Bane Machinery is a trusted supplier in the United States, delivering reliable machines and on-demand service. Founded in 1963 by George P. Bane it remains family-owned with that ground roots touch bolstered by its three branches across the state of Texas.

As their fleet expanded, so did the complexity of tracking utilization and maintenance across multiple manufacturers, until they leveraged to Trackunit to help them bring it all together.

“Before Trackunit, we were managing hours across spreadsheets,” says Brandon Bane, Rental and Sales Coordinator at Bane Machinery. “Now, everything’s visible in one place.”

Bane’s service team was juggling between manufacturer portals, manually logging machine hours, and updating maintenance schedules in sprawling spreadsheets. The process was time-consuming and left room for missed services and inconsistent data across brands.

“It worked, but it wasn’t great,” adds Bane. “Each OEM had its own system, so our team had to log into multiple platforms just to get a complete picture.”

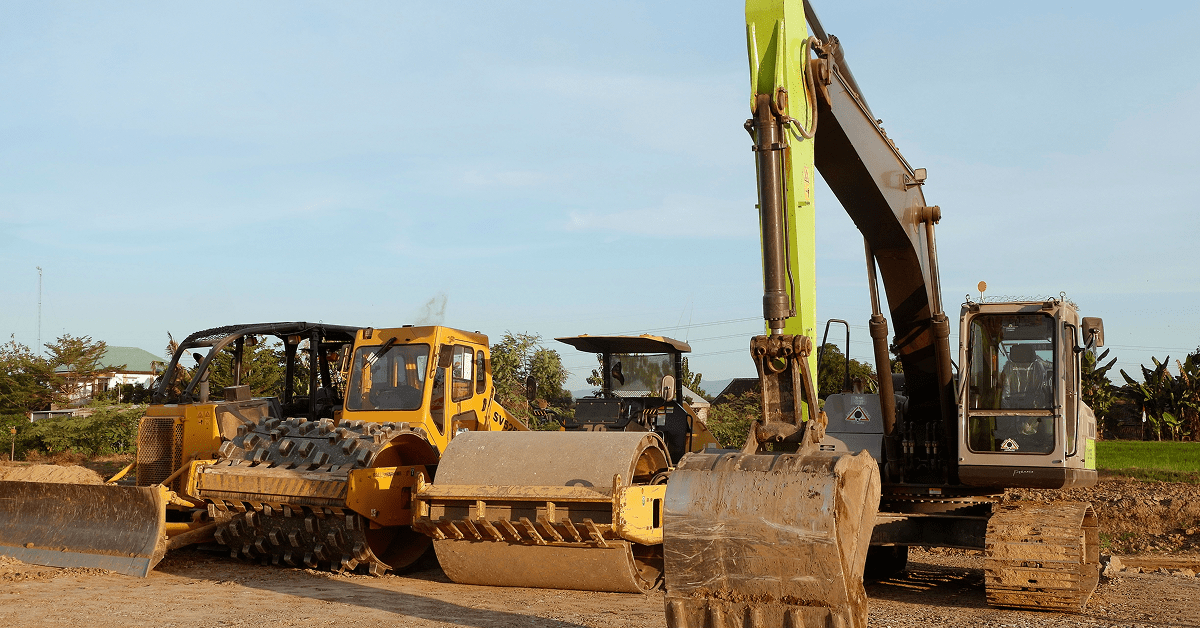

Given that this was also across a wide range of equipment including excavators, wheel loaders, motor graders, dozers and compactors, the process was time consuming and left room for missed services and inconsistent data across brands.

With Trackunit, Bane was able to consolidate all manufacturer feeds into one unified platform. The team gained real-time visibility into machine status, service intervals, and usage data across every brand in their mixed fleet.

That single source of truth allowed the service department to move from reactive to proactive. The switch reduced manual effort, improved accuracy, and gave them time to focus on keeping the fleet running, not just tracking it.

“It’s made a huge difference for our service operations,” says Bane.

The benefits for Bane Machinery and its customers included the following:

Those improvements also freed up capacity. What once required multiple staff members now takes a single office team member, enabling Bane to expand its lube truck operations and focus on higher-value service work.

Their experience shows how connecting data through Trackunit Manager doesn’t just simplify operations, it empowers teams to grow confidently.