Creating an accurate construction cost estimate is essential for staying on budget, minimizing risks, and ensuring project success from start to finish.

Construction project managers have a lot on their plates both logistics and cost-wise. They are in charge of hiring and paying the right AEC (architecture, engineering, construction) and contracting teams, acquiring materials, obtaining permits, and completing everything within a set timeframe.

Most managers use a construction cost breakdown to stay organized. These breakdowns allot fractions of the budget to the various parts of the process, helping owners finish their projects on budget and contractors protect their profit margins.

This article will look at what a cost breakdown is and what should be included. We’ve also included some examples below to help you better understand and evaluate your next project cost breakdown.

Preparation is key, especially in a sector with a high potential for unforeseen challenges.

A construction cost breakdown is a comprehensive list showing the costs of every expense in a construction project. It divides everything into categories like labor, materials, equipment, and overhead costs, helping construction managers put every dollar to good use.

Proper breakdowns and budgeting help managers plan and schedule the project, identify cost-saving opportunities, and avoid financial risks early in the build process so the project stays within the budget.

It also helps increase transparency and accountability between stakeholders. With an accessible cost breakdown, clients, contractors, subcontractors, managers, and owners can stay on the same page.

There are many factors to consider when it comes to a construction project cost breakdown. It’s not uncommon to feel overwhelmed by the process. We’ll organize it into components to help you out.

There are three types of costs:

So, what is the breakdown of costing in construction? Here’s a look at the different expenses to consider. We’ve also included a construction cost percentage breakdown for a general idea of how much you can allot to each. Important note: These numbers are estimates; percentages can be adjusted based on specific project characteristics and conditions.

Workers and AEC teams won’t work for free. Labor can account for up to 40% of the budget, with wages, benefits, and training for skilled and unskilled laborers.

This category includes:

It also includes the time spent planning, supervising, and managing construction projects.

Materials are the costs of raw goods that will be used during the build. These include raw, foundational materials such as wood, steel and concrete, as well as paint and fixtures.

Prices can fluctuate significantly based on market conditions, meaning managers should monitor prices carefully to source materials as cost-effectively and environmentally conscious as possible. This can help construction businesses meet their budget and sustainability goals.

Precise estimation is key to keeping things on budget.

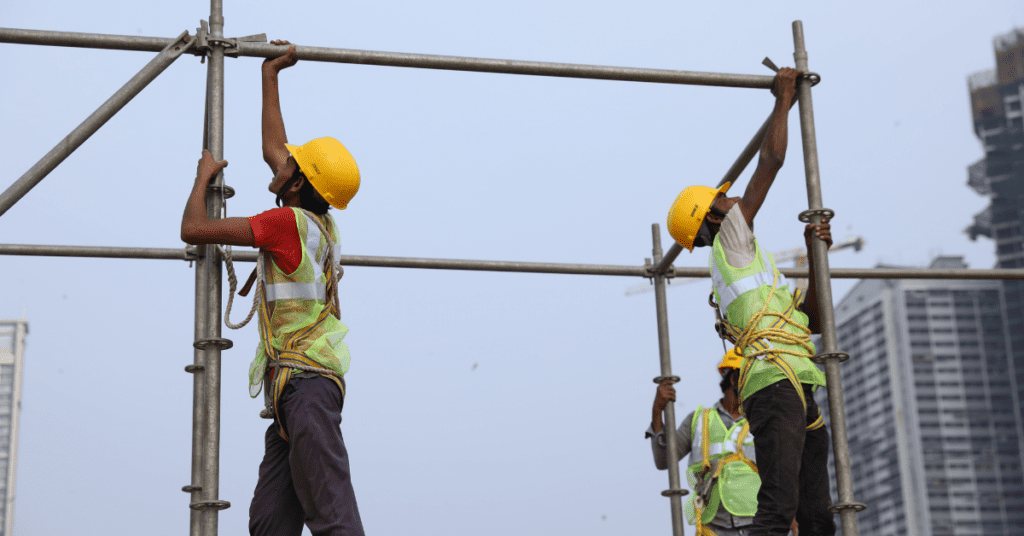

This category involves all the construction machinery and tools you will need to build your structures, from excavators and cranes to hand tools and safety equipment.

To save money on storage and ownership, some construction businesses rent heavy machinery for projects. If you choose to, remember to factor the right costs into the budget as well.

Wise management involves considering different rental options, maintenance schedules, and lifespan of machinery to optimize your investments.

It’s important to separate materials and equipment costs. Sometimes, there can be a gray area between the two, but do your best to split them for an accurate cost estimate.

Overhead costs encompass all the background expenses required to keep a construction business operating but are not directly attributed to specific projects. This includes office rent, utilities, taxes, marketing, administrative salaries, and software subscriptions.

Consider these as part of the budget since they are necessary to keep your construction business afloat.

These are some of the expenses critical to the feasibility and compliance with local regulations. Companies must obtain the necessary permits to build and cannot lay a single brick without them.

Also note the region you are in, as different geographical areas will have different regulations to adhere to.

These are the necessary services and supplies that keep your project and job site efficient and secure.

This category includes the cost of setting up necessary utilities, IT infrastructure, workplace safety signage, and security installations (cameras, drones, staff, etc.). Managing these costs helps ensure your project is safe even after hours.

Construction is complex, and sometimes unforeseen issues arise. Think of this as your financial safety net to protect your bottom line from unpredictable hurdles. Allocating a portion of your budget as a backup fund allows you to adapt without compromising project quality or financial viability.

As you begin to consider the type of structure you want to build, it’s important to start budgeting for pre-construction costs, and unexpected ones too.

Several factors can influence a construction cost estimate, including project scope, size and location, and the state of the market. Here’s a look at things that can impact pricing.

Additionally, the climate region may impact the price of materials and finishes. For example, the need for durable and weather-resistant materials and finishes may cost more in the northern and Midwest regions of the US, where snow and ice storms are more common.

Regions prone to natural disasters may require specialized construction techniques and materials.

Price and availability of materials: The cost of construction materials can also fluctuate due to global and market trends. Supply shortages and higher demand can drive up prices, affecting the budget. Additionally, the availability of materials may influence the choice of construction methods and timelines, potentially leading to increased costs.

It’s a good idea to estimate the total construction cost of your project.

While there’s no one-size-fits-all solution to estimating construction costs, there is a general process that most construction teams follow before they start building. Here’s a quick guide on how to price a construction project.

Tips for best practices:

To help explain, we’ve provided a construction cost breakdown example.

Due to an influx of children in a newer residential area in Southern California, the state has decided to build another high school, which costs about $463 USD per square foot according to recent statistics from this year.

Using the unit pricing method (finding each cost per square foot), if the school is to be 200,00 sq. ft., the total cost of the project would be:

200,00 sq. ft. x 463 = $92,600,000 USD ($92.6 million USD)

The following cost breakdown table gives an approximate guideline for this project:

| Usage | % | Cost (USD) |

| Labor | 20-40% | $18.5 – 37.04 million |

| Materials | 30-40% | $27.78 – 37.04 million |

| Equipment (rental or purchase) | 5-10% | $4.63 – 9.26 million |

| Overhead costs | 5-10% | $4.63 – 9.26 million |

| Permits, regulations, etc. | 2-5% | $1.85 – 4.63 million |

| Vendor | 2-5% | $1.85 – 4.63 million |

| Contingency | 3-10% | $2.78-92.6 million |

| Project X | Total cost: $92.6 million (at $463 per sq. ft.) |

A residential or commercial construction cost breakdown would be similar; first identifying the project size scope, then calculating the pricing per square foot.

Here at Trackunit, we understand that efficient, cost-effective construction is better construction. We have a suite of tools built to streamline your processes and boost productivity so you can deliver better results faster.

We also understand that since most modern construction can’t be done by hand, your equipment is essential to the success of your project. Downtime is one of the toughest challenges in construction today — when your machines don’t work, neither can you.

Our software is specifically designed to connect your machine fleet so project and fleet managers can keep their equipment up, running, and ready to use.

Trackunit Manager provides you with a total overview of your entire fleet. This solution helps you track the movement and status of your vehicles from a customizable dashboard.

Trackunit Go, a portable version of this solution, gives you complete visibility of your entire fleet of vehicles. Managing or renting out vehicles across multiple job sites? No problem. Our solutions harness the power of GPS tracking and real-time alerts, so you can keep tabs on each machine’s location at any time of the day, minimizing idle time and theft.

Trackunit Go’s intuitive map shows you exactly which assets are currently working, moving, or stopped and even provides a turn-by-turn navigation option to quickly locate malfunctioning equipment.

Trackunit Go makes it easy to approve scheduled services with just one tap, and add new maintenance schedules from the same platform. For equipment with a CAN bus connection, you’ll see advanced sensor values like fuel consumption, engine speed, oil temperature, etc., in a simple, user-friendly layout.

For more information on how we can eliminate downtime on your job sites or to request a demo, fill out the form below.

Cost Breakdown Structure, also known as CBS or “should-cost analysis” is a comprehensive document that helps track and manage the various expenses of a project. It’s a great tool to keep stakeholders in the loop by categorizing expenses and increasing transparency.

A project’s cost breakdown consists of all expenses required for its completion, including but not limited to materials, labor, equipment, services, administrative expenses, and any unforeseen costs that may arise during construction.

To calculate the cost of a project, assess and combine the hard and soft costs (direct and indirect project expenses), vendor expenses, and estimated operational costs, while also allocating resources for any potential unexpected expenses.

Multiply the size of your projected project by the cost by square foot for an approximate total cost to complete the construction job.

These terms are often conflated, but they mean different things. A project budget is the estimation of the total cost and can be subject to change. Conversely, a baseline is an approved budget and is set in stone.

Learn how Trackunit can help you stay on budget by reducing downtime by visiting here.