling maintenance, or shipping the right part before downtime ever occurs.

That capability transforms the aftermarket from a reactive service function into a predictive, profit-driving engine. It gives OEMs visibility into the customer’s world and allows them to build value long after the initial sale. In an industry where every hour of downtime costs money, that kind of foresight becomes priceless.

That shift from reactive to predictive service doesn’t just improve efficiency, it fundamentally changes the relationship between OEM and customer. Suddenly the manufacturer isn’t just a supplier, it’s a partner in uptime. That builds trust, and trust is what keeps customers coming back long after the warranty expires.

When machines can “talk”, OEMs can listen, learn and act faster than ever before. They can help customers plan service around utilization peaks, optimize performance across fleets, and even benchmark operational efficiency against industry averages. The result? A deeper, more strategic partnership rooted in shared data, shared outcomes and shared success.

And as customers grow accustomed to this level of insight and convenience, their expectations rise. They no longer want a manual or a hotline number, they want a connected experience. They want predictive alerts, transparent pricing, automated logistics and digital documentation at their fingertips.

Technology isn’t just enabling that shift, it’s demanding it. The bar for service-excellence has been permanently raised.

According to a McKinsey & Company study, aftermarket & service now contributes to a majority of OEM margins, and companies that excel in aftermarket services have achieved something in the region of twice the total shareholder return of those who don’t focus on services.

Technology is redefining the customer experience from the ground up. In an era where every contractor expects digital convenience, OEMs that provide self-service portals, intuitive parts ordering and mobile fleet-management tools are setting a new standard.

Customers can check equipment health, schedule maintenance and track service history with the same ease they’d expect from online retail. It’s simple, transparent and friction-free, and that’s exactly why it works.

Behind that simplicity lies sophistication: integrated systems connecting real-time machine data with back-end parts inventories, logistics networks and dealer management systems. The best OEMs are creating digital environments where everything connects, from the operator in the field to the technician en route, right back to the factory floor.

“Customers can check equipment health, schedule maintenance and track service history with the same ease they’d expect from online retail. It’s simple, transparent and friction-free, and that’s exactly why it works.”

Meanwhile, OEMs without digital connectivity find themselves in a defensive posture. They’re slower to respond, disconnected from real-time data and often reliant on outdated service-processes. Competitors with connected platforms move faster, offer better uptime guarantees and quietly pull ahead.

That gap is widening, and it is widening quickly.

For example, global consultancy Kearney says: “Aftermarket services are becoming a powerful way to boost revenue for manufacturers of products that have a long lifespan… after-market services are projected to grow faster than overall product sales, and faster than GDP.”

The future belongs to those who see machines not as isolated assets but as nodes in a connected ecosystem. By linking dealers, service partners and suppliers through shared-data platforms, OEMs can deliver seamless support from factory to jobsite. Everyone in the chain, from logistics teams to technicians, works from the same live data, making service faster, more accurate and more profitable.

Shared platforms create new possibilities. Dealers can see the same diagnostic insights as OEMs. Parts distributors can prepare inventory based on predictive demand. Service teams can arrive on-site already knowing what needs fixing. It’s a coordinated, intelligent approach, turning fragmented operations into an orchestrated, customer-first network.

For OEMs, this connectivity brings control back into their ecosystem. Instead of ceding aftermarket share to independents, they can capture value through quality-assurance, brand consistency and data-driven service performance. The aftermarket becomes not only a revenue stream, but a strategic moat against potentially more nimble competition that strengthens with every connected machine.

The OEMs flourishing in today’s market see technology not as an add-on but as the foundation of their aftermarket strategy. They’re leveraging predictive maintenance to boost parts sales, AI-driven analytics to forecast demand and digital-commerce to keep customers within their ecosystem.

AI is now identifying usage patterns that predict wear on components months in advance. Machine-learning models are recommending maintenance intervals tailored to specific environments, while automation ensures that replacement parts are shipped before the customer even realises they’re needed.

These aren’t abstract concepts. They’re the new competitive baseline. Every connected insight improves the customer experience and strengthens the bond between OEM and operator. Every missed opportunity to act on that insight is an invitation for someone else to step in.

Connectivity and intelligence are rewriting the economics of customer relationships. In a connected aftermarket, the value isn’t just in selling a part, it’s in keeping the machine productive, the customer loyal and the data flowing.

This model rewards consistency, reliability and foresight, qualities that technology amplifies. OEMs that can deliver on these fronts become indispensable partners. Those that can’t will increasingly compete on price alone, a race that few can win.

“Those still hesitating risk being left behind, watching as their competitors turn every machine, every sensor and every service event into a long-term value stream.”

The aftermarket is no longer an afterthought, it’s the foundation of modern OEM profitability. The ones thriving today have already made the leap, transforming data into loyalty and connectivity into growth.

Those still hesitating risk being left behind, watching as their competitors turn every machine, every sensor and every service event into a long-term value stream.

Because in the connected era, the aftermarket isn’t a side business — it’s central to the entire earnings plan.

If you want to turn aftermarket potential into a practical plan, the next article breaks down the building blocks of an effective OEM aftermarket strategy.