Turn utilization insight into profits and productivity

Bring all your utilization equipment data into one view. Turn fragmented insights into clear actions that reduce idle time, right-size your fleet, and increase productivity across your operations.

Gain visibility on utilization to improve your fleet performance

Eliminate guesswork and take control of costs and performance. Trackunit’s connected platform unites your utilization data, showing exactly how each machine is used and turning insights into measurable results.

Increase utilization visibility

End the hunt for equipment data, spot idle assets instantly and make confident fleet decisions without guesswork.

Realize savings

Cut rental and ownership costs by spotting underused machines early. Sell or reallocate assets based on data.

Enhance equipment life span

Capture revenue from machines working beyond contract terms and bill accurately for every hour of use.

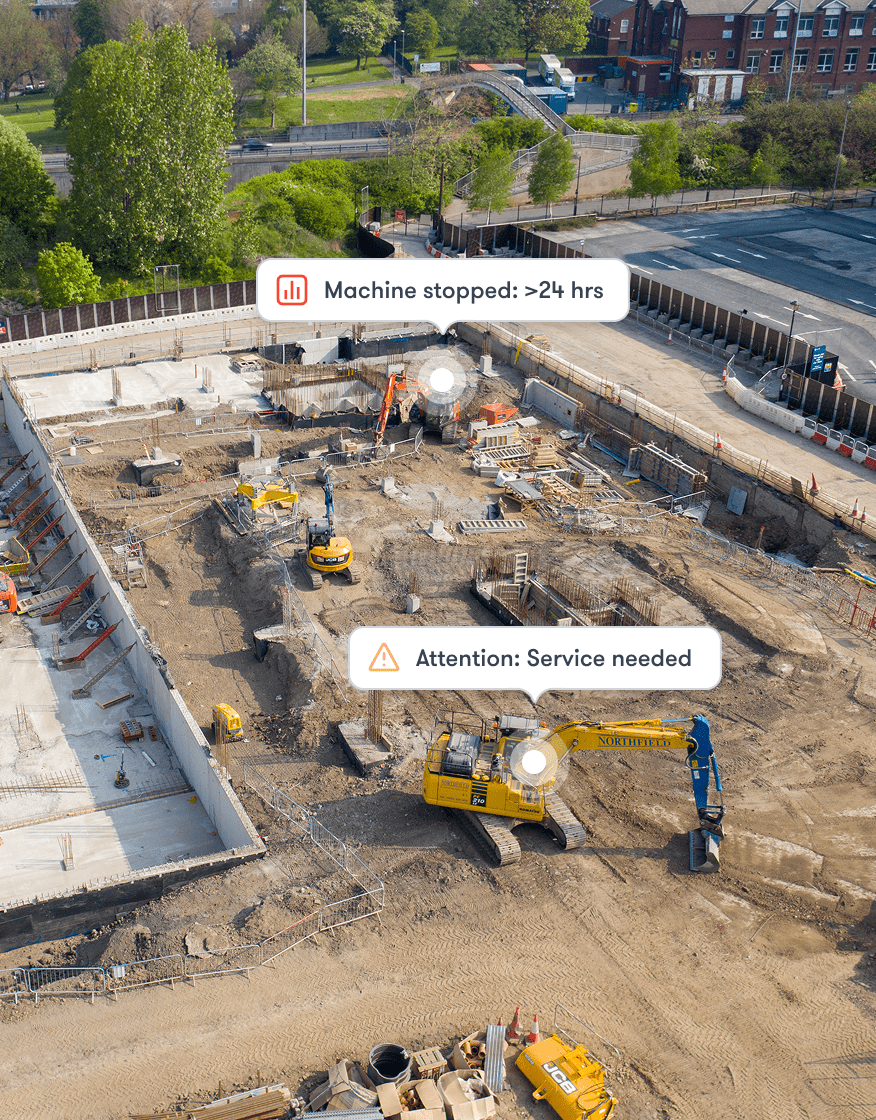

Maximize uptime

Turn idle time into measurable savings by identifying underutilized machines and optimizing deployment.

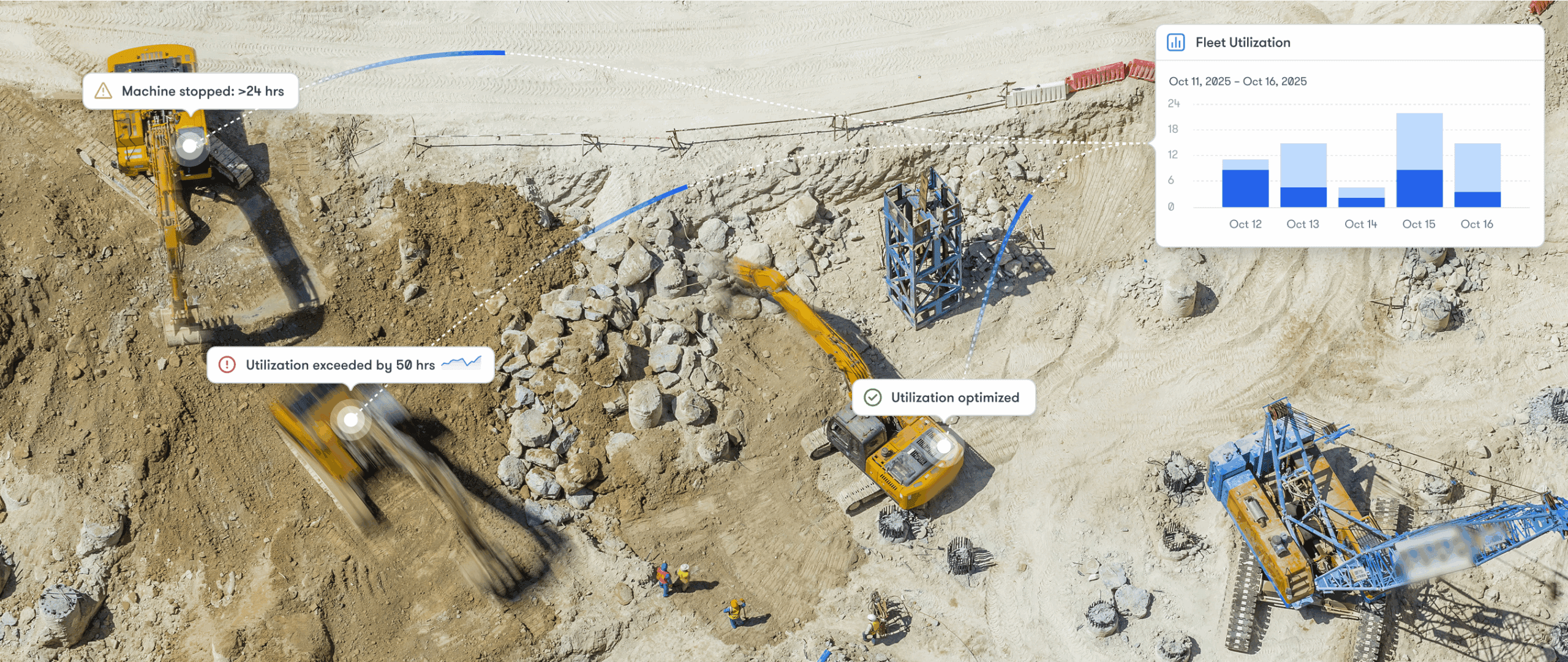

Solve every utilization challenge with connected insights

From over-utilization to unbilled hours, Trackunit gives every stakeholder the visibility they need to act fast and improve fleet efficiency.

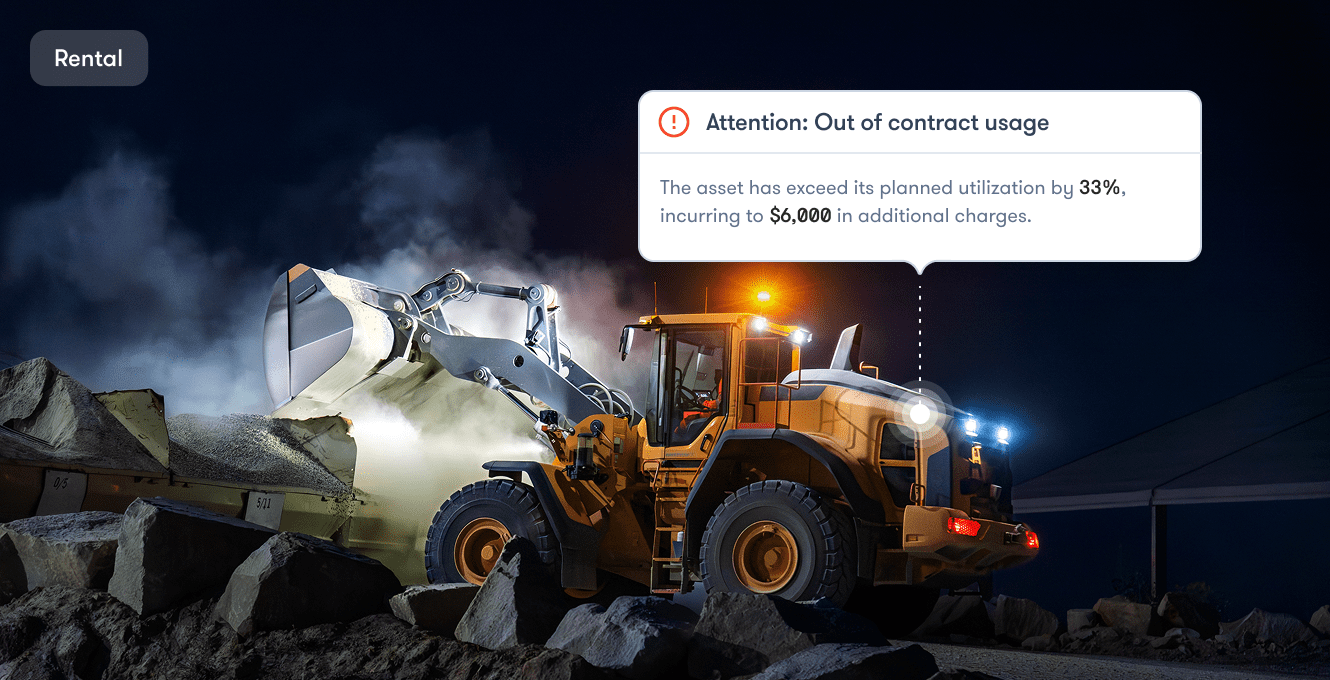

Out of contract equipment use

Close the gap between contract status and utilization by capturing every billable hour with detailed utilization reports ensuring no machine use goes unbilled.

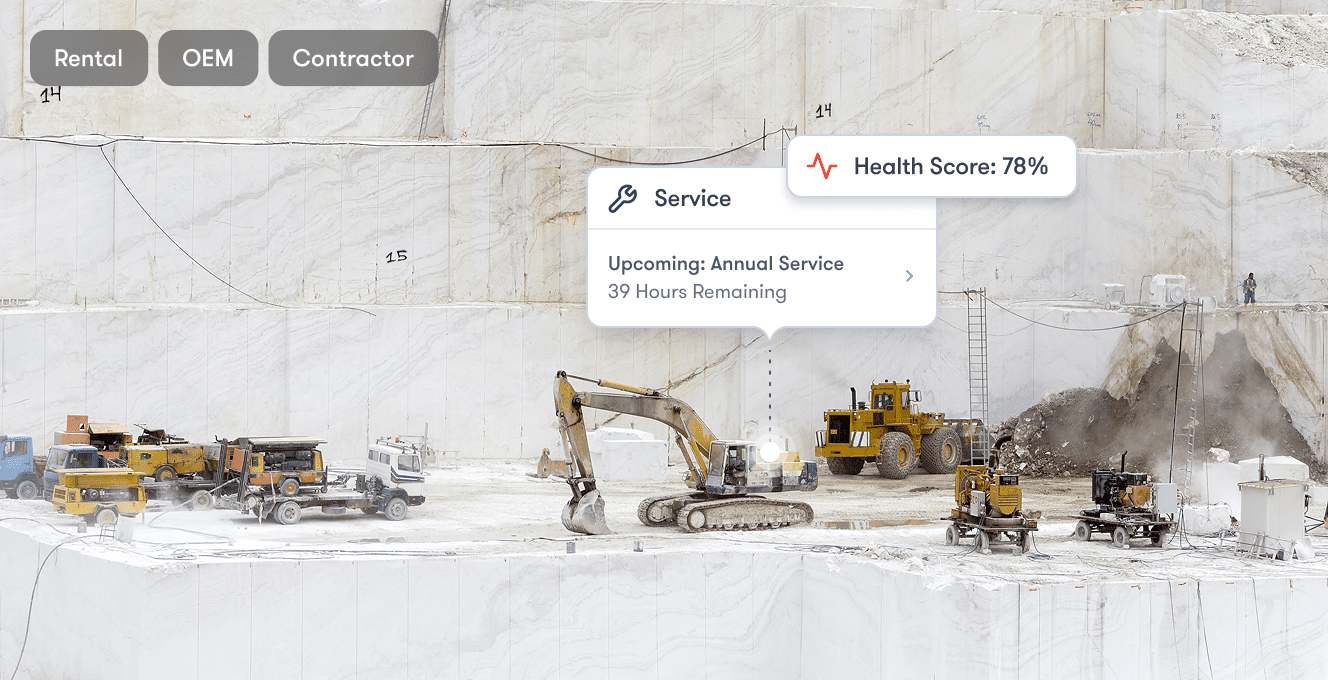

Optimize equipment usage

Prevent costly breakdowns by tracking over-utilization and scheduling proactive maintenance before downtime hits.

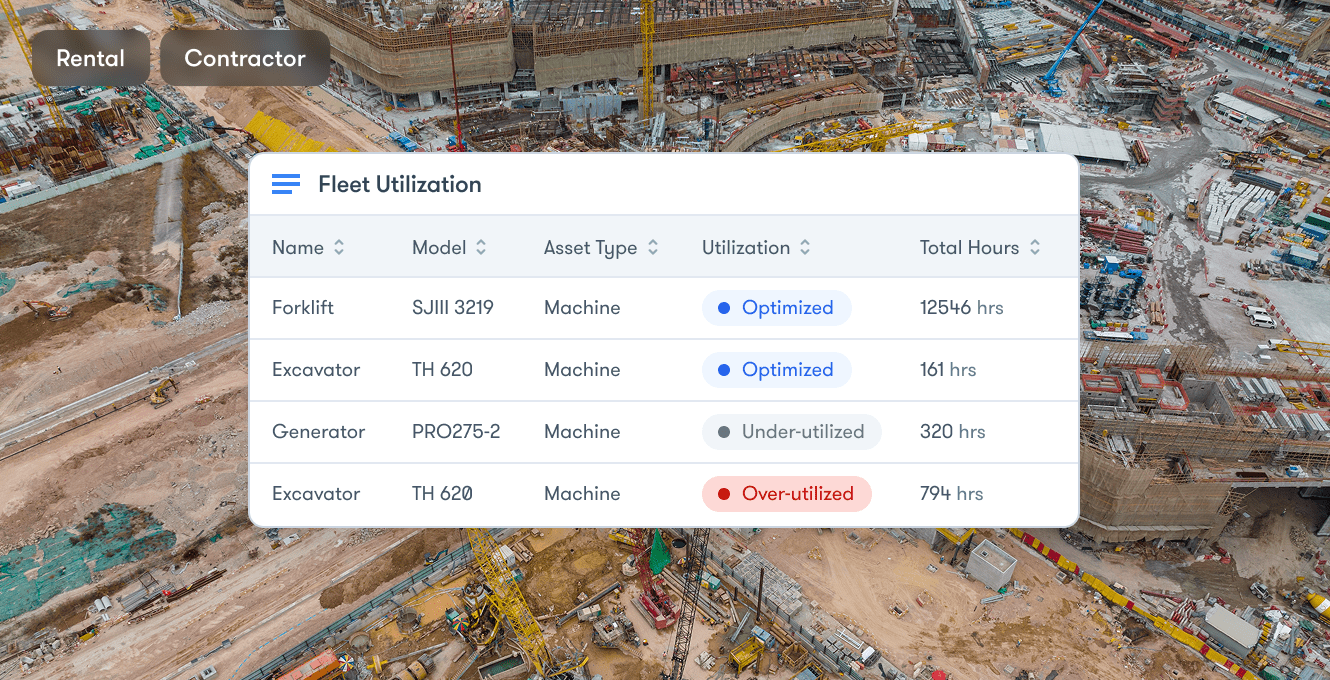

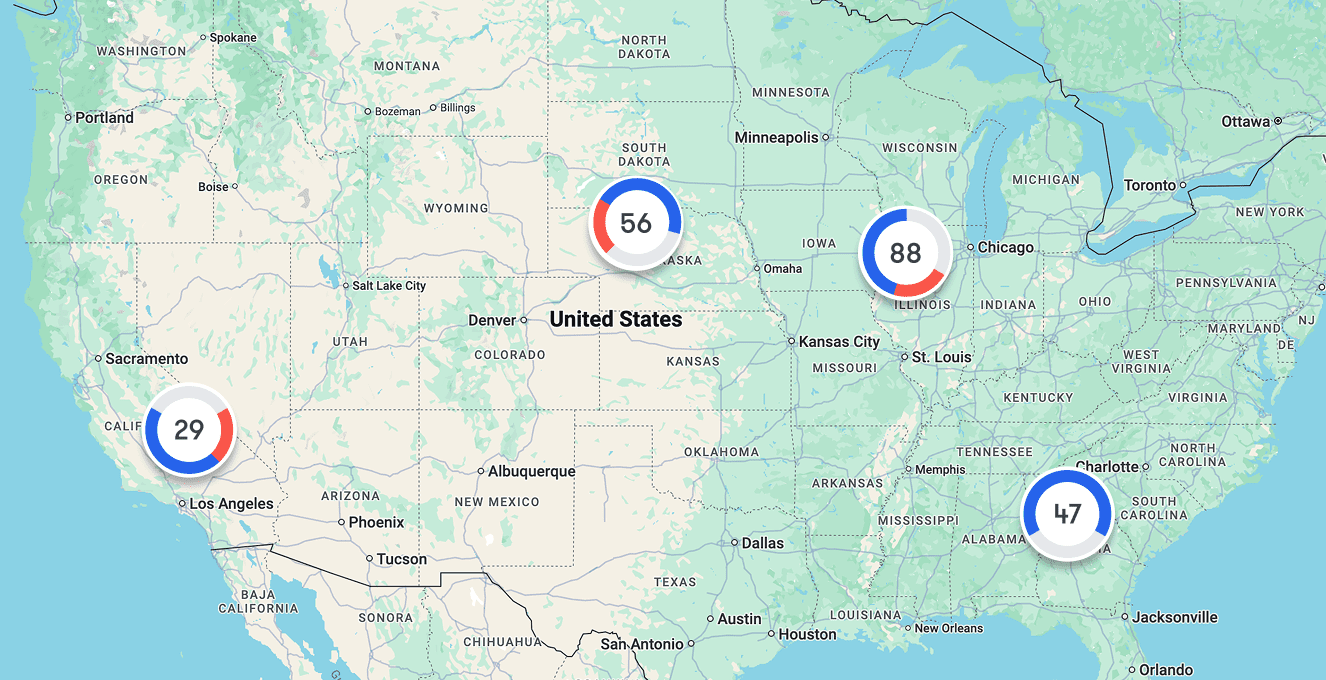

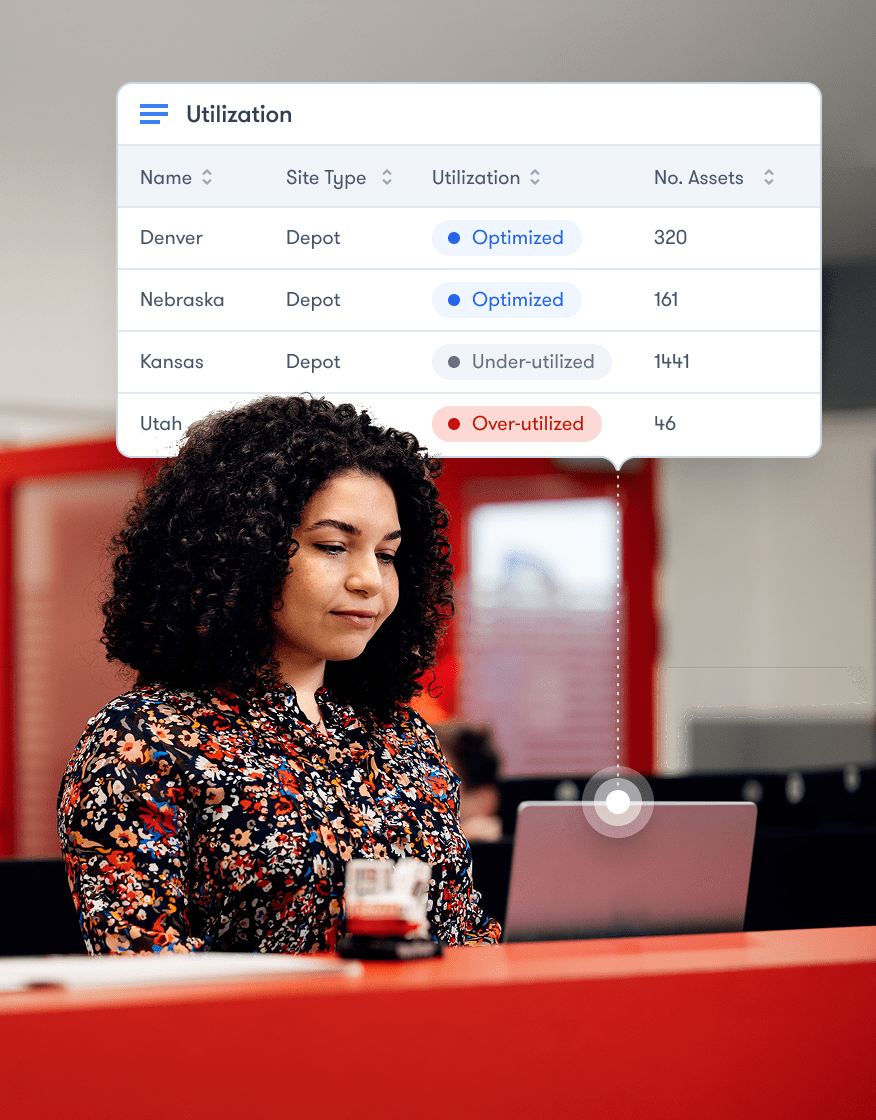

Identify over and under utilization

Compare fleet utilization across machine types to identify high or low performing assets and ensure your fleet matches your project load.

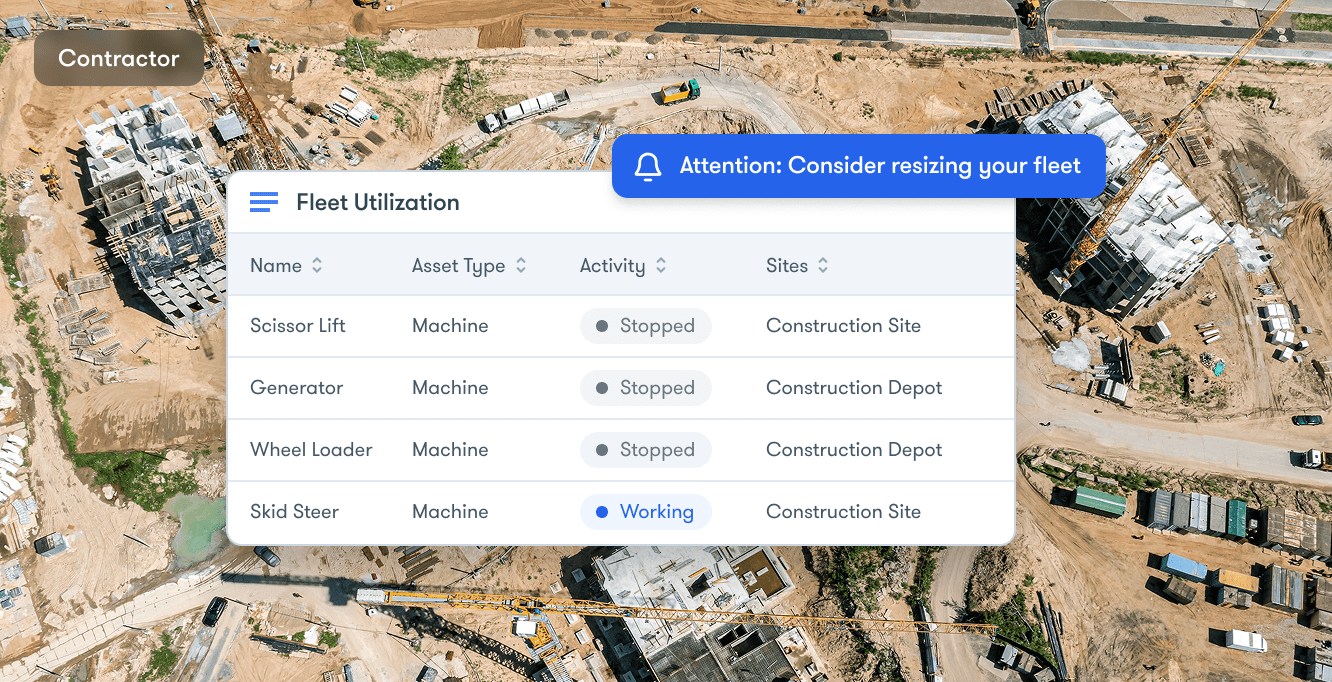

Relocated idle equipment

Quickly locate idle assets and redeploy them where they’re needed most, reducing transport costs and maximizing machine use.

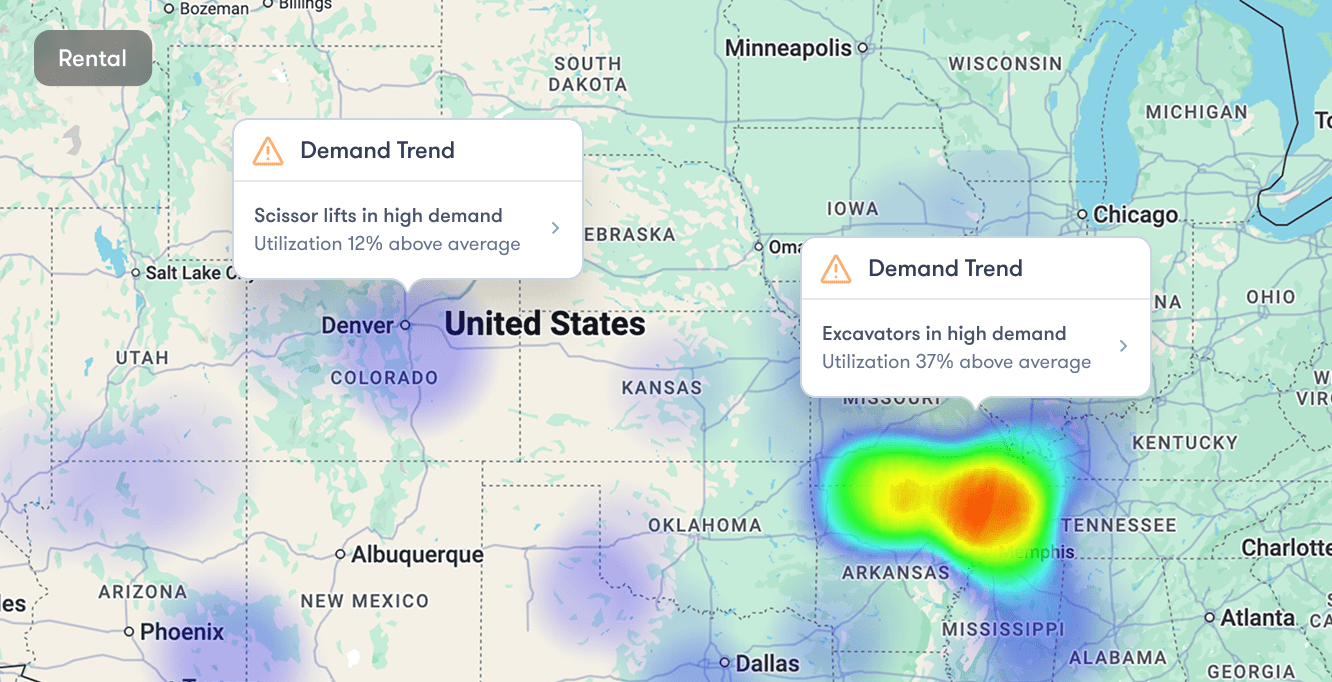

Spot upsell opportunities

Use utilization data to ensure you have high-demand equipment ready when customers need it, matching customer demand and maximizing revenue.

Monitor rented equipment

Identify underused rented equipment and adjust your rental agreements based on actual usage patterns to lower costs.

Join the best in business

Trusted by leading OEMs, rental companies, contractors, and partners to unlock the full value of their fleets and equipment.

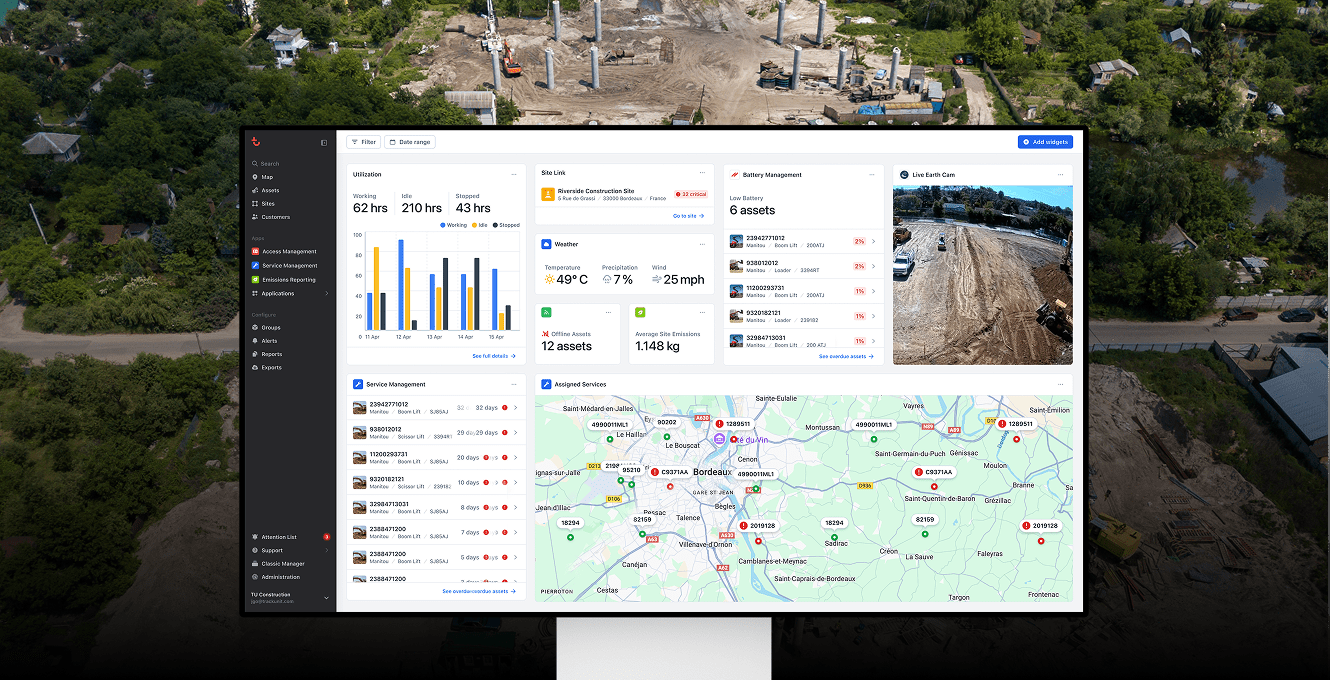

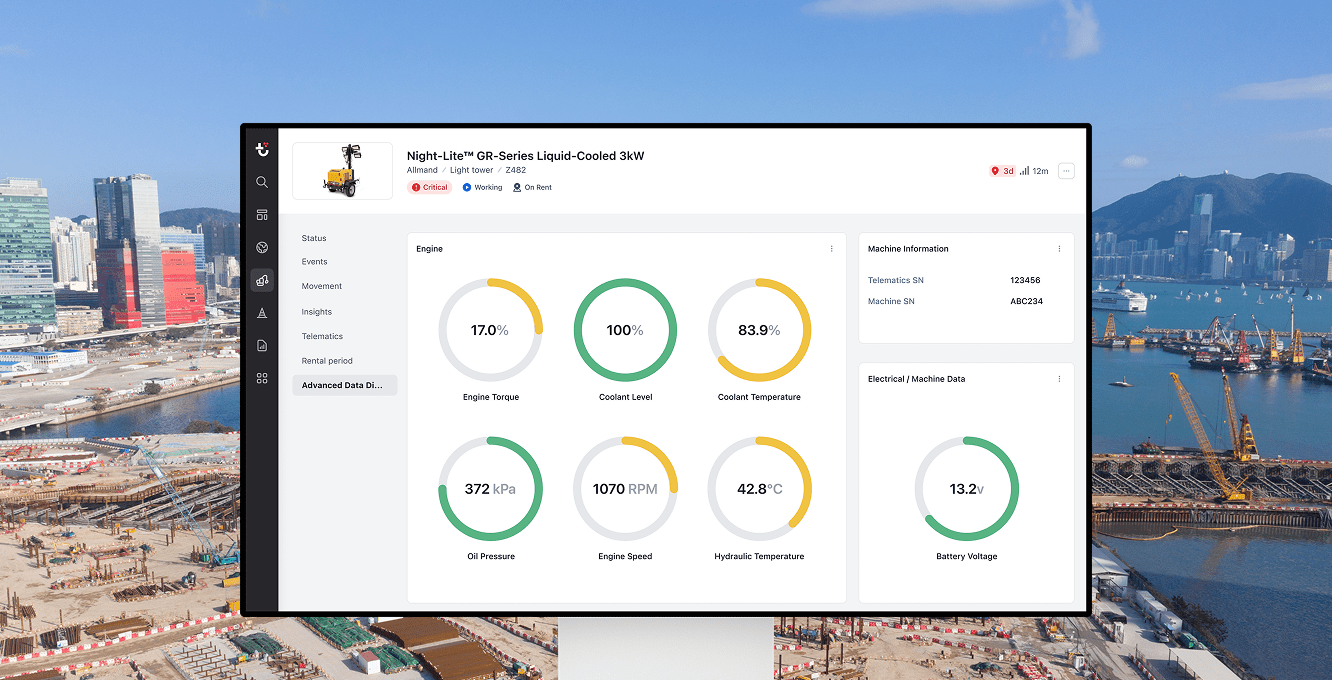

One connected platform that turns equipment data into uptime

Trackunit connects all your utilization data in one place so you can spot idle assets, prevent costly breakdowns, and keep fleet utilization at its peak.

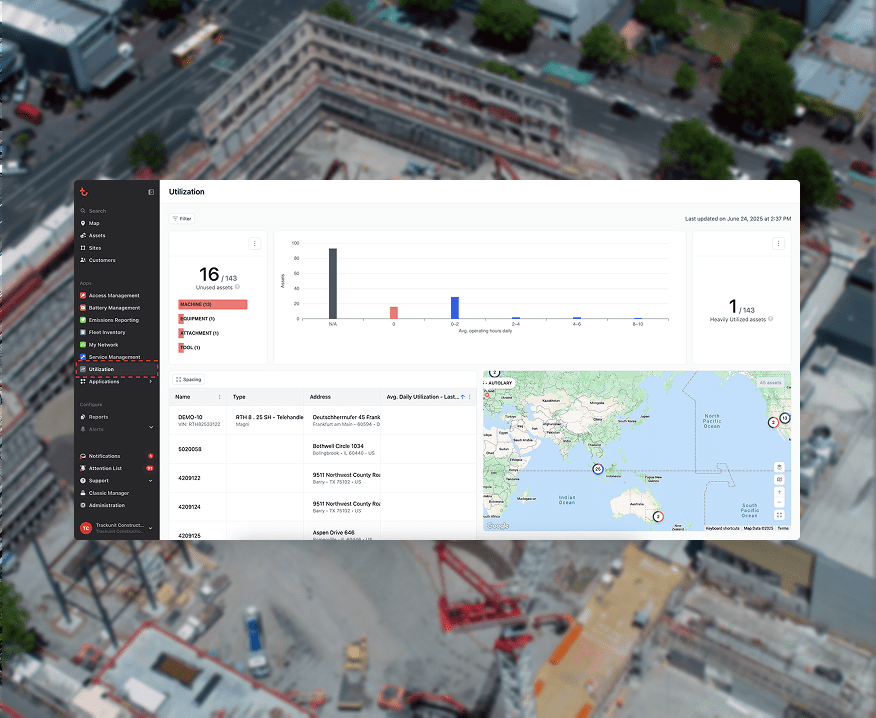

Trackunit Manager®

Report in detail your fleet activity

Drill deeper into equipment operation data to analyze working hours, idle time, and utilization patterns. Gain clarity for performance benchmarking, invoicing, and dispute resolution.

Trackunit Manager®

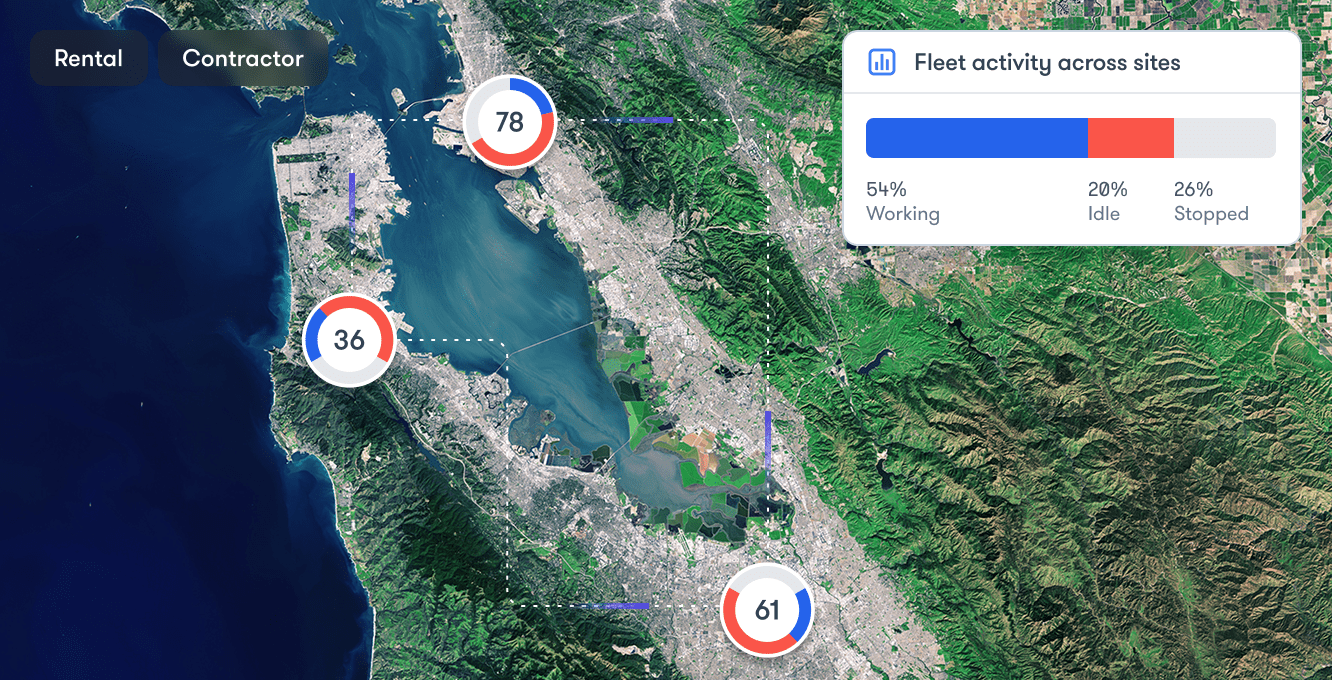

Track location and utilization data

Get a unified view of equipment performance across multiple locations. Identify where machines are underworked or overused and balance your fleet accordingly.

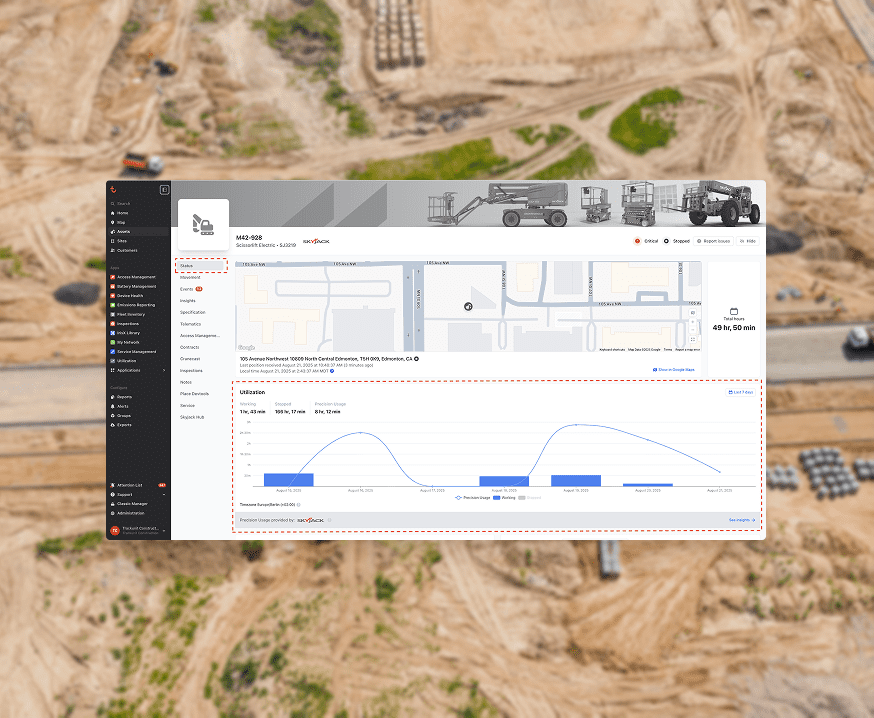

Trackunit IrisX®

Build bespoke utilization analysis

Leverage advanced analytics to uncover usage trends, capture unbilled hours, and build advanced utilization reports that unlock revenue potential.

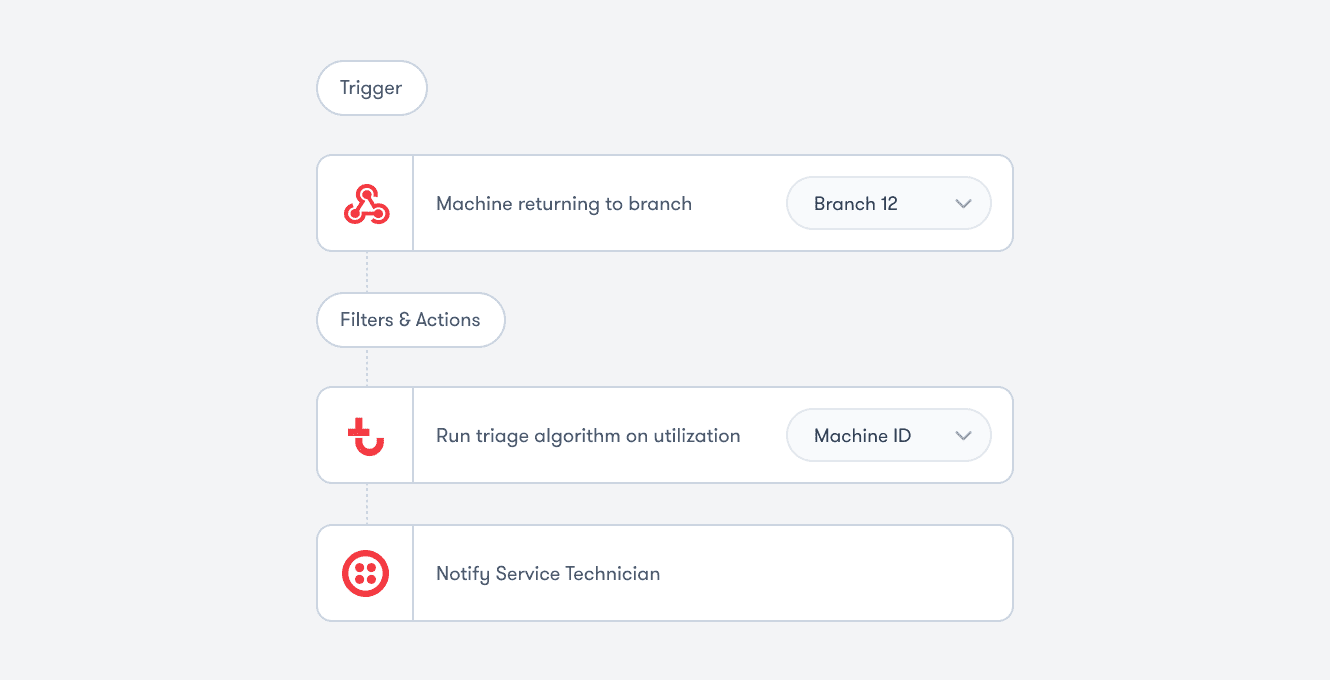

Trackunit IrisX®

Automate relocation and service workflows

Automate utilization reporting and alerts — from detecting underused assets to triggering relocation workflows or service actions.

Case Study

Increase in repeat business

8%

Increase in repeat business driven by better visibility into equipment utilization and uptime performance.

Increase in revenue

4%

Increase in revenue from extended contracts through detection of non-contractual machine use.

Cost savings

$140k+

Saved over 5 years by reducing idle time 20% on a large excavator, turning data into measurable ROI.

Connecting the ecosystem across one platform

Trackunit connects OEMs, rental companies, and contractors in one collaborative data ecosystem where utilization insights create shared value.

OEMs

Turn utilization into your competitive edge

Use real-world usage data to design smarter machines, enhance service performance, and deliver data-driven customer value.

Rentals

Increase utilization across your rental cycle

Use live site data to right-size fleets, improve time and revenue utilization, and reduce idle inventory.

Contractors

Stay ahead on every jobsite

Track utilization, uptime, and machine performance to optimize productivity and control operating costs.

See utilization across every connected asset

From large excavators to compact tools, combine utilization data from every machine, system, and OEM feed into one platform.

Trackunit Raw®

Deep connectivity for equipment

Rugged LTE-M telematics device delivering real-time location, utilization and condition data from heavy equipment.

Trackunit Spot®

Long-life tracking made simple

Self-powered slap-and-track device that reports asset location and utilization for years on an internal battery.

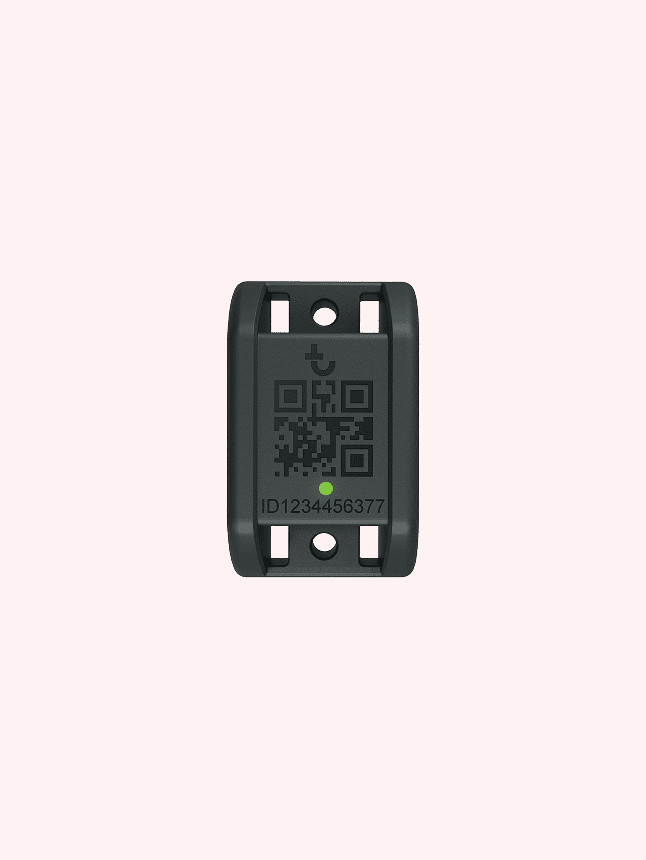

Trackunit Kin®

Smart Bluetooth® tracking for small assets

Bluetooth® tag that connects tools and small assets to construction’s largest BLE network with no power or pairing required.

Trackunit Marketplace®

Datafeeds for standardized mixed fleet data

Connect to +110 data sources to supercharge your data collection to gain valuable equipment insights.

Joel Särkkä

CIO, Renta

“Digitization has been an integral part of being able to scale the business. It forces us to think outside of the box and come up with new solutions. But we always keep in mind that the solutions we create should serve the people using them.”

Roger Rotés

Product Manager, AUSA

"We launched the AUSAnow solution together with Trackunit during 2021,” Roger Rotés, Product Manager at AUSA says. “The partnership between AUSA and Trackunit exemplifies the power of collaboration in driving operational excellence and customer satisfaction."

Jenna Reed

Director, Sunbelt Rentals

"Through our partnership with Trackunit, we are enabling a better end-to-end experience for our customers through data. Having robust equipment data from Trackunit Manager, which pulls in critical information from our IoT devices, is critical to our operations."

Dig deeper into utilization

Keep up to date on news surrounding the platform’s capabilities, development, and the technology behind it.

Request a meeting

Get hands on with the solutions that can empower your digital journey. Let’s connect and find the right time and place to explore your connectivity potential.