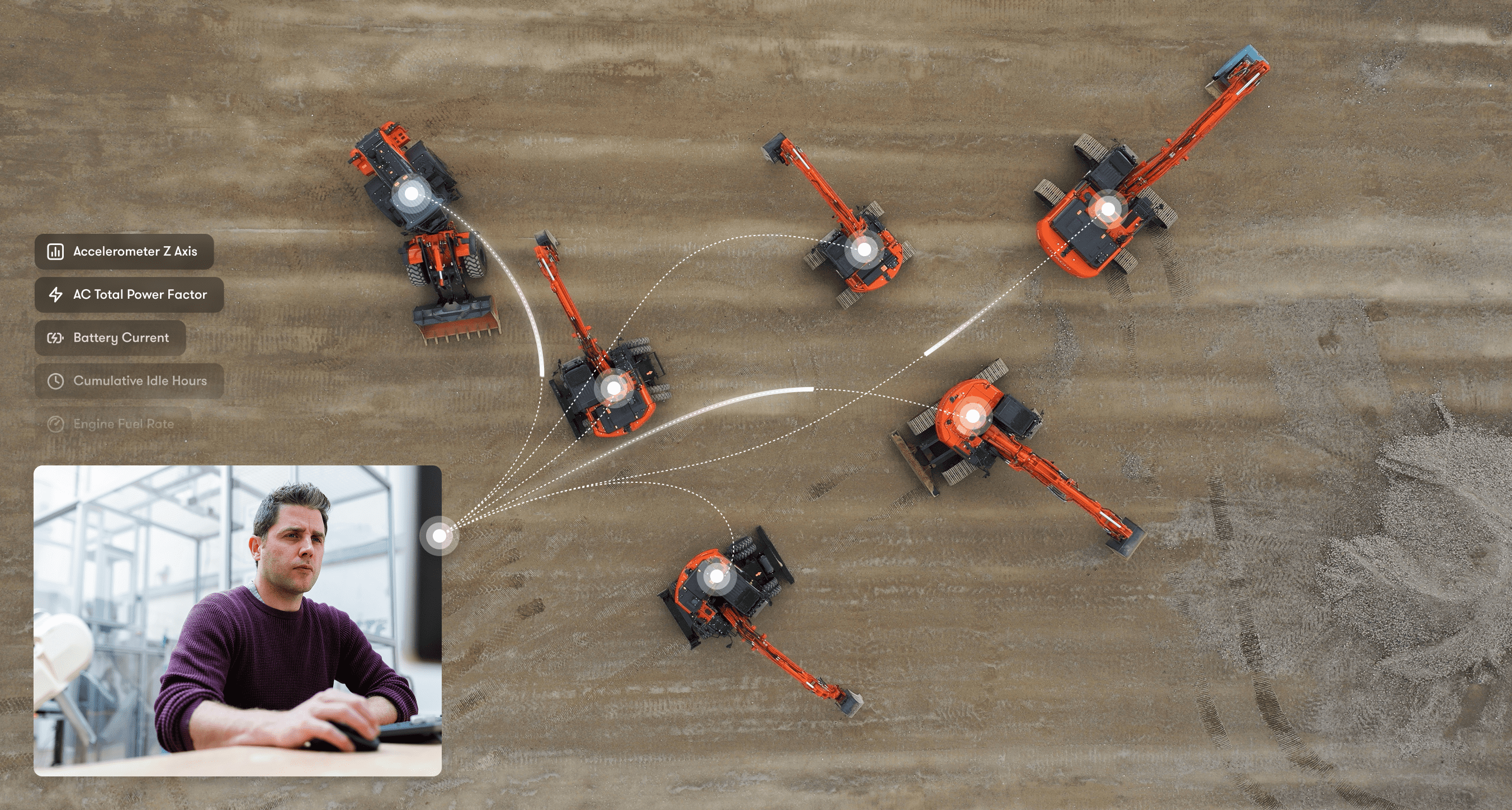

From factory installation to full-fleet visibility

Supporting your telematics journey every step of the way. Access real-time data, deliver remote diagnostics, and unlock actionable insights to build better machines, support your customers, and grow aftermarket part sales.

Turning connectivity into your competitive edge

Use real-world machine insights to improve product design, enhance support operations, drive parts sales, and grow long-term brand value.

Sell more parts

Shift from reactive cycles to proactive sales. Use machine data to forecast demand and stay ahead of your customers.

Drive branded value

Develop custom insights to build trust and loyalty. Help customers understand machine performance and boost trust.

Design with real-world data

Design from actual use, not assumptions. Use shared machine insights to improve features and meet market needs.

Support from anywhere

Reduce site visits with remote diagnostics. Give teams visibility into machine health to save time and fix issues faster.

Trusted by leading equipment professionals

Learn more about how you can unlock branded experiences, custom insights, and hands-on support that help your machines stand out.

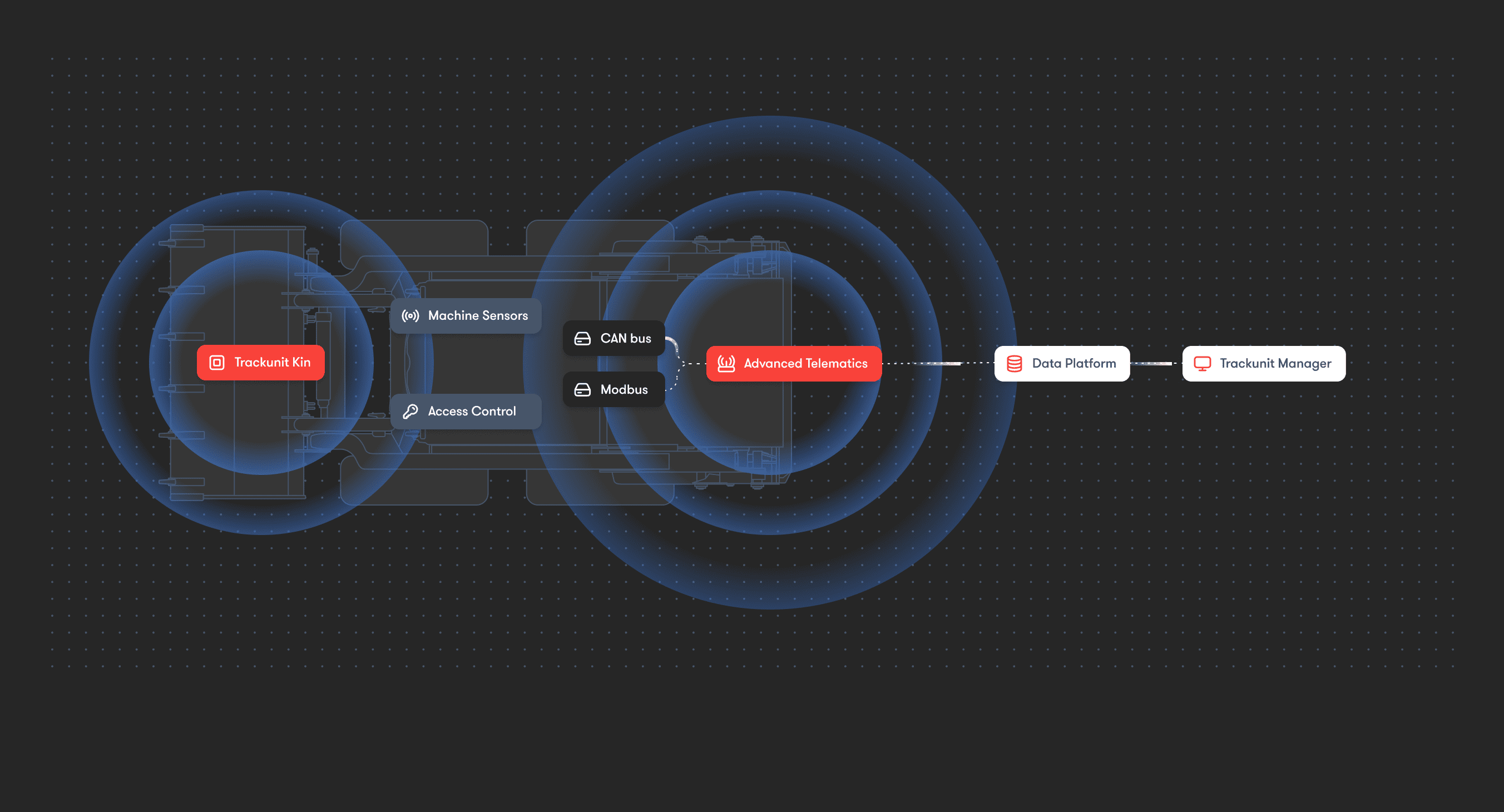

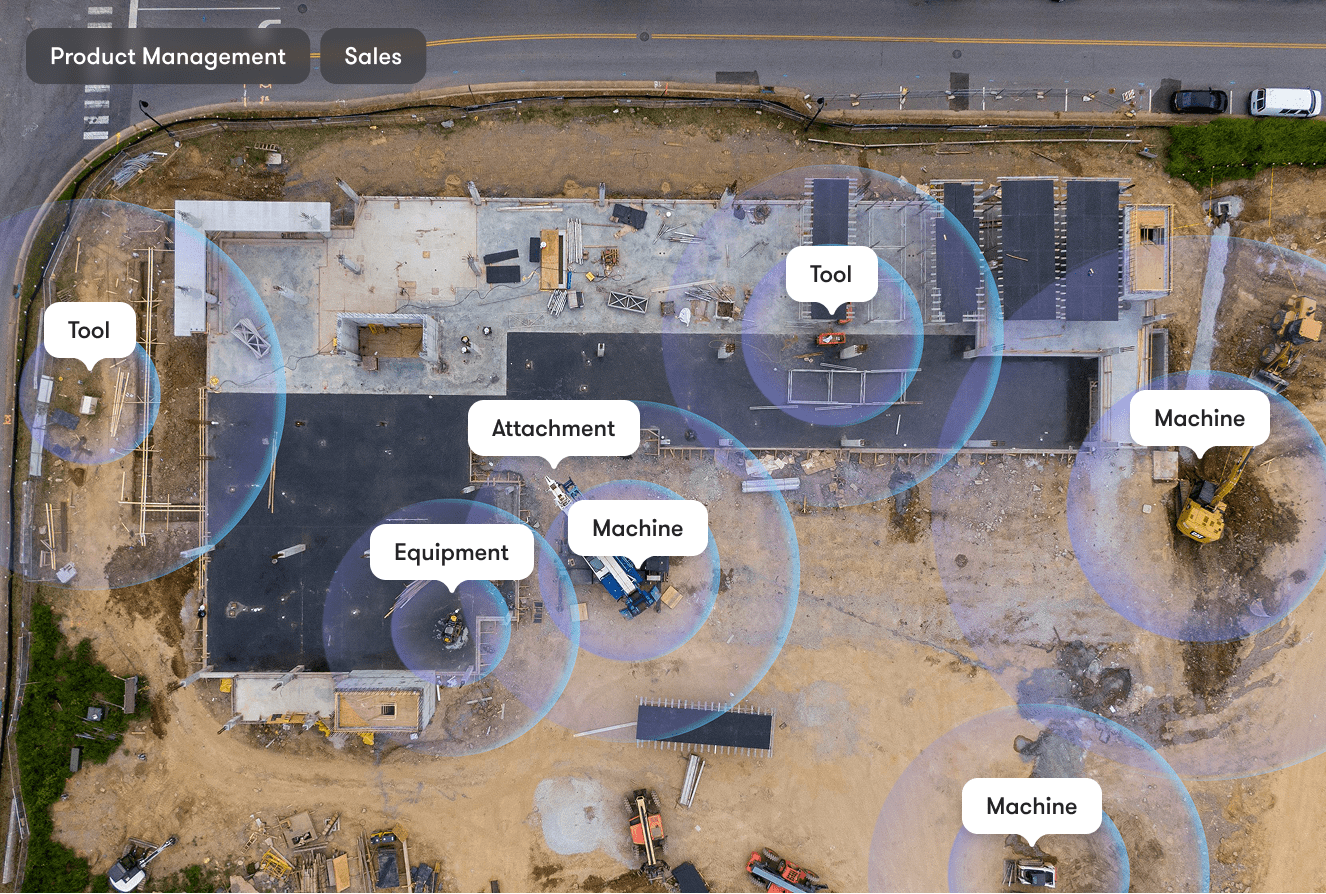

Telematics for every type of construction asset

Created for all OEMs. Connect, support, and grow your full portfolio, from heavy machines to handheld tools, through a single platform designed to scale.

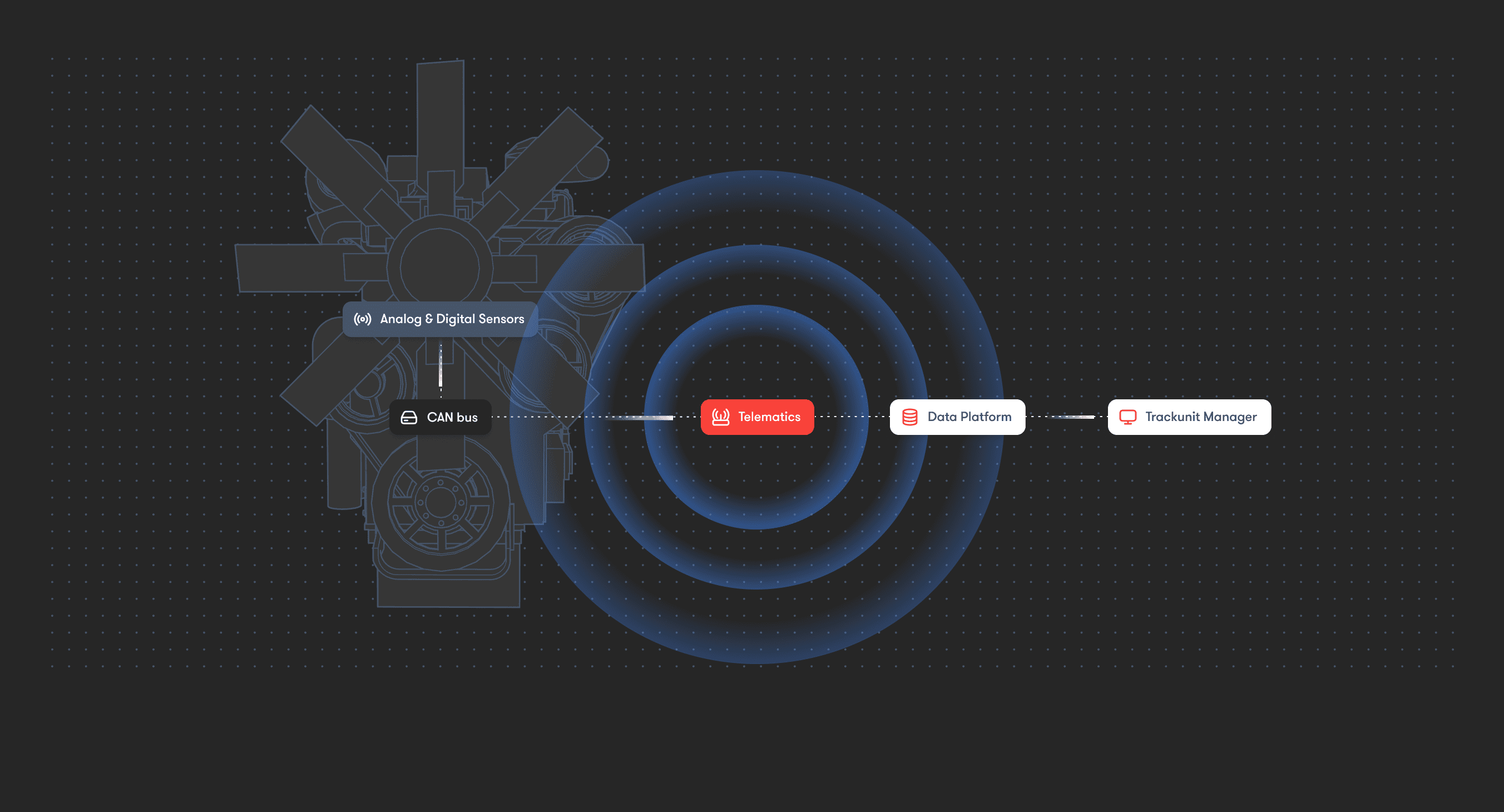

Inputs

Gather real-time data on machine health, usage, and location to optimize performance and prevent downtime.

Reduce unplanned downtime by up to 30% when using sensor-driven predictive maintenance

Telematics

Turns equipment data into insights that improve support, reduce downtime, and boost fleet productivity.

Cut maintenance costs by up to 25% through predictive service scheduling and usage-based diagnostics

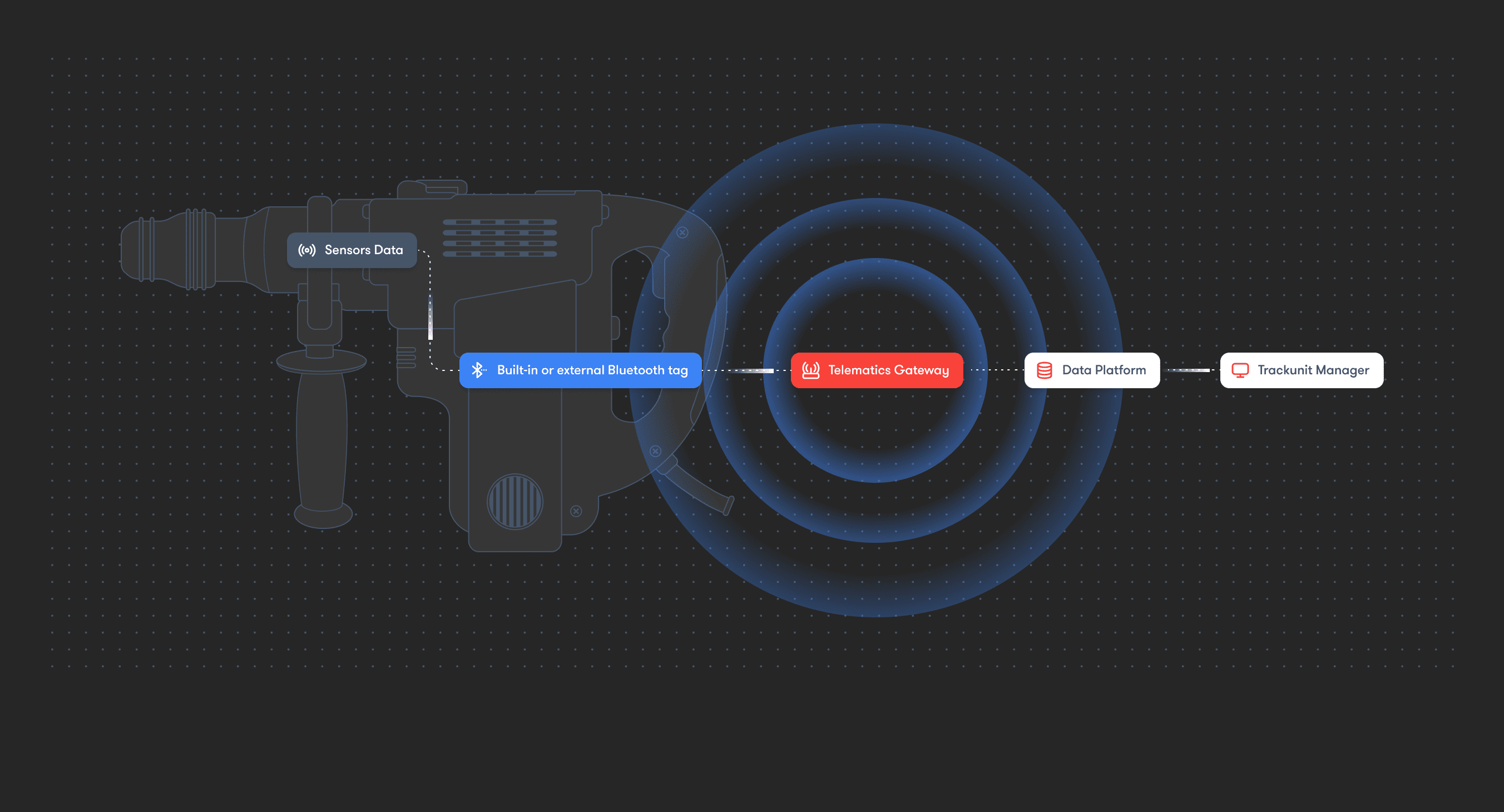

Communications

IoT devices transmit asset data from the field to the cloud using cellular, satellite, or Bluetooth technology.

OEMs deploying multi-modal communication reduce data blind spots by up to 80% across complex worksites and locations.

Data Platform

One central location for asset data, enabling analytics, integrations, and scalable solutions for every OEM fleet.

OEMs integrating assets on a unified platform report a 40% faster time-to-market for digital services and new customer offerings

Map

Explore, identify, and address equipment needs with real-time status and location insights, in a streamlined, interactive view.

10% of an average workday is wasted searching for tools and equipment.

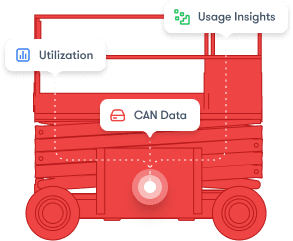

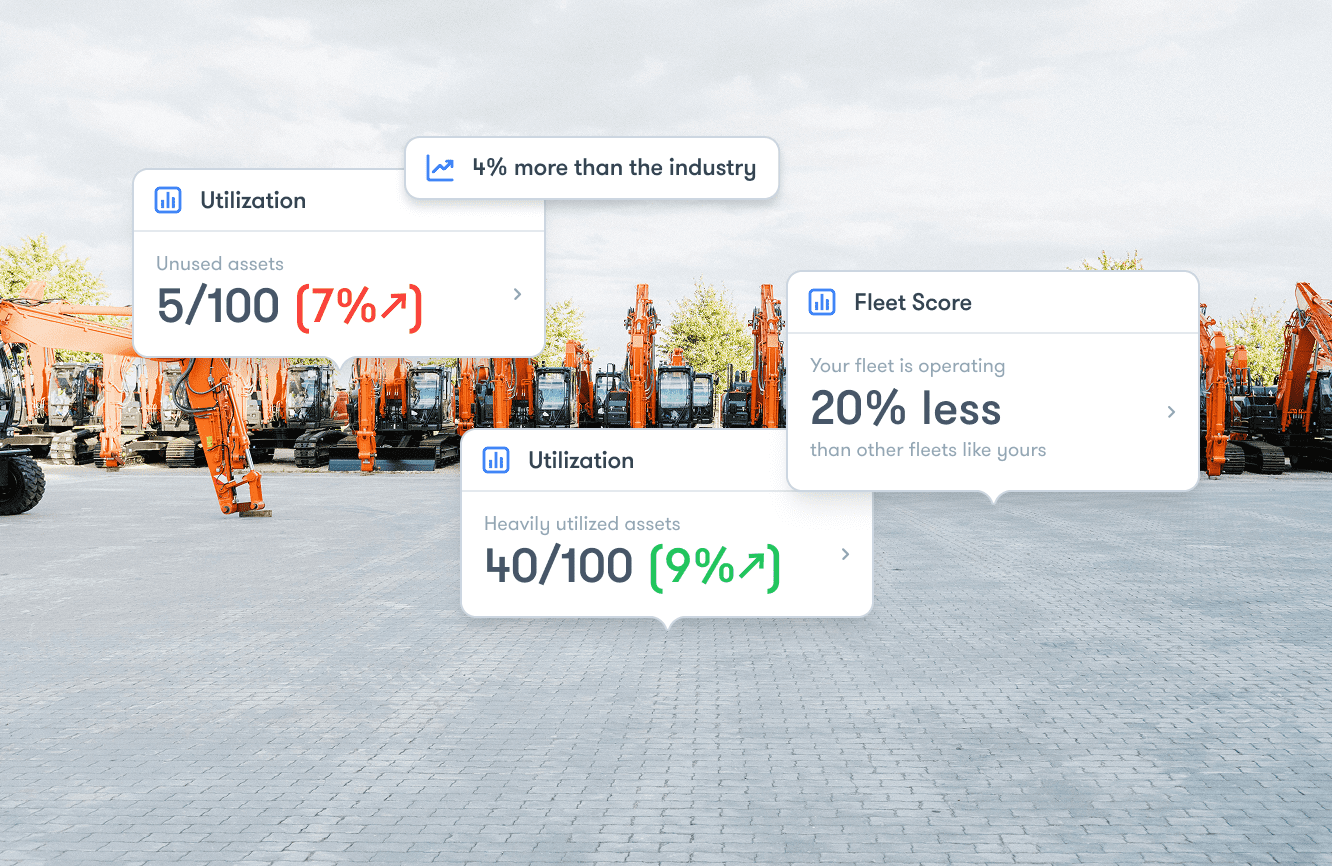

Utilization

Stop guessing and take control of costs, productivity, and performance with clear equipment usage information in hand.

8% increase in repeat business through improved customer utilization.

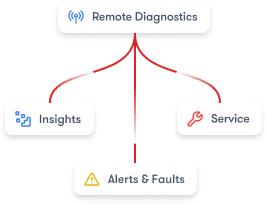

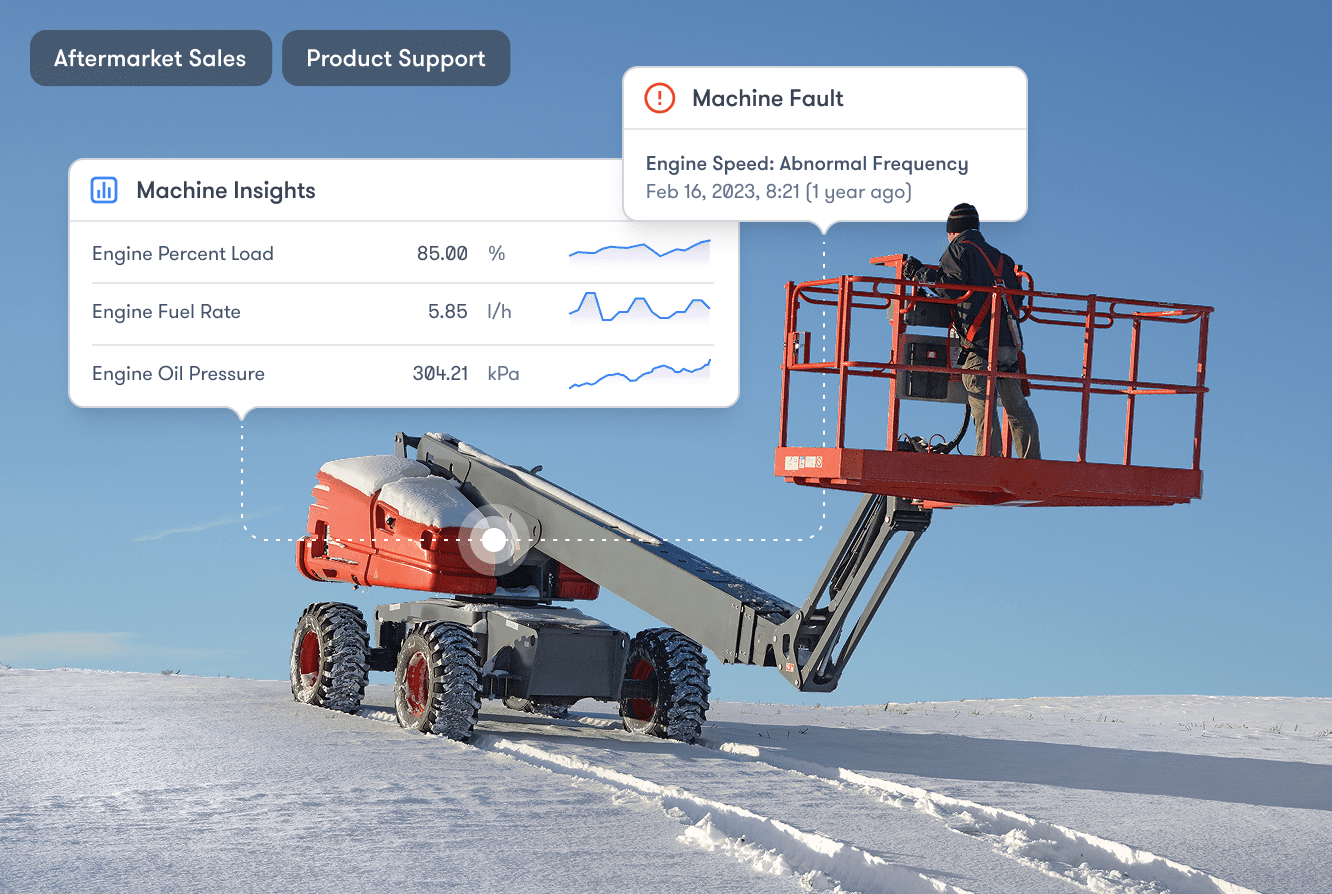

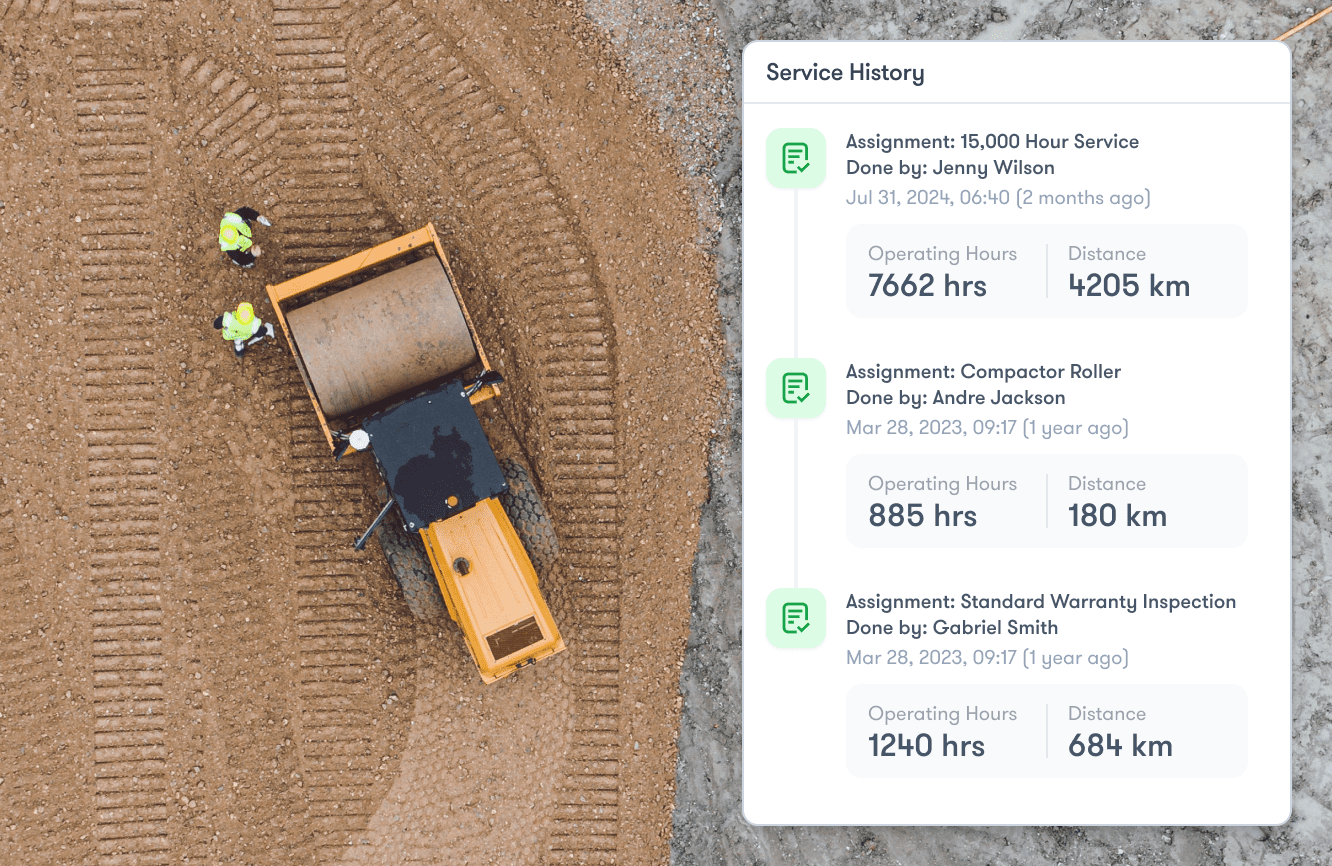

Health

Remotely diagnose the health of your equipment with detailed insights and take immediate action on potential break downs.

Reduce equipment downtime up to 50% with proactive insights.

Alerts

Proactively keep assets moving at all times by configuring notifications to bring critical machine conditions to the forefront.

Save $10,000–$25,000 on each heavy equipment failure avoided.

Making data more accessible to drive more revenue

Power your machines and your brand with digital capabilities that drive better design, faster service, and actionable insights across your teams.

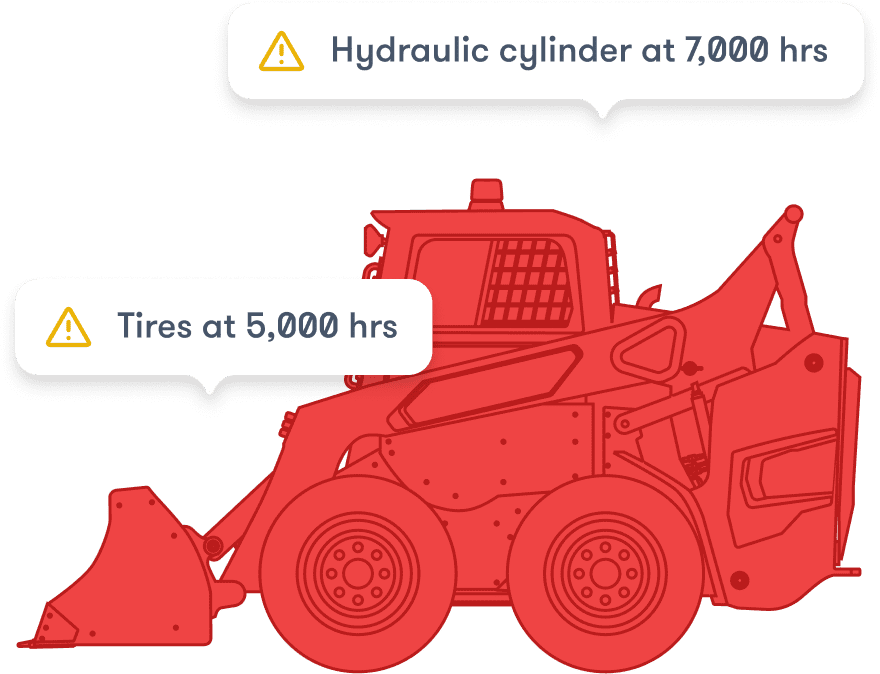

Drive parts revenue with a proactive service approach

Turn machine usage data into timely parts sales and premium service plans. Monitor hours, cycles, and behaviors to alert customers before failures to increase uptime and strengthen loyalty.

Connect every asset from machines to tools and attachments

From machines to tools and attachments, bring every asset online. Offer total fleet visibility and benchmarking performance that helps rental and contractor customers optimize operations.

Reduce service costs with mobile-first visibility

Give technicians real-time access to machine health, diagnostics, and location from any device. Remote visibility cuts travel time, speeds up response, and lowers the overall cost of support.

Build machines that match real-world requirements

Use machine usage data from the field to guide smarter product design decisions. By aligning design with real-world behavior enables you to focus on features that matter, reduce complexity, and get new machines to market faster.

Seamlessly integrate with a digital ecosystem your customers rely on

Make your machines work in your customers’ preferred platforms. Use APIs and apps to help customers connect quickly, automate workflows, and keep your machines at the center of the jobsite.

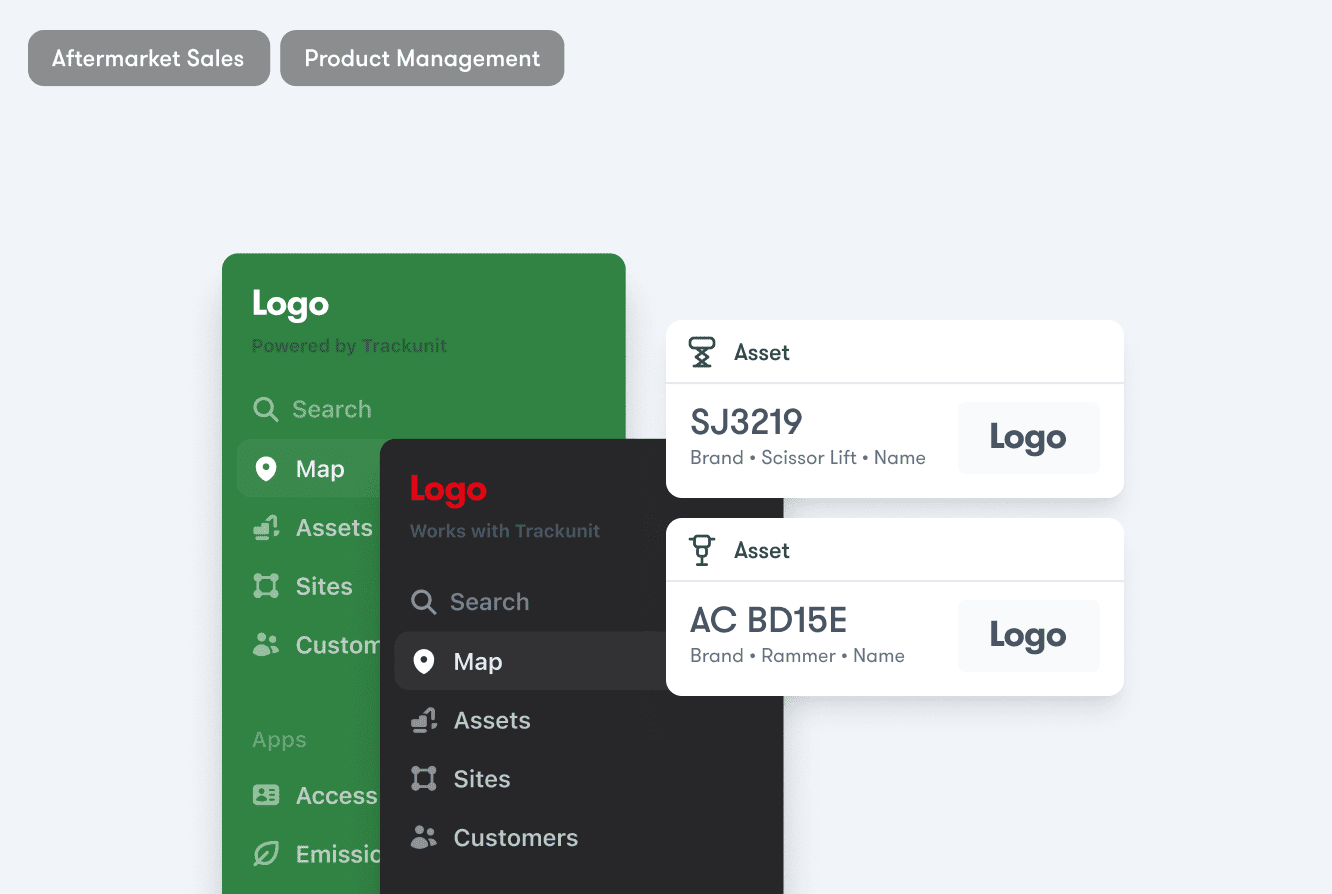

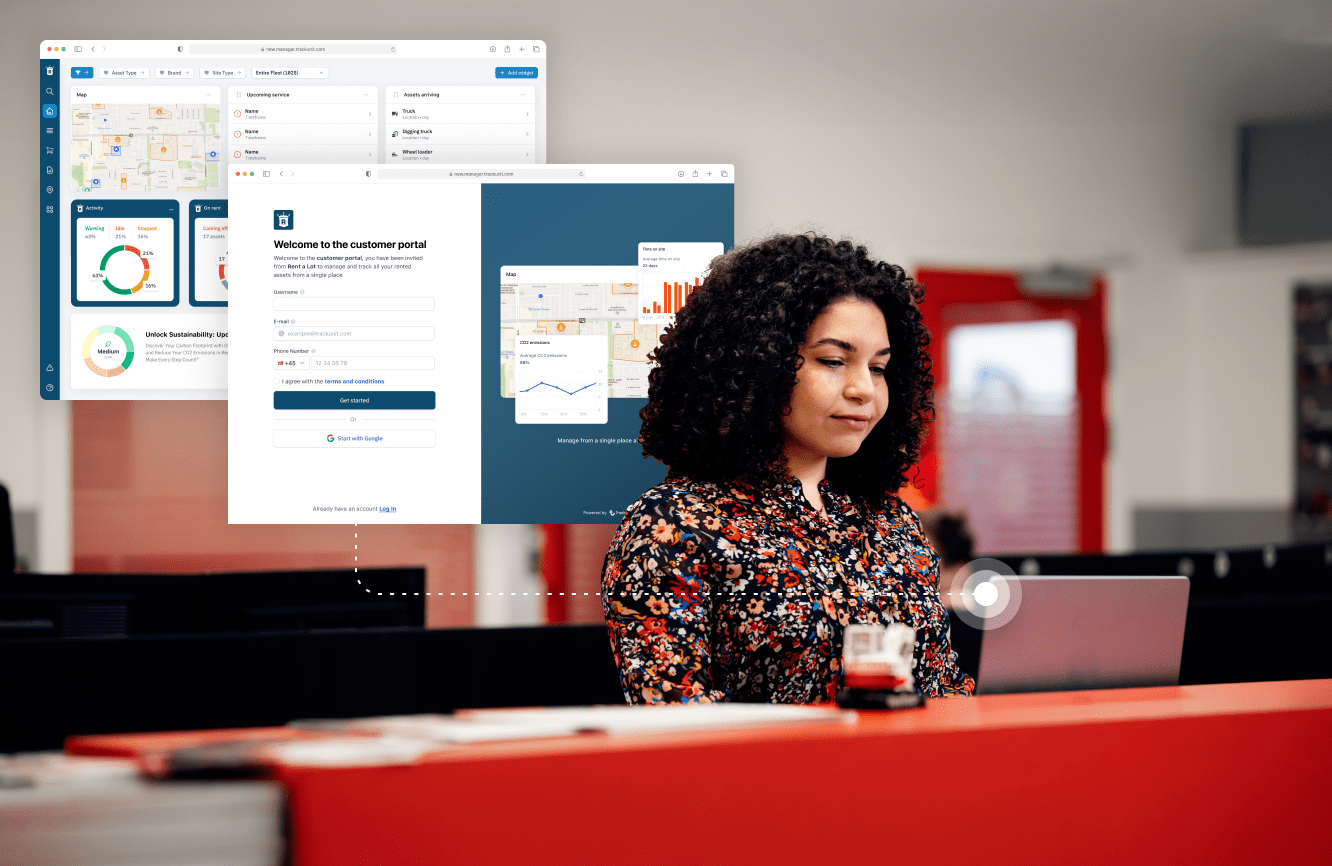

Deliver branded insights and a consistent digital experience

Create a custom-branded presence in Trackunit Manager with machine visuals and custom insights your customers rely on. Deliver a consistent experience and control how your brand shows up.

Built for impact

Accelerate design with data

20–30%

Regain lost opportunities

40%

Eliminate blind spots and take control of your data

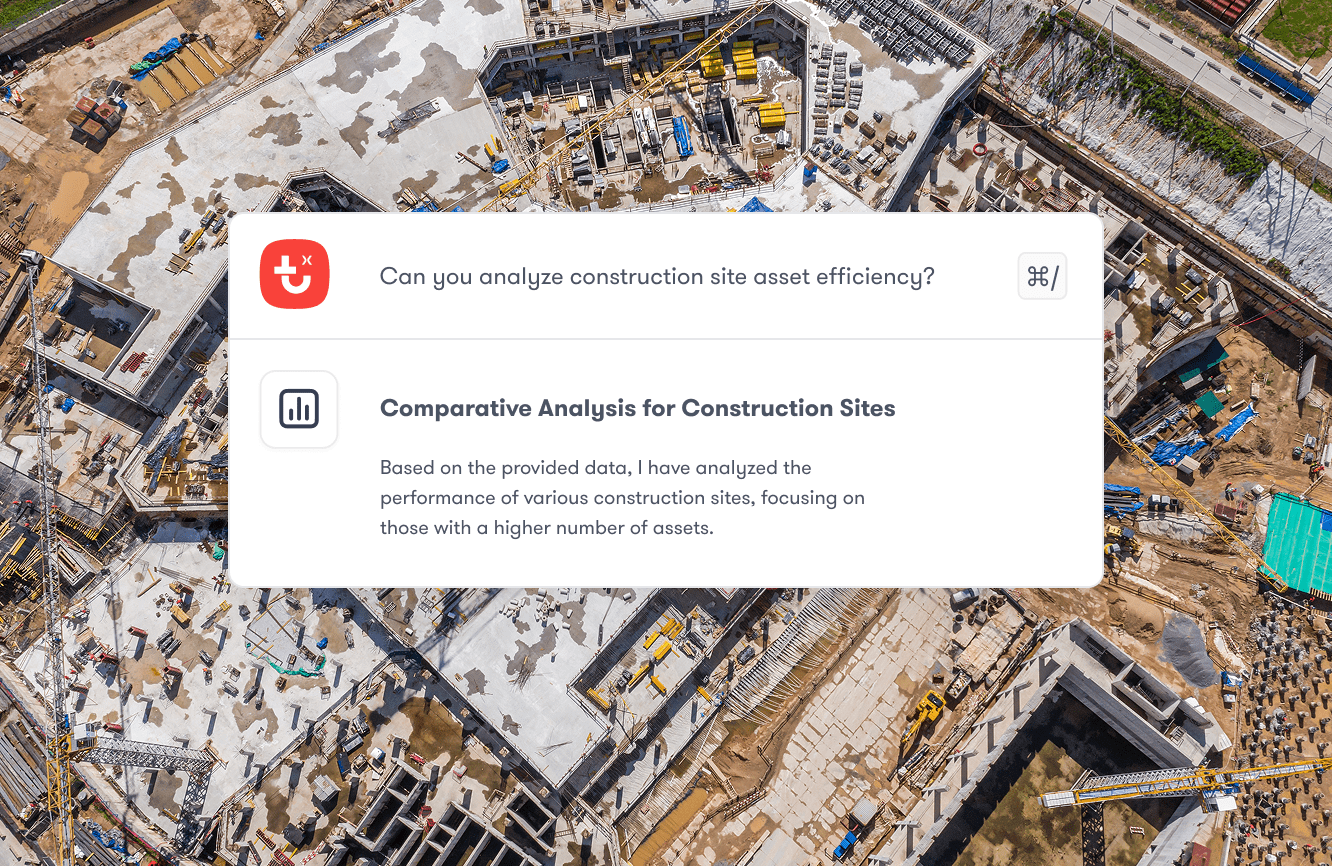

With IrisX, OEMs gain complete operational visibility across machines and markets. Aggregate and harmonize disconnected data, understand true machine usage, and take control of parts and service cycles with faster, smarter decision making.

AI-Ready

Elevate your operational capabilities

Advance the value creation process with IrisX to automate tasks, enhance predictive capabilities, and drive data into action.

IrisX Blueprints

Market demand forecasting

Real-time market demand forecasting based on machine usage and dealer insights to help hone your inventory and go-to-market planning.

IrisX Blueprints

Warranty Management

Increase revenue with extended warranty contracts with targeted campaigning prior to warranty expiration.

IrisX Blueprints

OEM customer & dealer portal

Seamless collaboration and asset management through a unified, scalable, and mixed-fleet experience.

Join the network that works with the entire industry

The Works With Trackunit Program helps OEMs, component makers, and tech providers validate compatibility and connect with a broader ecosystem. Be part of a trusted, open platform that ensures your machines, tools, and systems work seamlessly in mixed fleets and across the jobsite.

Built for all OEMs, from bolts to booms

Whether you build compact tools, heavy machines, or critical components, you can connect your products, deliver insights to customers, and expand your digital offering.

Machines

Connect, monitor, and support every machine across its lifecycle.

Components

Deliver smart, integrated components that power OEM and customer insights.

Tools

Bring compact tools into full fleet visibility with Bluetooth connectivity.

Capabilities & insights

Developer Hub and SDK

Geo-fencing and site-level intelligence

Marketplace App integrations

Real-time GPS

Smart alerts and automation

Theft prevention and recovery

Equipment health

—

Utilization insights and reporting

—

Digital Access Management

—

—

Fleet-wide emissions reporting

—

—

Fuel usage and idle reporting

—

—

Operator behavior patterns

—

—

Preventative maintenance and service

—

—

Wear-and-tear indicators based on usage

—

—

Request a Demo

Let’s connect and find the right time and place for a demo to explore your connectivity potential.