When you’ve enjoyed a history as long as Spain-headquartered AUSA, there tends to be a common thread of good decisions through the years, like investing in a robust IoT solution ensuring it has enjoyed steady expansion and a growing customer list.

And it is with that same, careful plotting that the manufacturer of industrial equipment, opted for global IoT player Trackunit as its partner. It does after all have a diverse product portfolio including dumpers, rough terrain forklifts and compact telehandlers and takes seriously its mission of providing customers with high-tech solutions that prioritize performance and reliability.

“We launched the AUSAnow solution together with Trackunit during 2021,” Roger Rotés, Product Manager at AUSA says. “The partnership between AUSA and Trackunit exemplifies the power of collaboration in driving operational excellence and customer satisfaction.”

Together, Trackunit and AUSA embarked on a journey to revolutionize AUSA’s operations, which are globally extended. The result? “A seamless integration of high-tech solutions and money-saving measures weave into the AUSA product portfolio,” says Rotés.

“Eliminating downtime is something very important right now. The Trackunit solution helped us digitize our processes and equipment tracking.”

Roger Rotés, Product Manager

When AUSA partnered with Trackunit, it recognized the need for a robust IoT solution to optimize its fleet management processes.

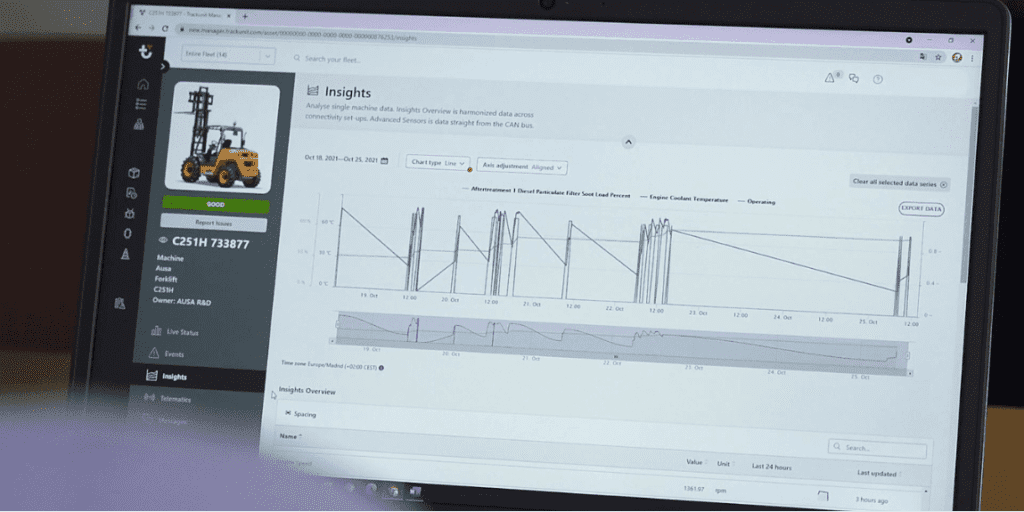

The partnership was about digitizing processes, leveraging data to refine designs, engineering, and ultimately, enhance customer experiences. “So right now, AUSAnow is not only bringing in customers with a telematics solution, but we are using the information we get from our machines to know how the machines work,” Rotés says. It was about going beyond the surface, diving deep into the intricacies of machine functionality.

The collaboration didn’t stop at basic GPS tracking; it went deeper, developing tailored CAN bus data profiles for electric and diesel machines. These profiles became instrumental in slashing downtime, a critical factor in the industrial realm. Rotés says that it wasn’t just about knowing where the machines were; it was about understanding how they operated — insights that empowered customers to make informed decisions.

A standout feature of AUSA’s offerings is its proprietary transmission system, designed to power machines electrically or by diesel. “Since the beginnings of our company, one of our differentiating factors has been that we design and manufacture our own transmissions for the most compact vehicles,” Rotés says. This innovation provides AUSA with the flexibility and ease to create new products in an agile manner.

“Trackunit helped us adapting their own solution to our needs. So right now, AUSAnow is not only bringing in customers with a telematics solution, but we are using the information we get from our machines to know how the machines work.”

Roger Rotés, Product Manager

Through Trackunit’s IoT solution, particularly Trackunit Manager and Iris, AUSA gained access to a centralized IoT platform for monitoring and managing their entire fleet, streamlining operations and saving administrative time. With AUSAnow, AUSA and Trackunit developed tailored profiles for both electric and diesel machines, effectively reducing downtime for customers.

The utilization of Trackunit Iris perfectly aligns with AUSA’s objectives of enhancing operational efficiency and customer satisfaction. Just as Trackunit Iris is designed to scale with businesses as they grow, AUSA leverages this scalability to expand its market presence and introduce new products.

The platform’s hardware-agnostic nature allows AUSA to connect a diverse range of equipment, enabling comprehensive fleet management and optimization. Trackunit Iris facilitates AUSA’s digitization efforts by providing a secure and reliable foundation for data management and analysis.

This IoT solution empowers AUSA to make informed decisions in design, engineering, and customer service, ultimately driving innovation and differentiation in the competitive construction industry. With Trackunit Iris, AUSA harnesses the power of connectivity to streamline operations, enhance equipment performance, and deliver exceptional value to its customers.

Looking ahead, AUSA remains steadfast in its commitment to innovation, IoT device management, and market expansion. “We are dealing with some new products and technology that we are introducing into the market,” Rotés says. “The journey doesn’t end here — it’s a continuous push towards deeper market penetration and brand prominence.”

Founded in 1956 in Barcelona, Spain, AUSA is a leading manufacturer of compact all-terrain industrial vehicles, including dumpers, forklifts, and telehandlers. Operating in over 90 countries through a network of over 600 dealers, AUSA is renowned for its robust and innovative solutions across various industries. The AUSAnow program exemplifies its commitment to customer satisfaction, offering comprehensive service, support, and access to spare parts to ensure optimal performance and longevity of its machines.

Founded: 1956

Size: Approximately 350 employees

Hear more of the Trackunit Customer Success stories now.