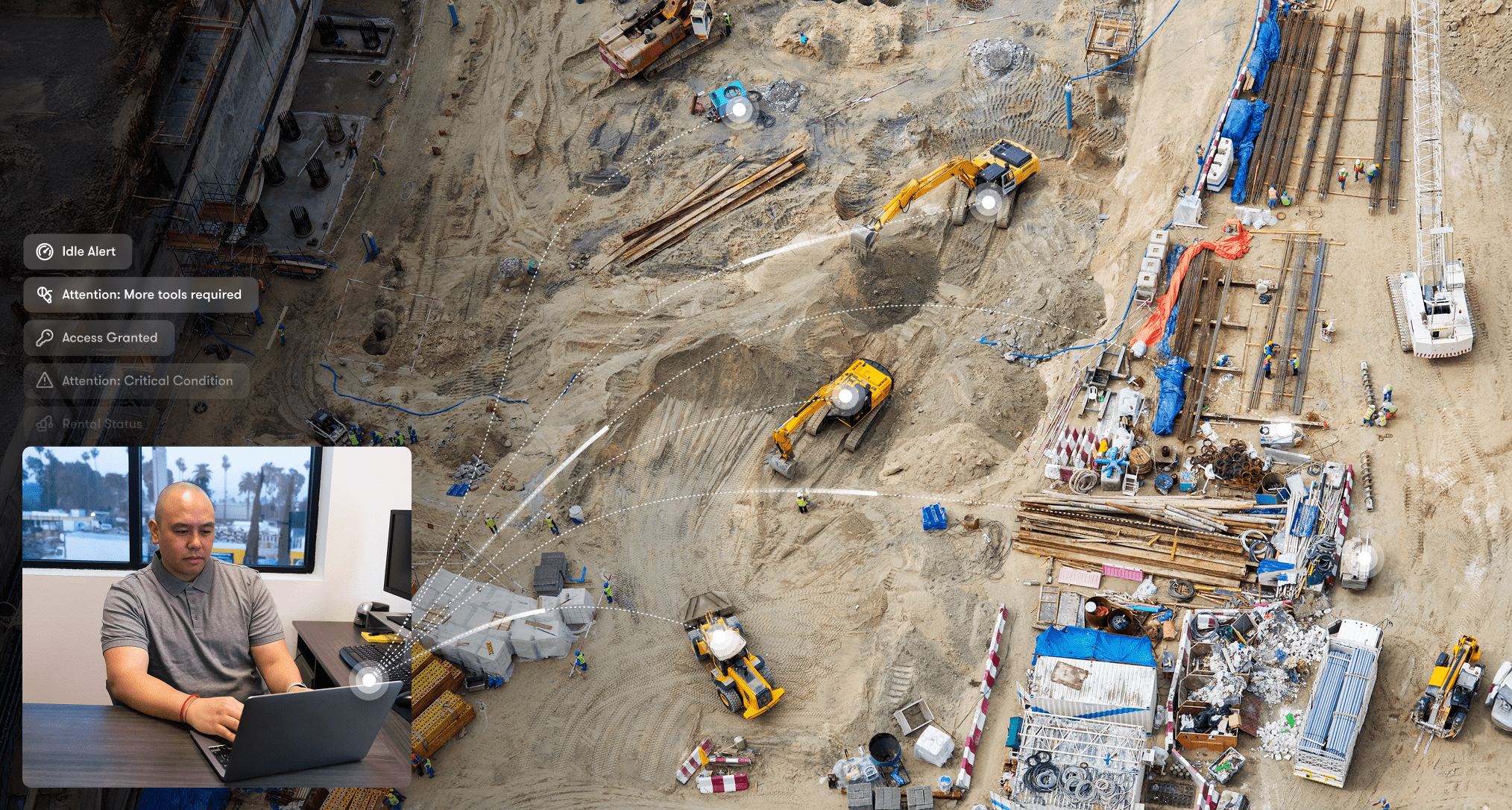

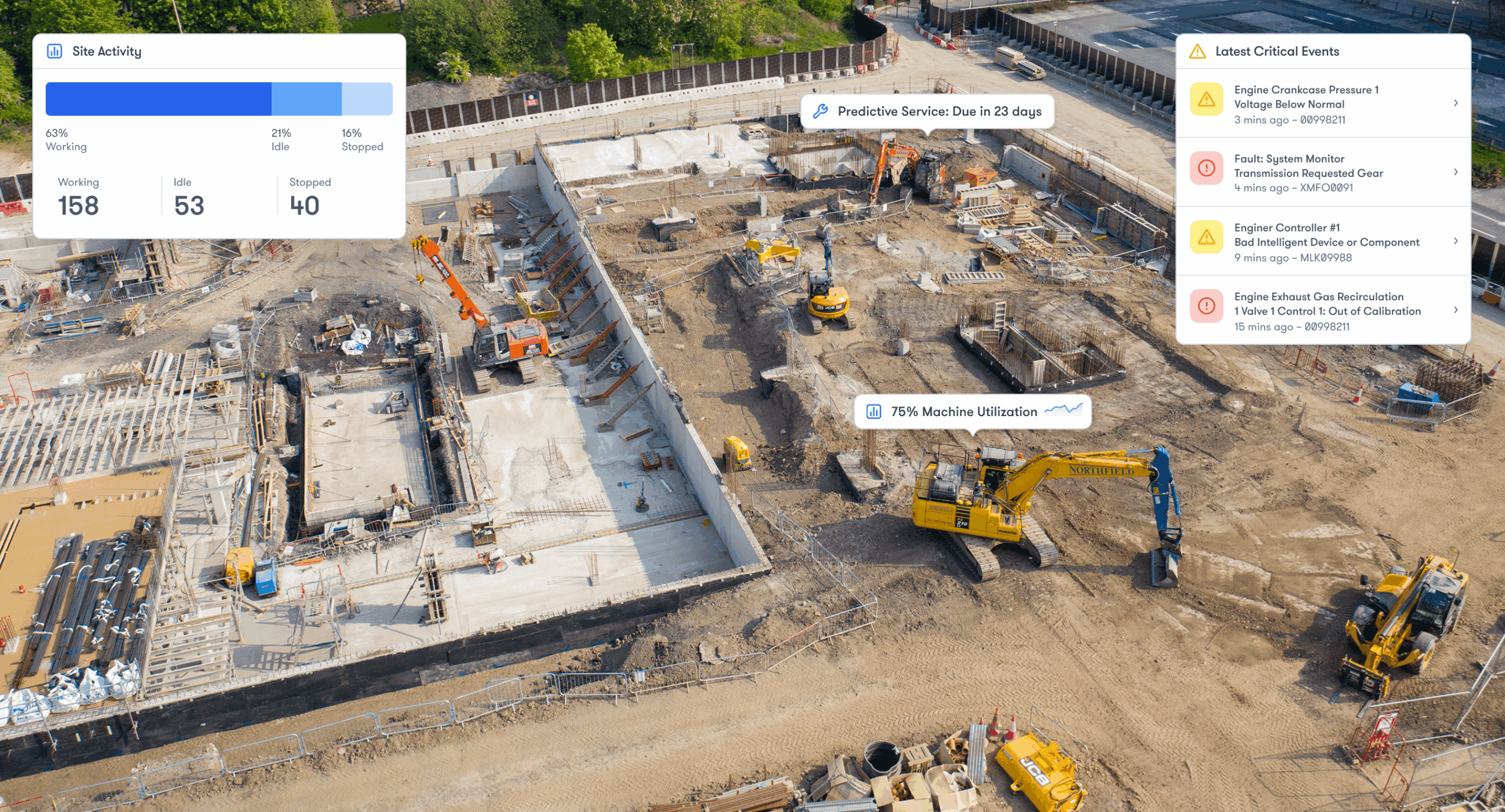

Real insight into every jobsite

Get clear visibility across fleets, tools, and crews. Eliminate blind spots, prevent delays, and keep jobsites moving on schedule.

Cut costs and save time where it counts

Know exactly where money slips away. From idle machines to unused rentals, mixed-fleet visibility exposes waste in real time so you get the most out of every asset.

Faster informed decisions

Live data shows when to rent, redeploy, or repair. Cut the guesswork to reduce delays and control costs.

Avoid unecessary relocation

Reduce fees on unused assets

Spot idle or underused equipment fast. Return rentals on time and put owned machines back to work.

Simplified crew coordination

Shared visibility means crews spend less time waiting, schedules stay tight, and overtime drops.

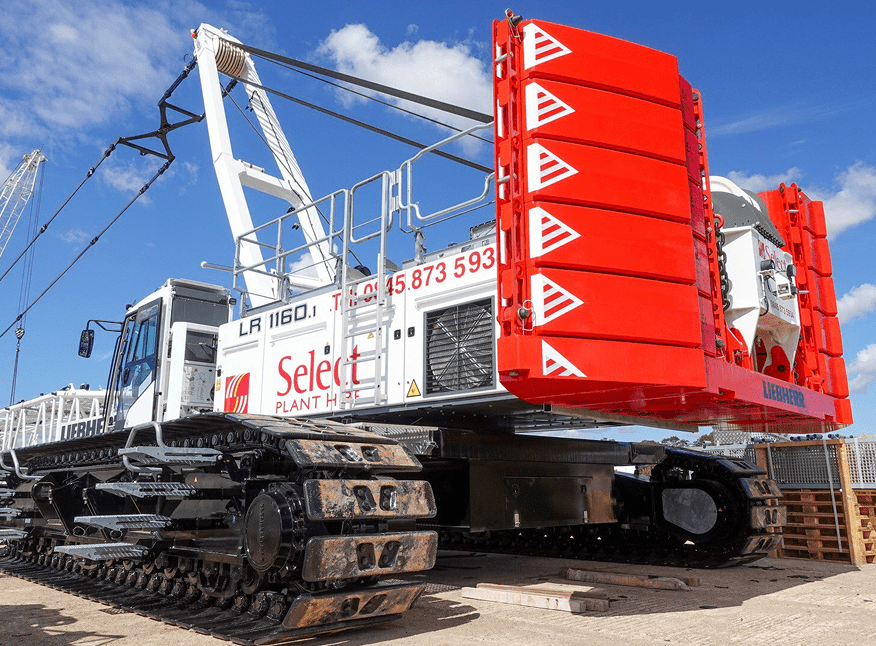

Trusted by leading equipment professionals

Join leading construction professionals and use Trackunit to gain visibility, cut downtime, and keep projects on track with data-driven jobsite insights.

How visibility and control support jobsites

With the right tools in place, jobsite leaders can spot problems early, make better decisions faster, and ensure work keeps moving without costly interruptions.

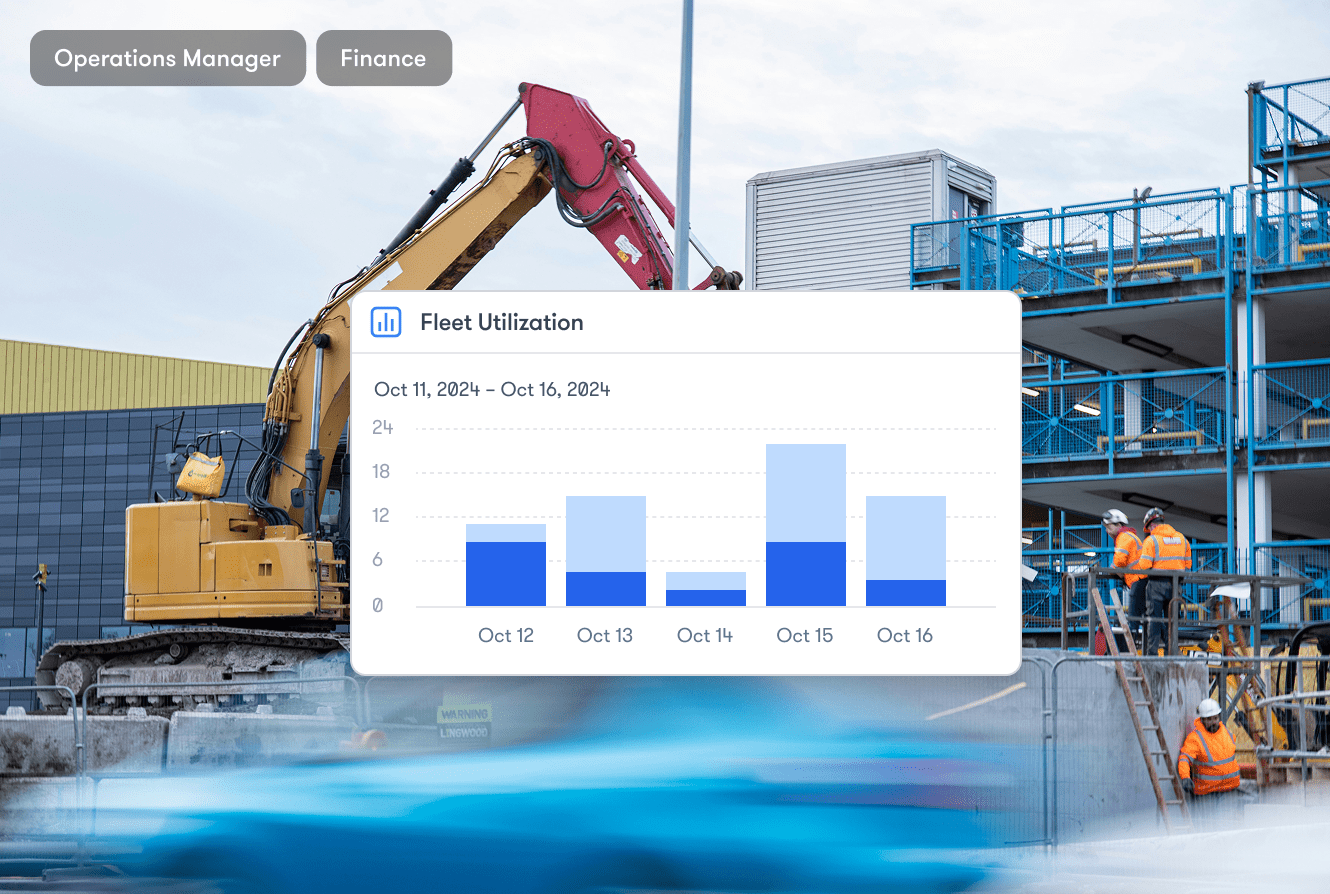

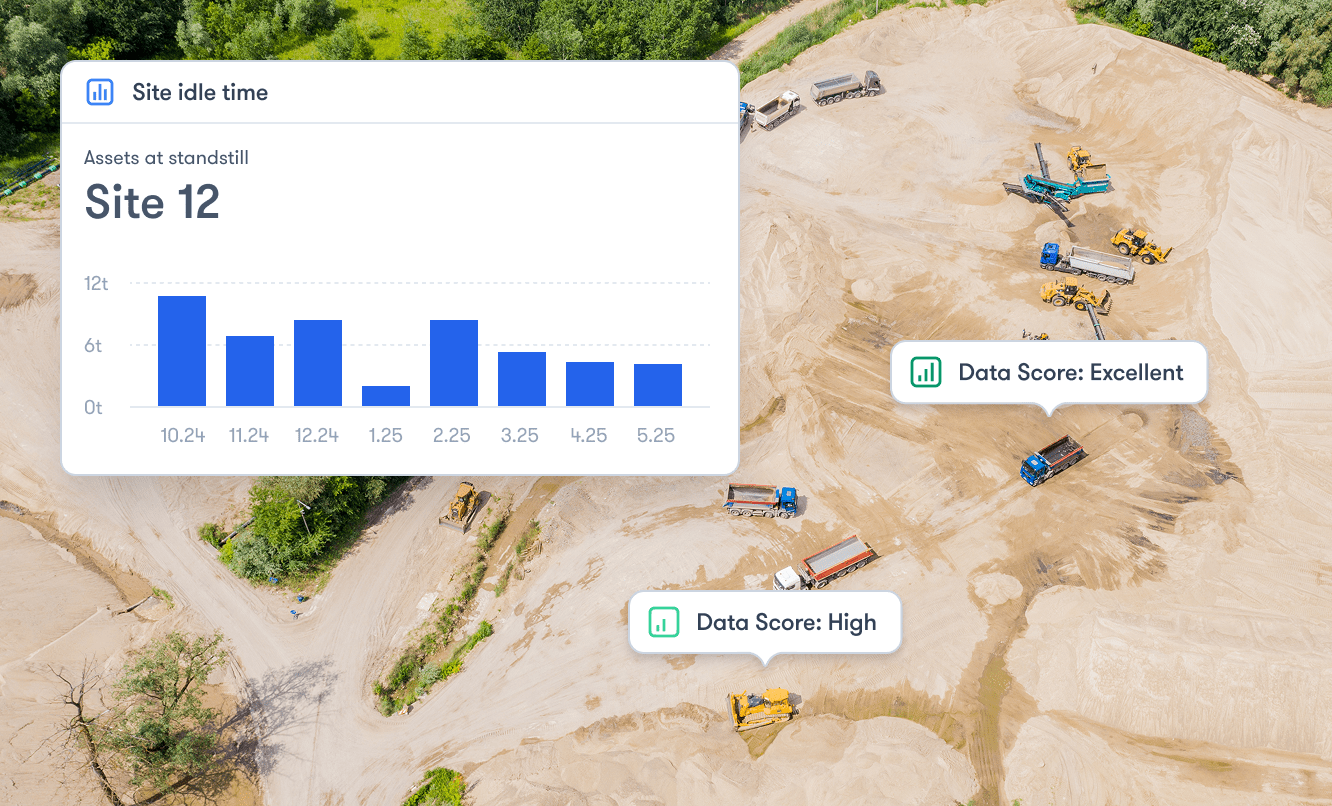

Reports

Utilization, idle time, and cost reports highlight inefficiencies and help direct resources where they are needed most.

Construction equipment can spend up to 30–40% of their time idling.

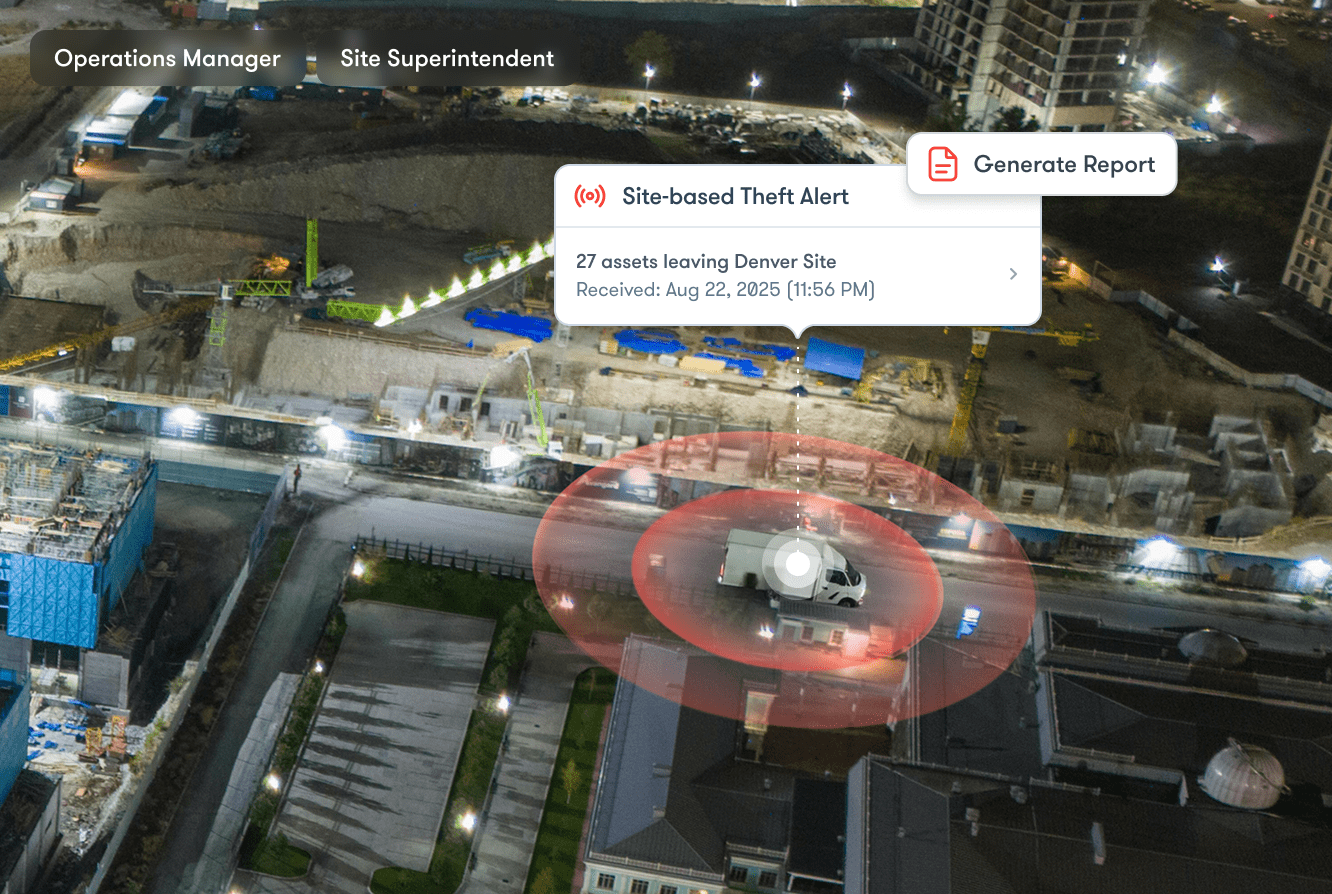

Alerts

Get real-time notifications on critical events like unauthorized use, fault codes, or downtime so you can act fast.

Save $10,000–$25,000 on each heavy equipment failure avoided.

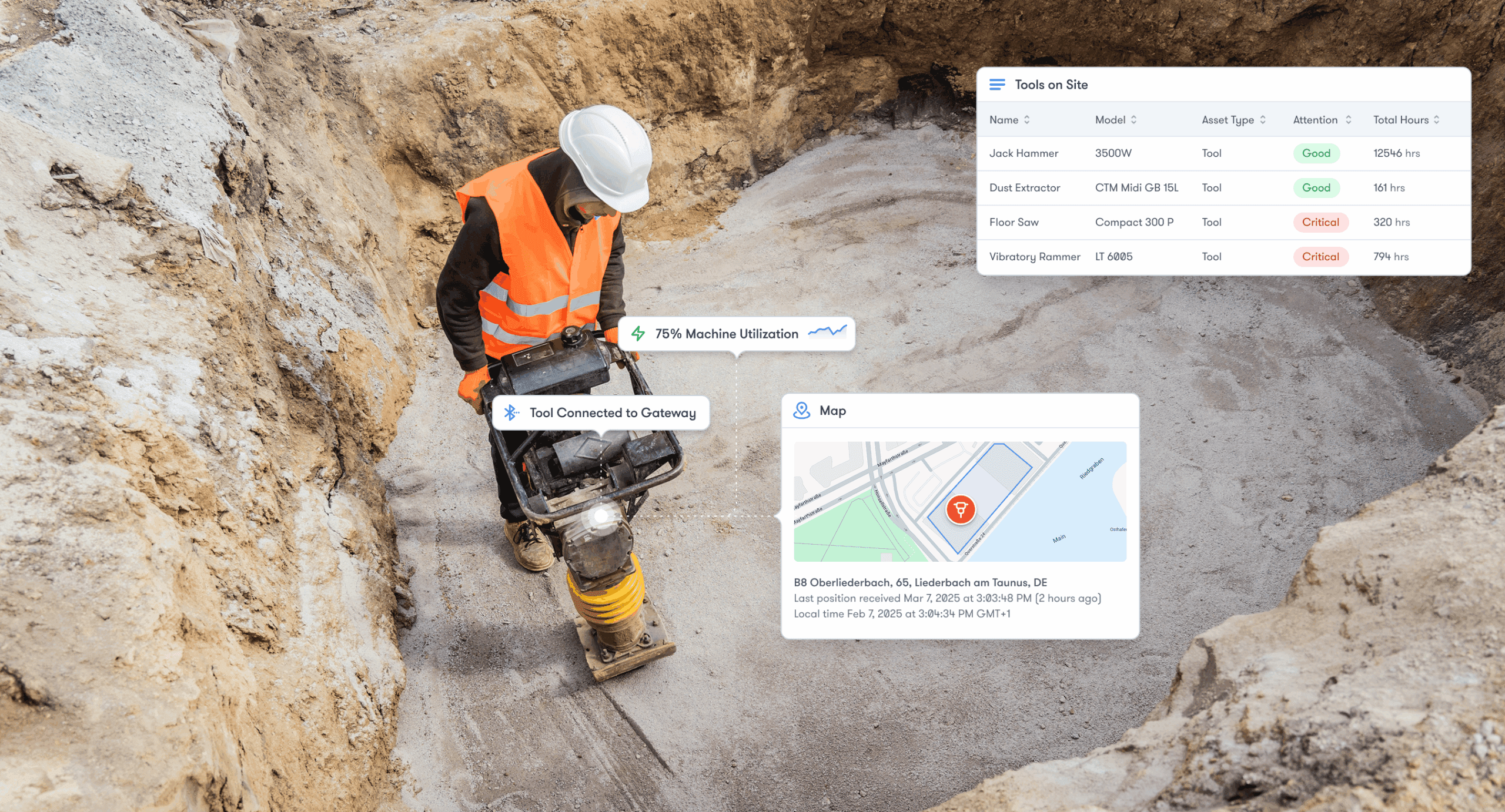

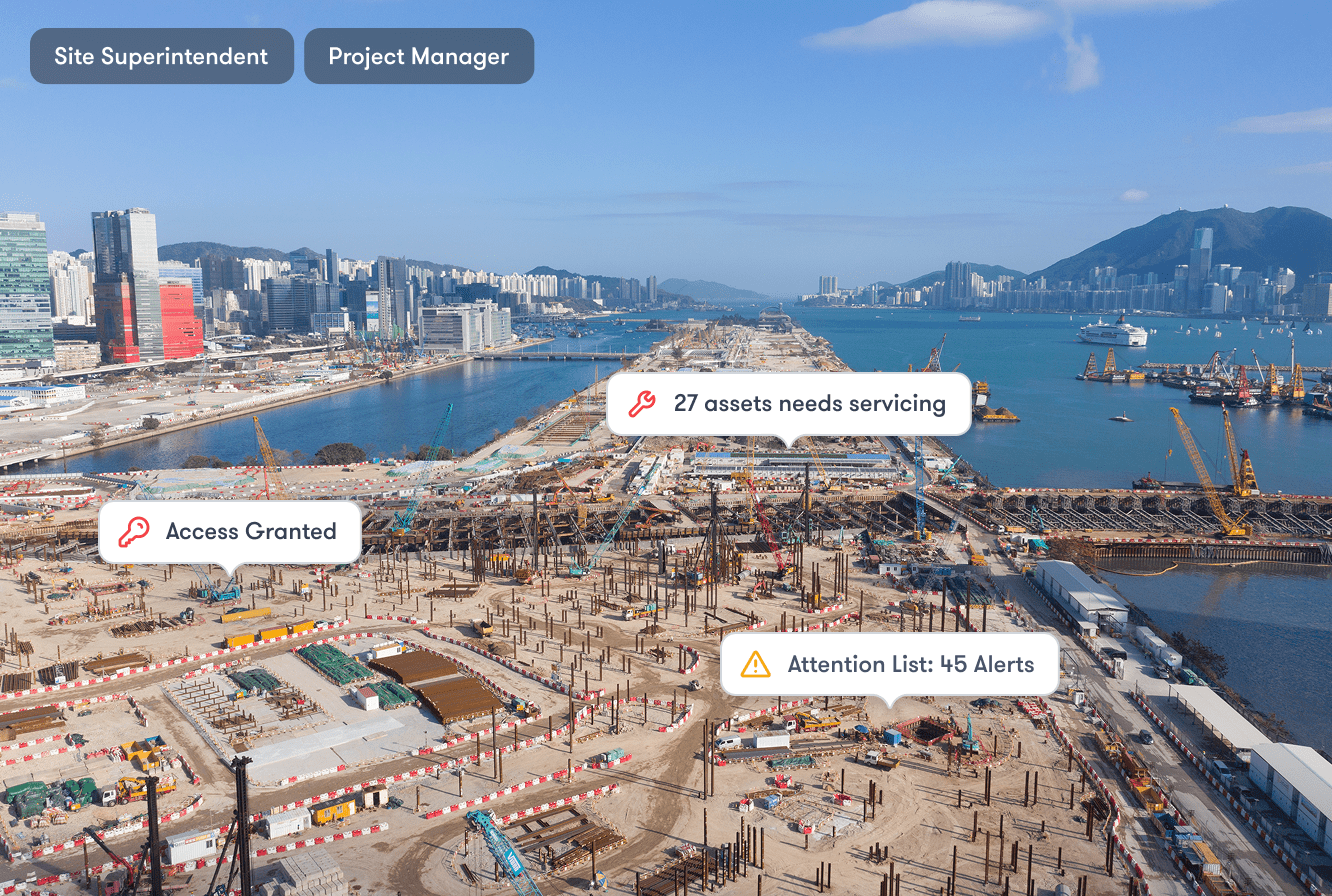

Network

Connect your own fleet with subcontractors, OEMs, and rental assets for one clear jobsite view.

24/7 continuous and automatic Bluetooth® connectivity coverage.

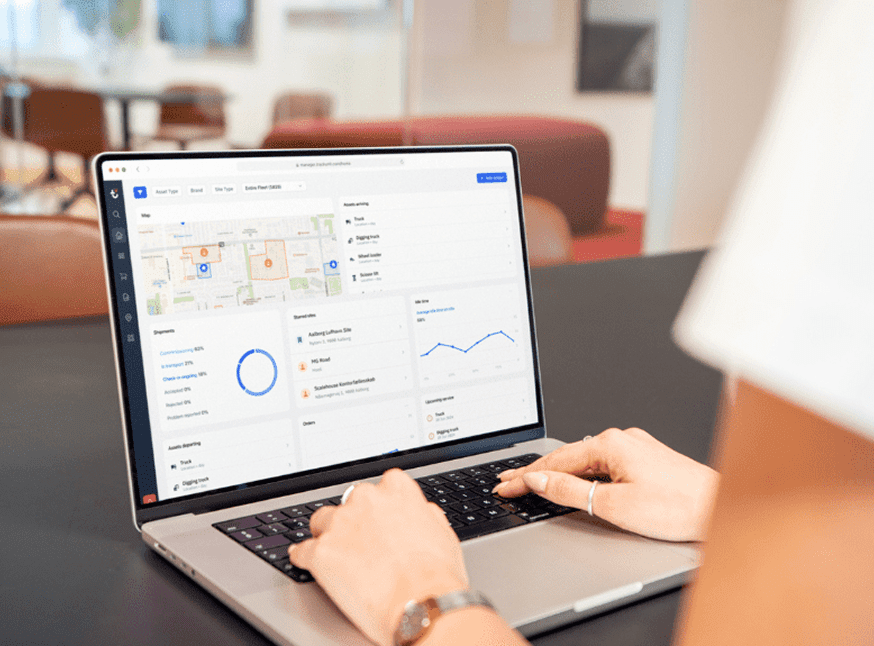

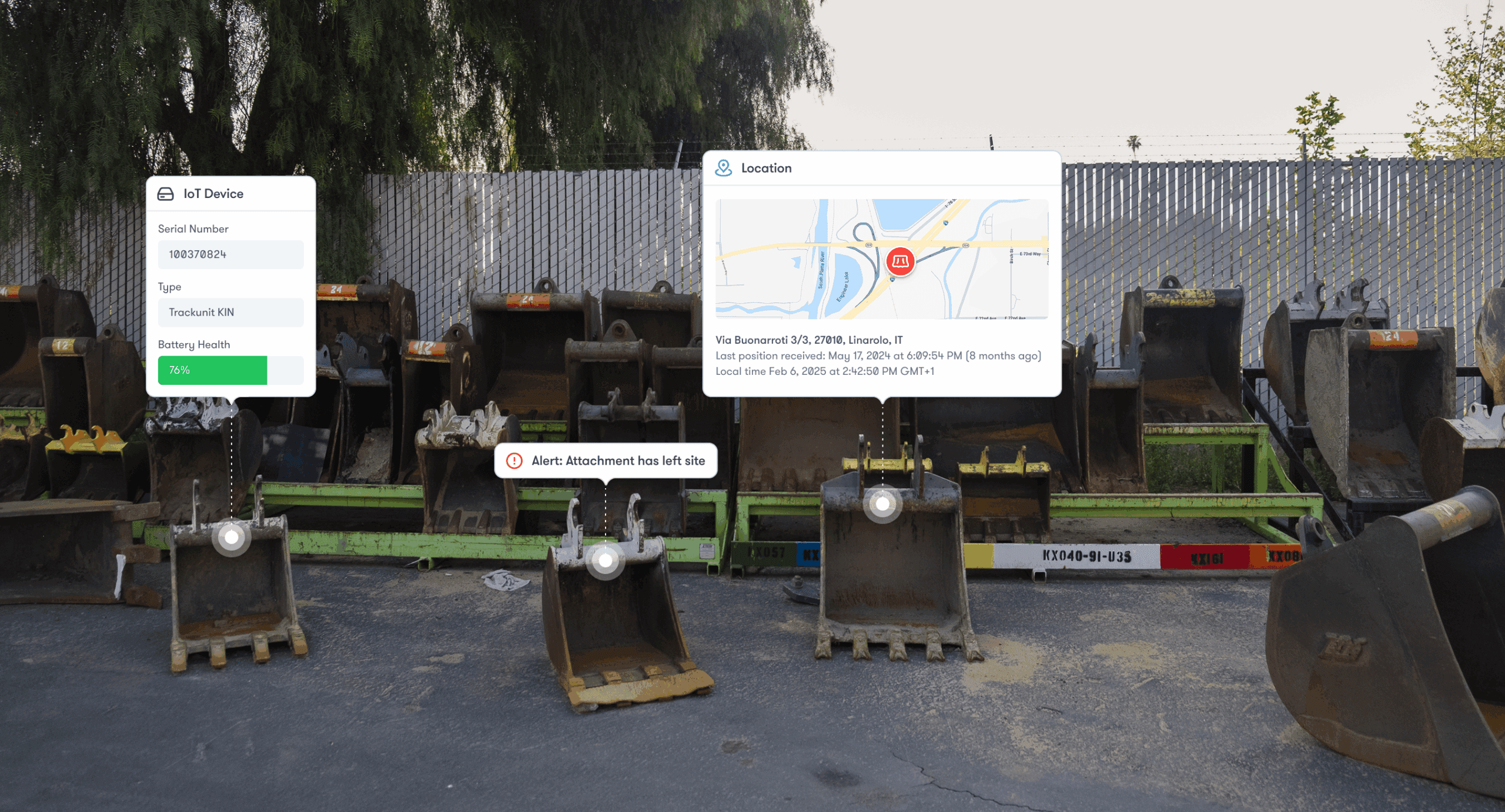

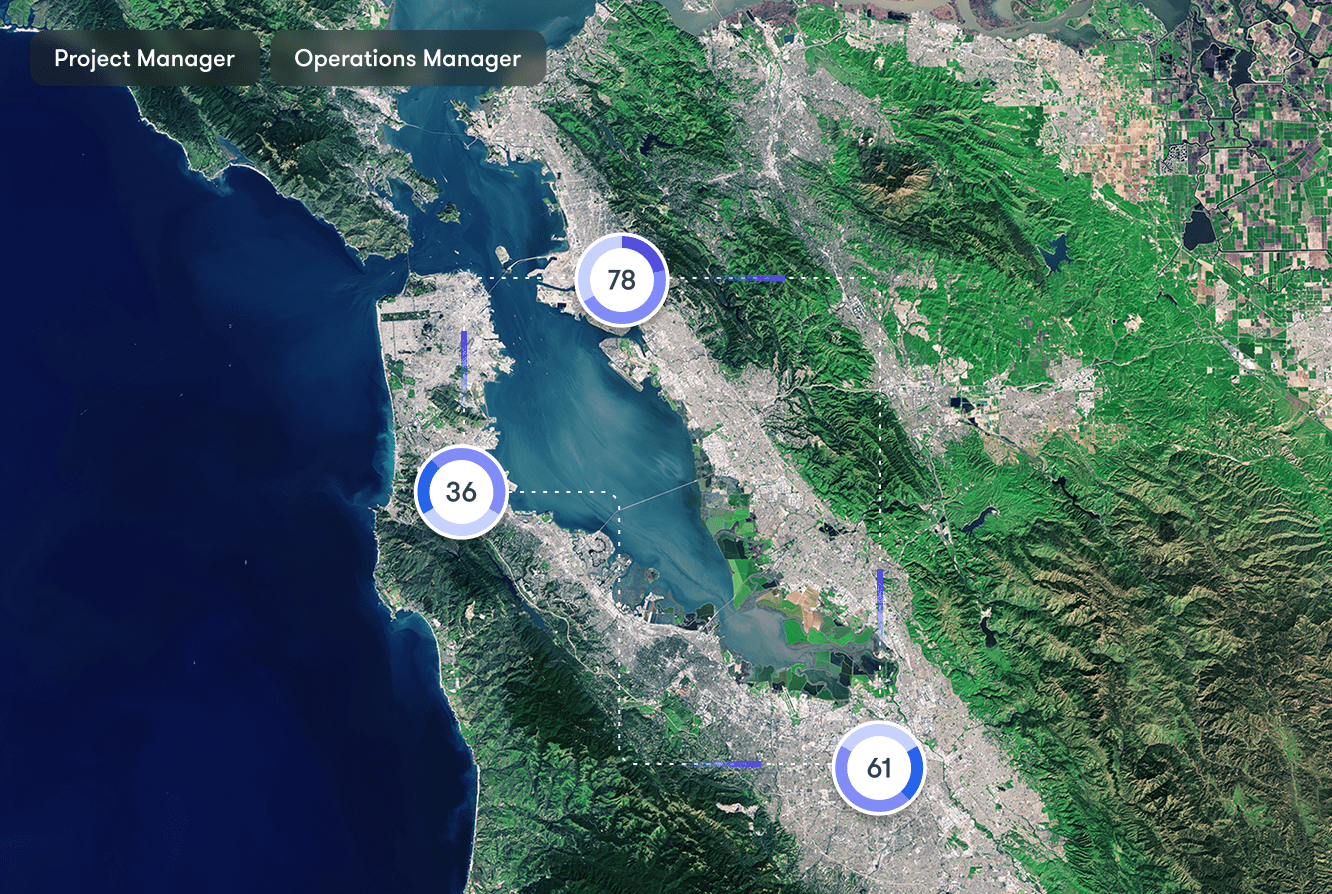

Map

Explore, identify, and address equipment needs with real-time status and location insights, in a streamlined, interactive view.

10% of an average workday is wasted searching for tools and equipment.

Map

Explore, identify, and address equipment needs with real-time status and location insights, in a streamlined, interactive view.

10% of an average workday is wasted searching for tools and equipment.

Utilization

Stop guessing and take control of costs, productivity, and performance with clear equipment usage information in hand.

8% increase in repeat business through improved customer utilization.

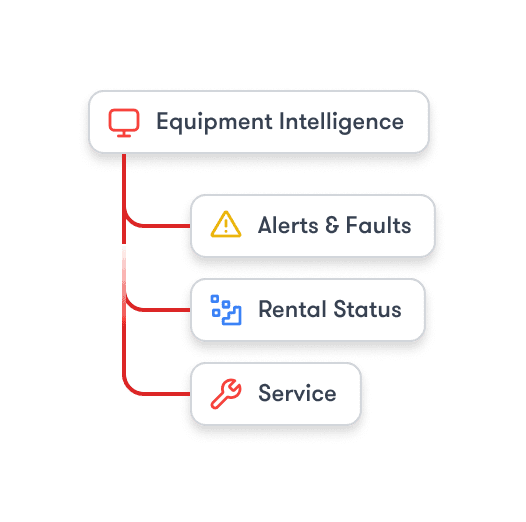

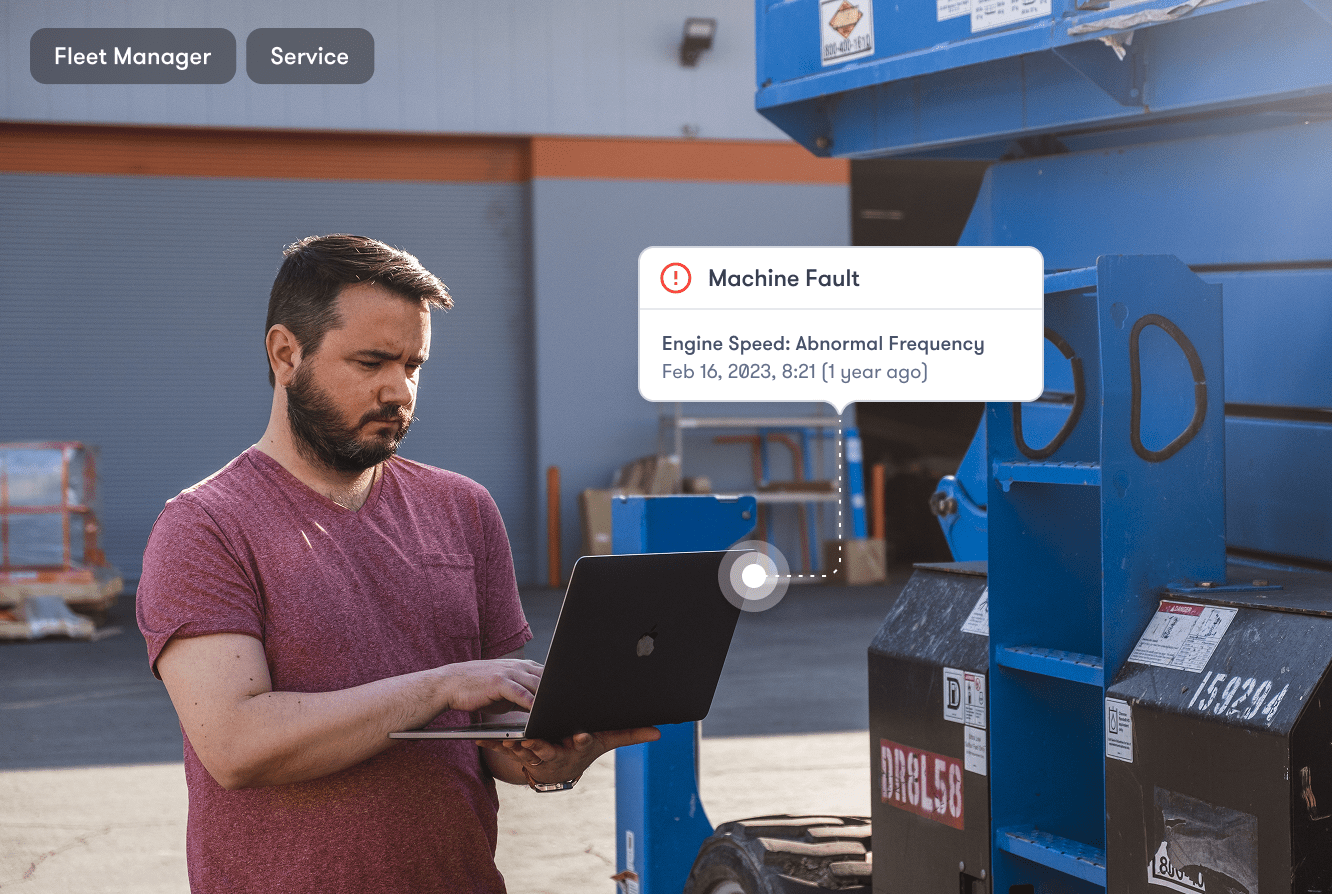

Health

Remotely diagnose the health of your equipment with detailed insights and take immediate action on potential break downs.

Reduce equipment downtime up to 50% with proactive insights.

Alerts

Proactively keep assets moving at all times by configuring notifications to bring critical machine conditions to the forefront.

Save $10,000–$25,000 on each heavy equipment failure avoided.

How connected equipment pays off the jobsite

Connected equipment turns wasted hours into stronger performance. Cut fuel costs with smarter utilization, prevent tool loss with real-time tracking, and reassign idle machines before they slow you down.

Fleet Management

Put data behind every equipment decision

Fleet management is knowing how often machines are actually used. It helps contractors cut idle time, reduce unnecessary rentals, and optimize the fleet around real demand, not assumptions.

Connected asset

Keep assets moving at the speed of your site

Access control, alerts, and idle-time insights help mixed fleets stay coordinated. Equipment gets flagged for reassignment before it becomes a bottleneck, keeping crews productive and projects on schedule.

Remote diagnostics

Don’t wait for an on-site breakdown to take action

Remote diagnostics and service tracking reduce unexpected failures and costly downtime. Trackunit’s Service Management solution helps repairs happen faster, easily track warranty coverage, and protect both uptime and budget.

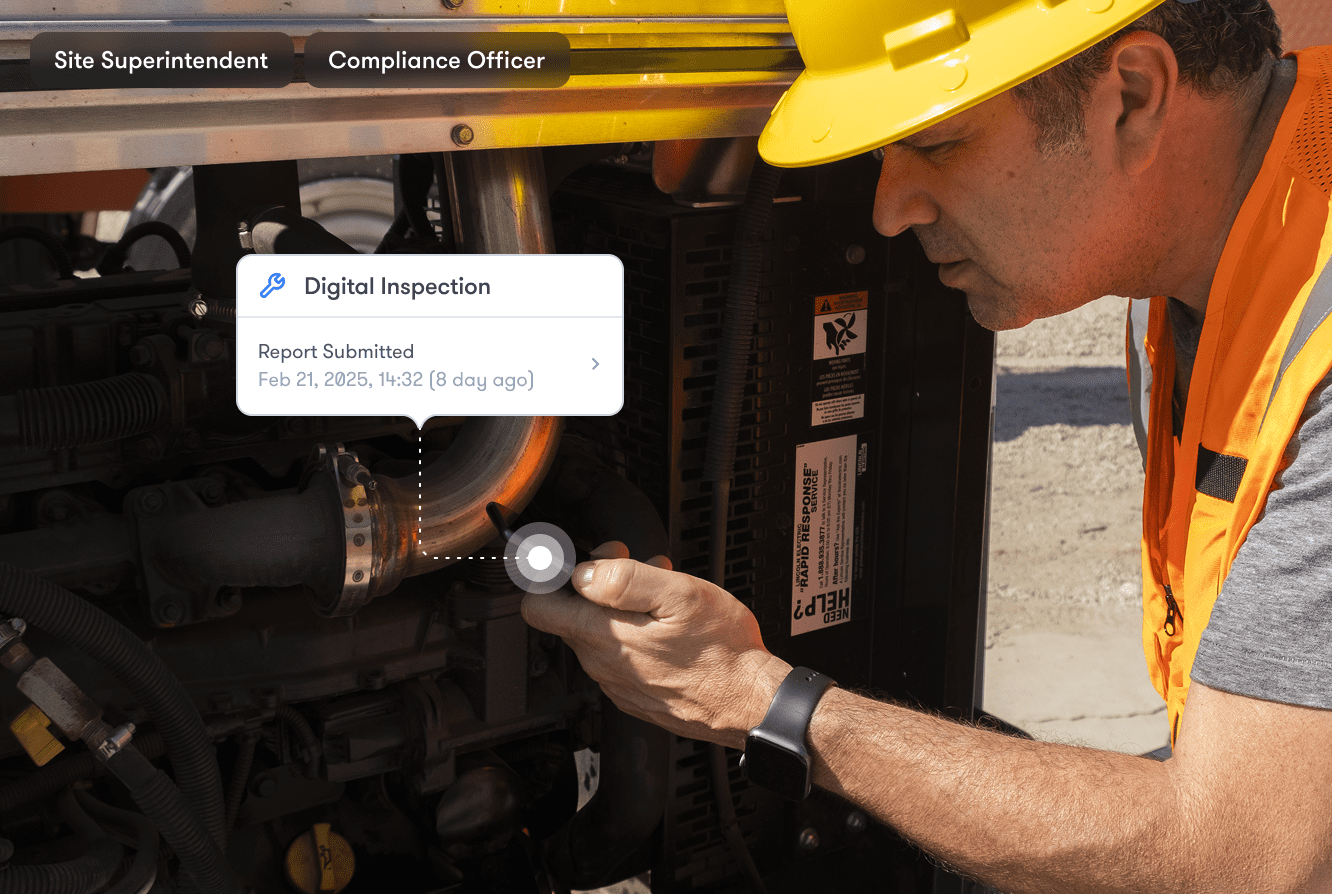

Unsafe equipment use

Build safer jobsites with fewer blind spots

Unsafe equipment use can be flagged in real time, giving teams the visibility they need to respond before an incident happens. Spot patterns, act faster, and protect crews without relying on paper checklists or delayed reports.

Construction equipment theft

Stop tool loss before it stops your crew

Construction equipment theft can stall crews, inflate costs, and cause delays. On sites with rotating teams and shared storage, need to know where tools are and who had them last helps prevent loss and avoid repeat spend.

Instant visibility

Put the right asset in the right place at the right time

When assets are spread across locations, underused machines often sit idle where they aren’t needed. Instant visibility across jobsites help reassign equipment based on actual demand, improving utilization and reducing the need for excess fleet.

The Impact of Insight

Reduce idle time by

20%

Rework accounts for approximately

22%

Save time locating assets

2,000+hrs

Use accurate real-time GPS location to save an average of 20 minutes each time you need to find an asset (at least twice per year per asset).

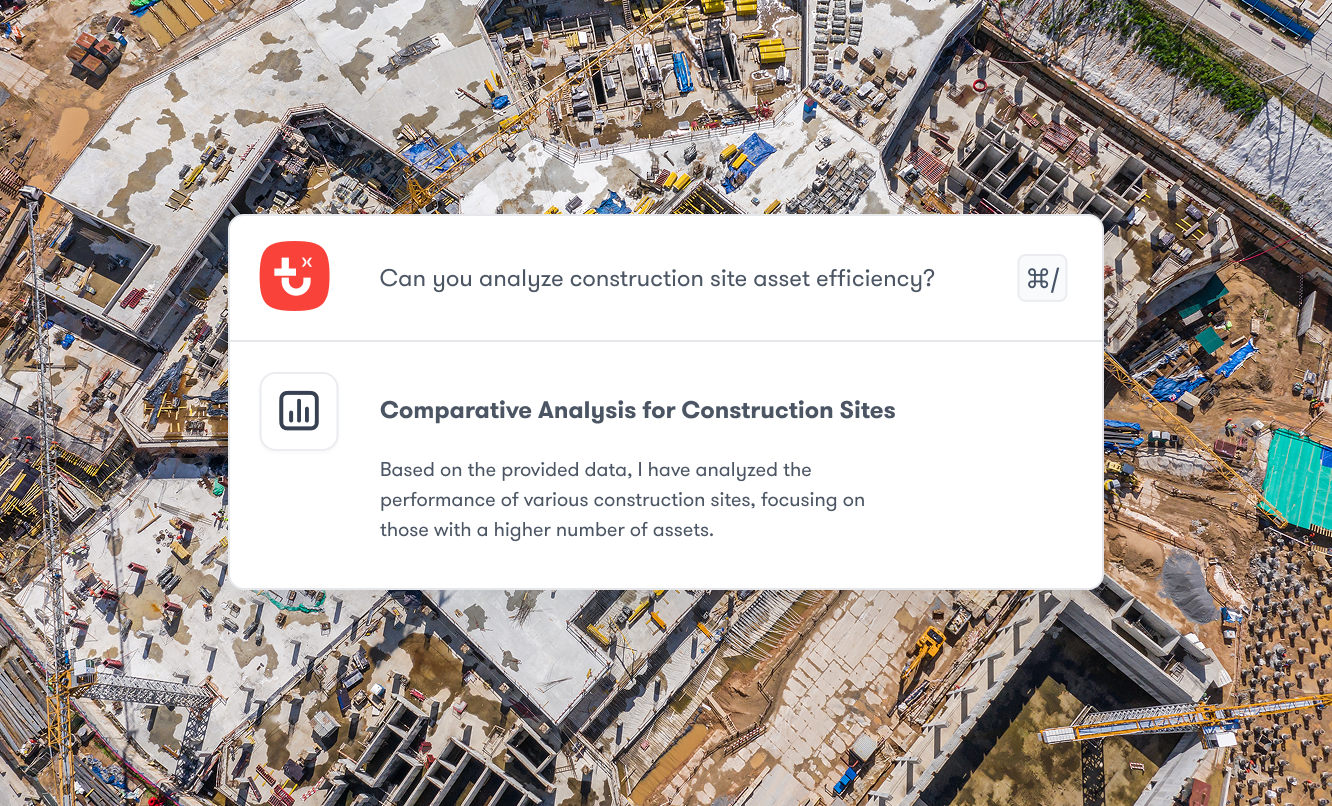

The impact of actionable insights

IrisX takes contractors beyond basic tracking. It transforms raw jobsite data into predictive insights, automates routine tasks, and highlights inefficiencies before they drain budgets. The result is measurable savings, higher performance, and stronger margins across every site.

AI Ready

Elevate your operational capabilities

IrisX automates routine tasks, spots risks before they hit your schedule, and turns jobsite data into clear actions that save time and money.

IrisX Blueprints

Optimize site idle times and emissions

For contractors, reducing idle time and emissions isn’t just good for the planet—it’s good for business. IrisX helps you track, analyze, and act on equipment data to cut fuel costs, meet compliance targets, and run more efficient job sites.

Gate who controls your machines

Keep jobsites safe and efficient by ensuring only trained and authorized operators can access equipment. Access Management helps reduce risks, prevent misuse, and maintains accountability with clear digital records.

Turn equipment data into decisions that keep projects on track

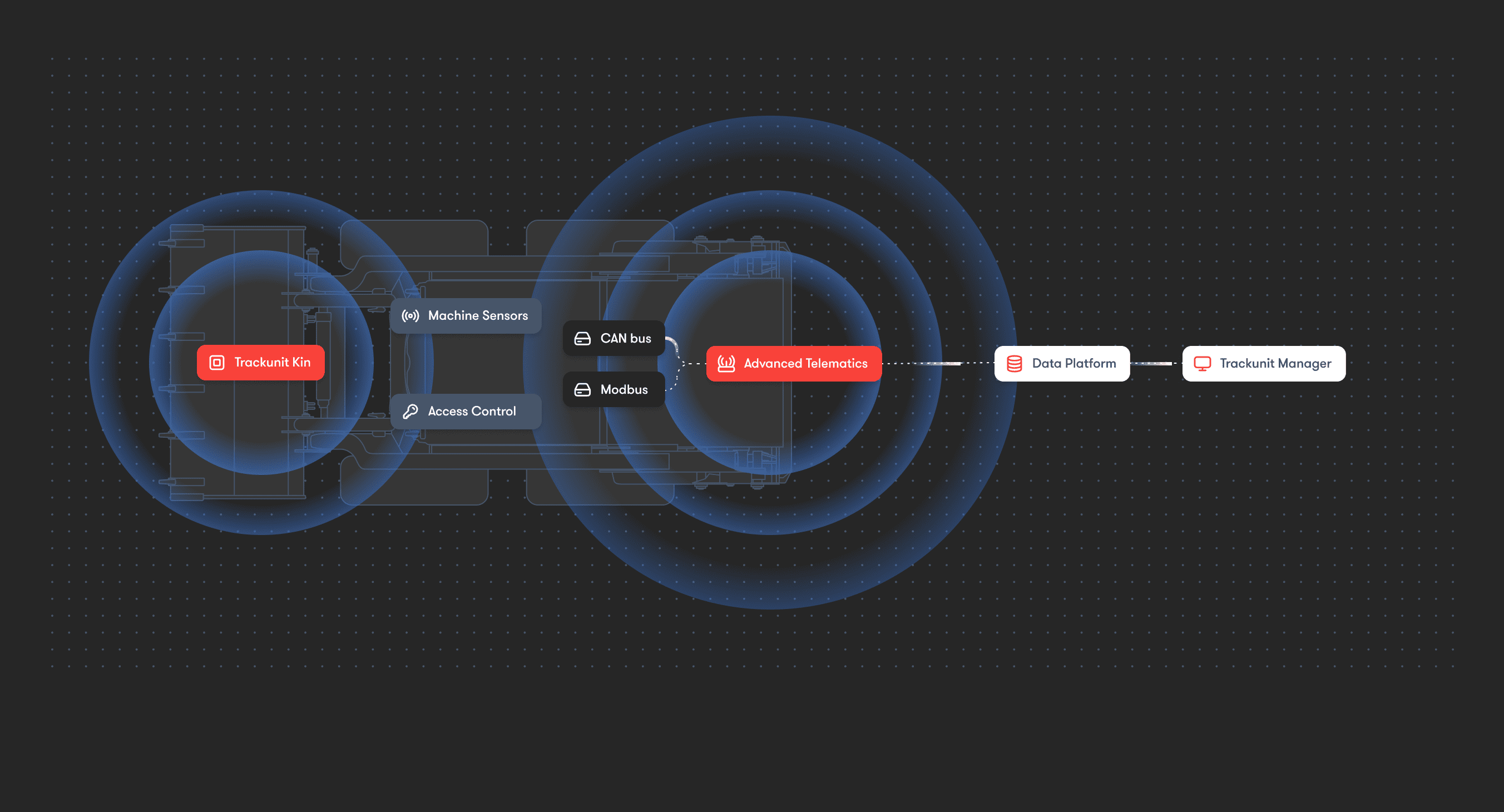

Telematics connects fleets, tools, and crews in one platform. This single source of truth turns fuel, maintenance, and utilization data into real cost control. It’s more than tracking machines; it’s about cutting downtime, reducing rentals, and keeping projects on schedule.

Software Features

Smart, easy-to-use tools that turn real-time data into better decisions.

Real-time GPS and equipment health

Utilization insights and reporting

Fuel usage and idle reporting

Preventative maintenance and service

Theft prevention and recovery

Smart alerts and automation

Geo-fencing and site-level intelligence

Digital Access Management

Fleet-wide emissions reporting

Role-based dashboards

And much more…

Connectivity

Reliable, jobsite-ready connections that work across your entire fleet.

Industry-leading construction IoT

Certified industrial-rated performance

Solutions for all equipment types

Global LTE-M 5G Roaming

Edge, OTA, and AI smart services

100+ plug and play OEM data feeds

Autonomous Bluetooth network

Secure, governed, scalable, and private

API access for custom workflows

Centralized cloud platform integration

And much more…

Services & Support

From onboarding to full optimization or customization, we’re with you all the way.

SLA-backed uptime and reliability

Multi-channel customer support

Customer success program

Multilingual platform & Help Center

OEM and retrofit install programs

Public, interactive product roadmap

Flexible fleet and asset plans

Marketplace App integrations

Developer Hub and SDK

Consulting & hands-on workshops

And much more…

Request a consultation

Get hands on with the solutions that can empower your digital journey. Let’s connect and find the right time and place for a demo to explore your connectivity potential.

How leading contractors use telematics today

Explore examples and practical guidance on how telematics is supporting jobsites today. Here’s how contractors are cutting downtime, improving visibility, and protecting margins.