Maximize uptime and fleet life with actionable health insights

Turn real-time equipment data, fault codes, and service insights into proactive maintenance. Keep your fleet running, eliminating costly downtime and extending equipment life.

Turn equipment maintenance into your competitive advantage

Trackunit connects machine data, service teams, and maintenance workflows in one platform enabling proactive service to protect uptime and grow high-margin parts and service revenue.

Increase profitability

Reduce operating costs across fuel, repairs, and labor while growing revenue from parts and service sales.

Boost resale value

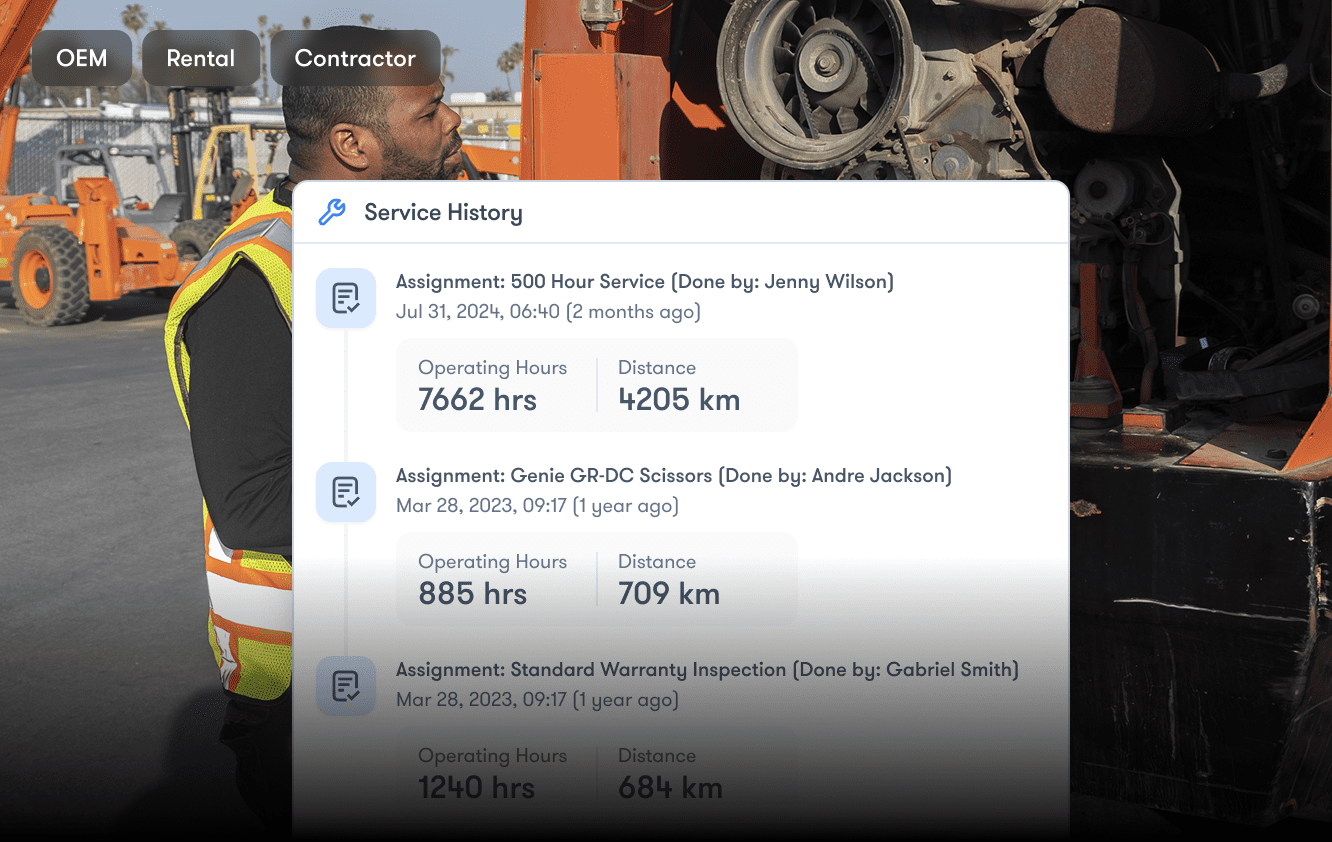

Demonstrate verifiable maintenance history into higher resale prices and lower insurance costs.

Reduce breakdowns

Prevent costly equipment failures before they happen, minimizing project delays and protecting revenue.

Cut admin time

Eliminate hours of manual data gathering and paperwork, saving technicians hours every week.

Extend equipment lifespan

Keep machines running at peak performance longer, reducing premature replacement costs.

Improve first-time fix rates

Give field teams access to fault codes and service histories, eliminating costly return trips and improving customer satisfaction.

Solve machine health challenges with connected insights

From engine faults to scheduled services, Trackunit gives every stakeholder the visibility they need for smarter equipment maintenance and maximum uptime.

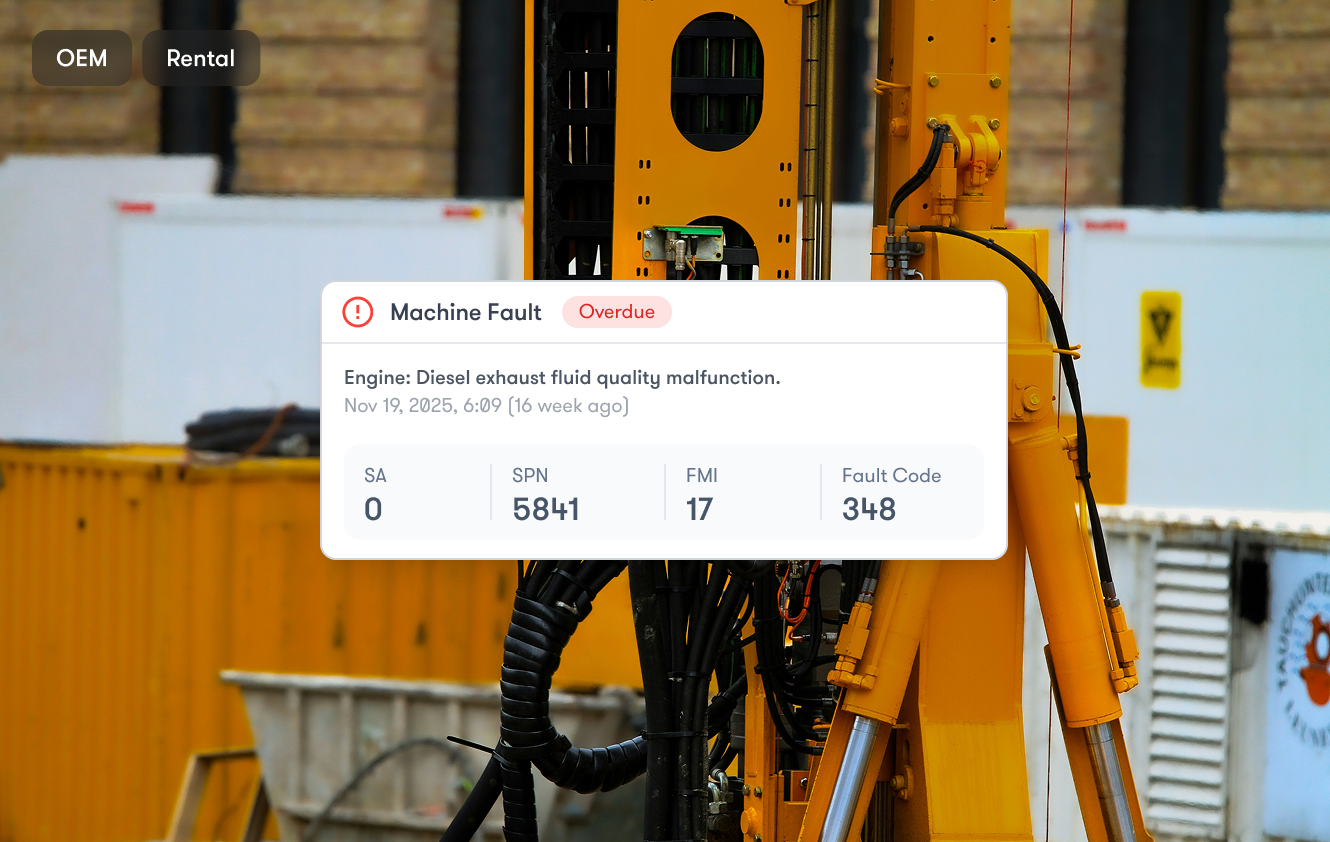

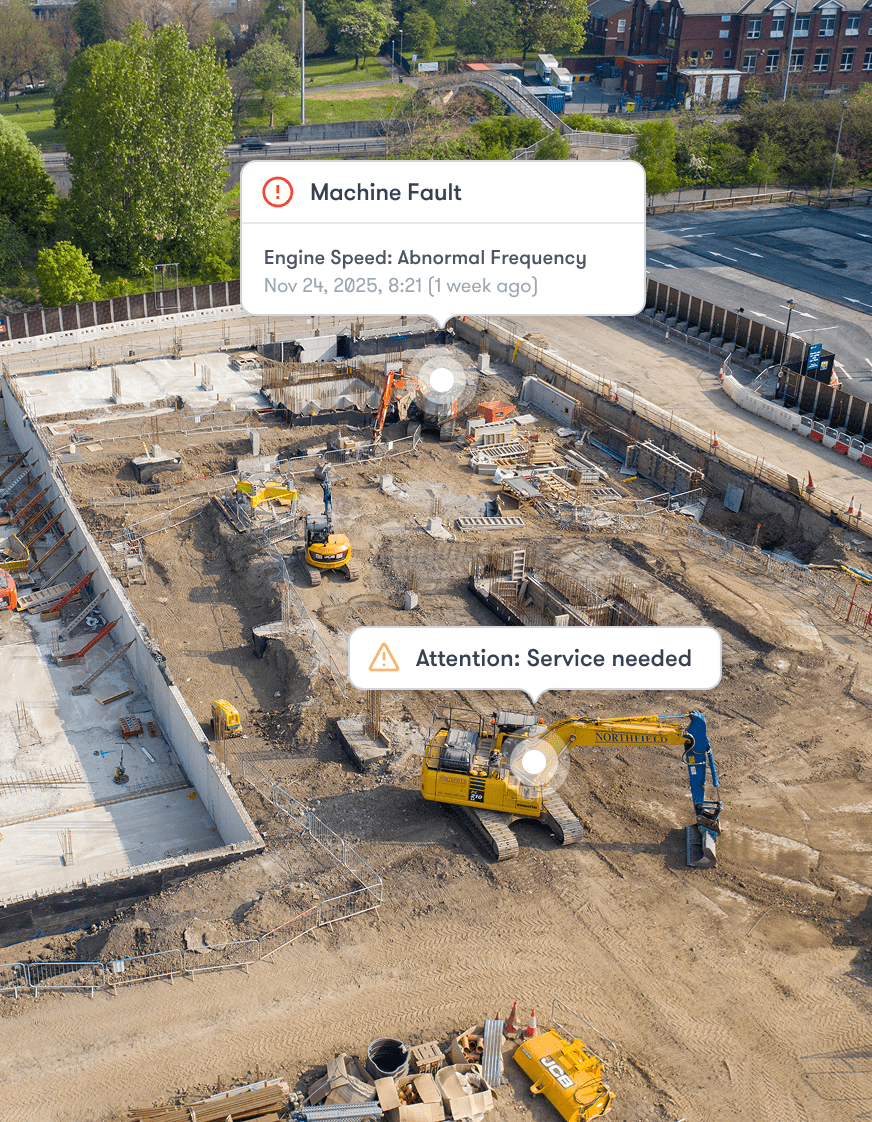

Detect early machine faults

Spot performance issues in real time by monitoring engine hours, fault codes, and CAN data. Prevent small anomalies from turning into costly breakdowns.

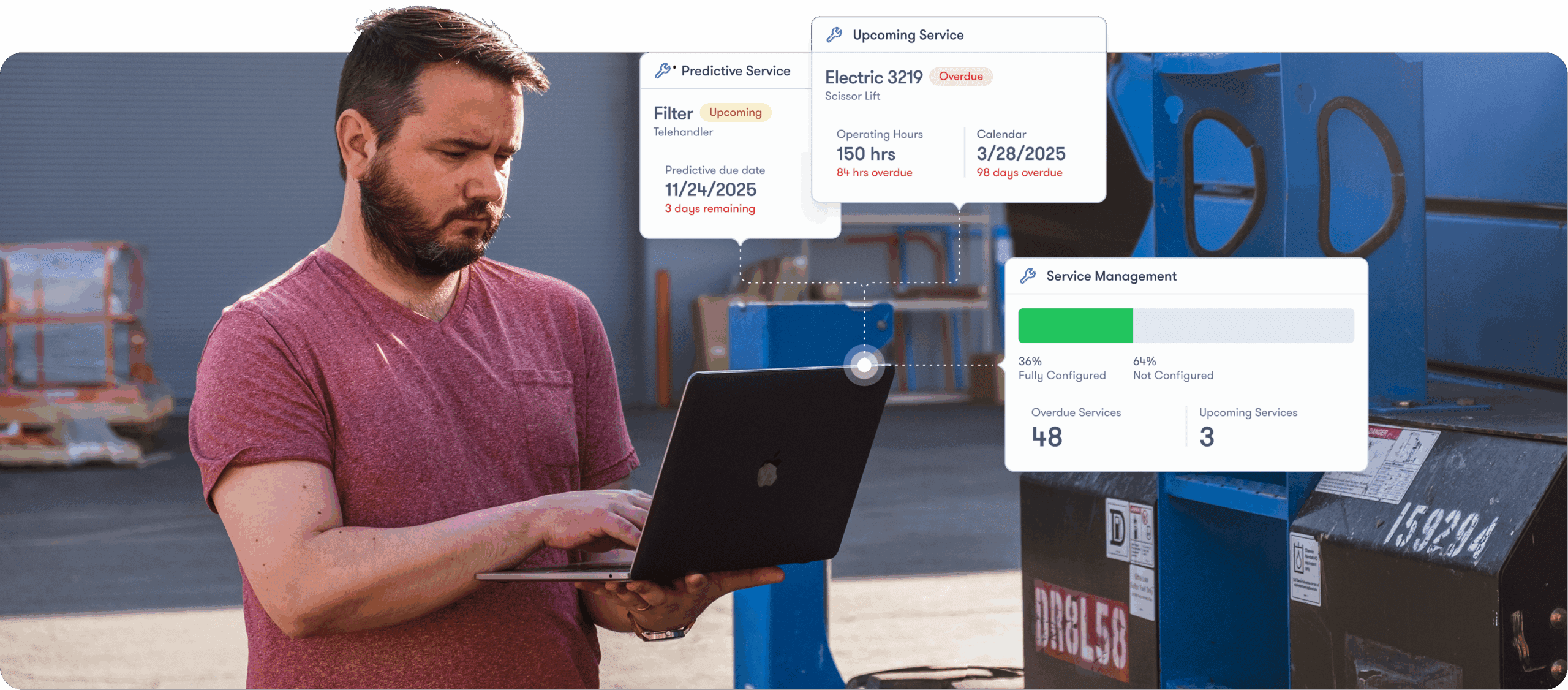

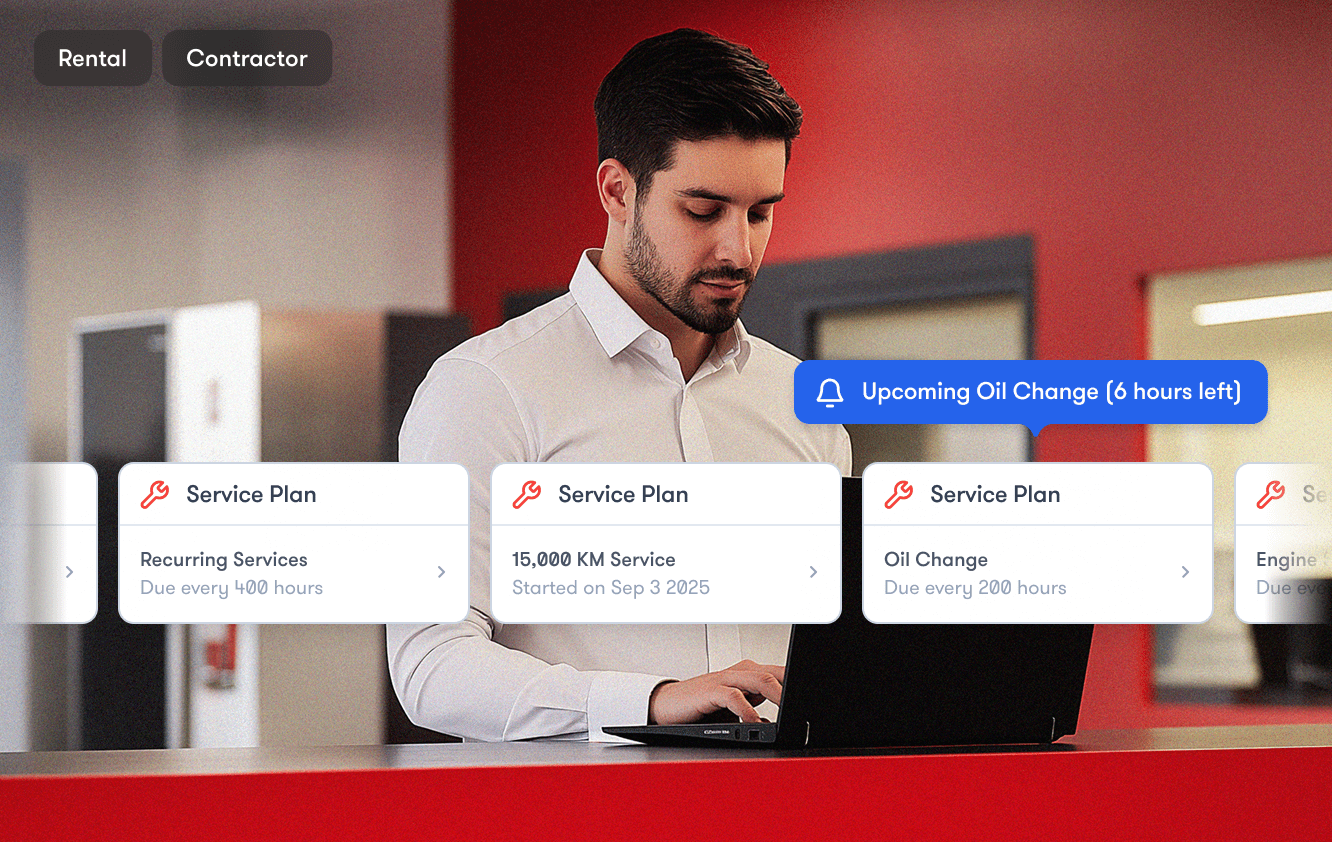

Automate service scheduling

Close the gap between usage and maintenance by turning engine hours and operating conditions into automatic service triggers.

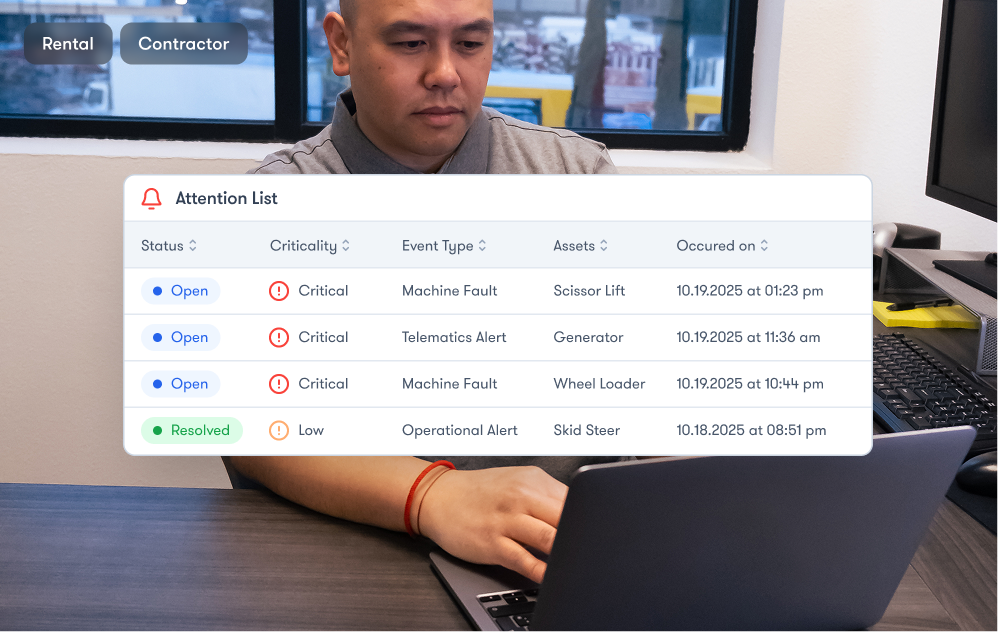

Prioritize critical repairs

See which machines need immediate attention to address the most critical issues first, preventing costly failures.

Diagnose issues before dispatch

Remotely identify faults before sending a technician. Cut travel time, increase first-time fix rates, and unlock recurring parts and service revenue.

Track maintenance history

Build a complete digital service record for each machine supporting warranty claims, improving resale value, and proving compliance at any time.

Optimize parts inventory

Analyze maintenance and fleet usage patterns to forecast which parts you’ll need and when, reducing emergency orders and inventory carrying costs.

Case study

Reduction of unplanned downtime

18%

by preventing costly breakdowns when shifting from reactive to proactive maintenance strategies.

Time saved per day for service technicians

45 mins

through faster issue resolution and optimized service scheduling.

Time saved per month on yard & depot

25 hours

through automated service workflows and accurate historical documentation

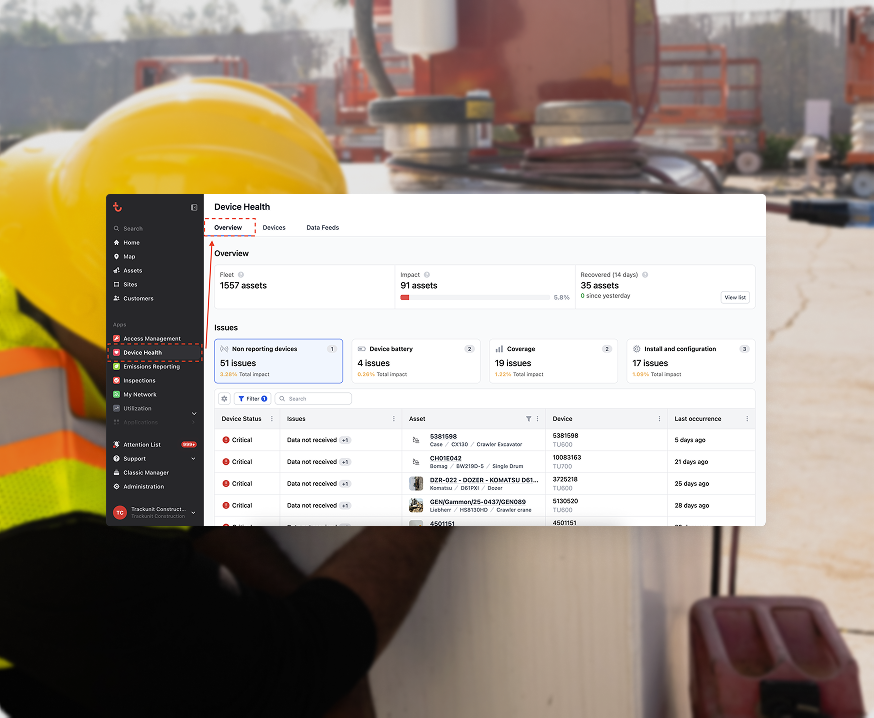

One connected platform to monitor, diagnose and maintain your entire fleet

Trackunit connects all your fleet data in one place so you can prevent breakdowns, optimize maintenance, and keep equipment running at peak performance.

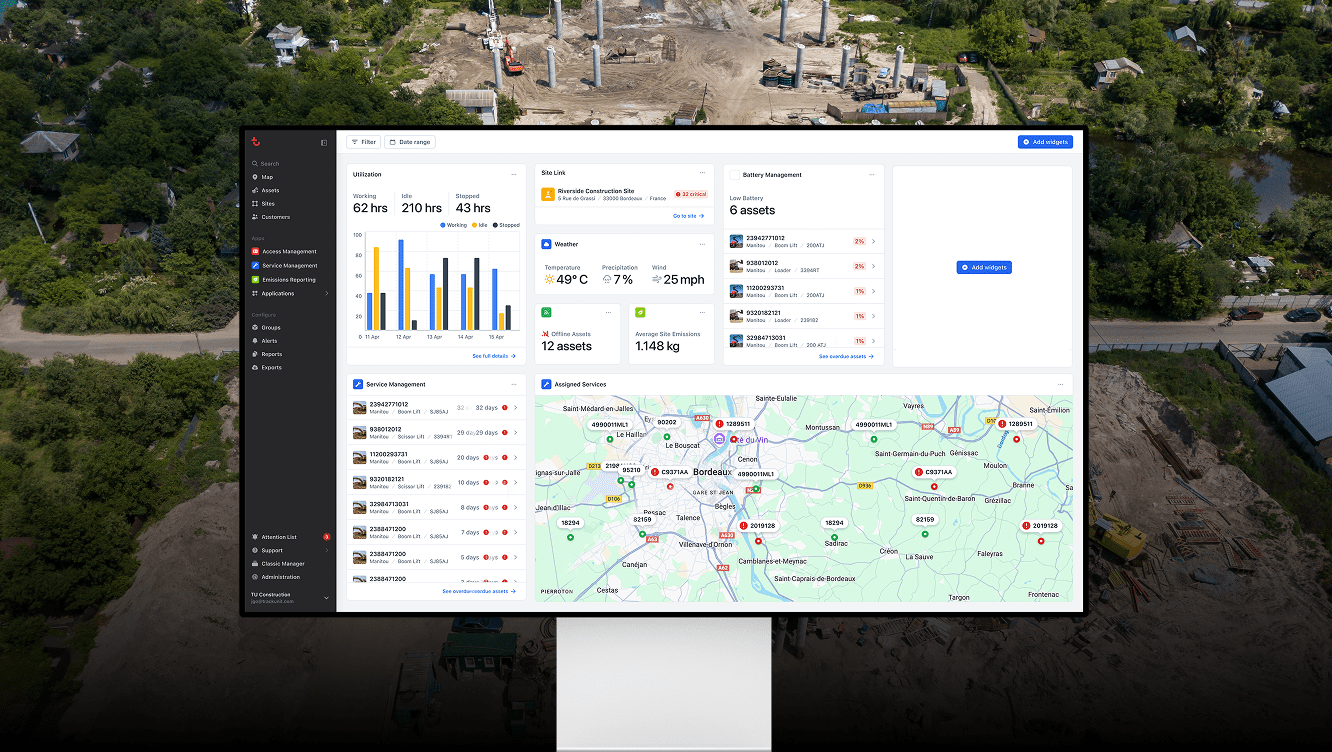

Trackunit Manager®

Centralize fleet health management

Monitor fault codes, engine hours, and utilization for every machine in one single view.

Trackunit Manager®

Streamline maintenance workflows

Apply service schedules, assign providers, and track completion across your fleet.

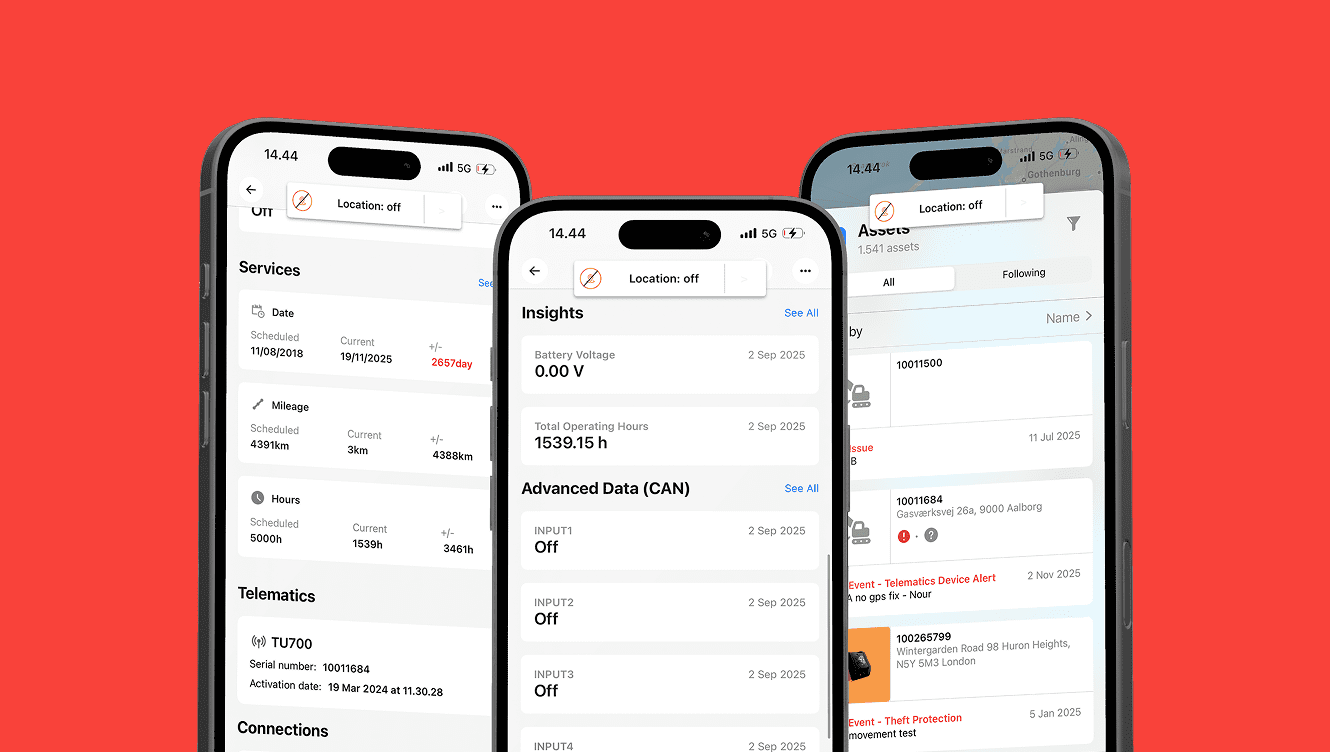

Trackunit Go®

Manage service on the go

Give technicians mobile access to diagnostics, histories, and work orders.

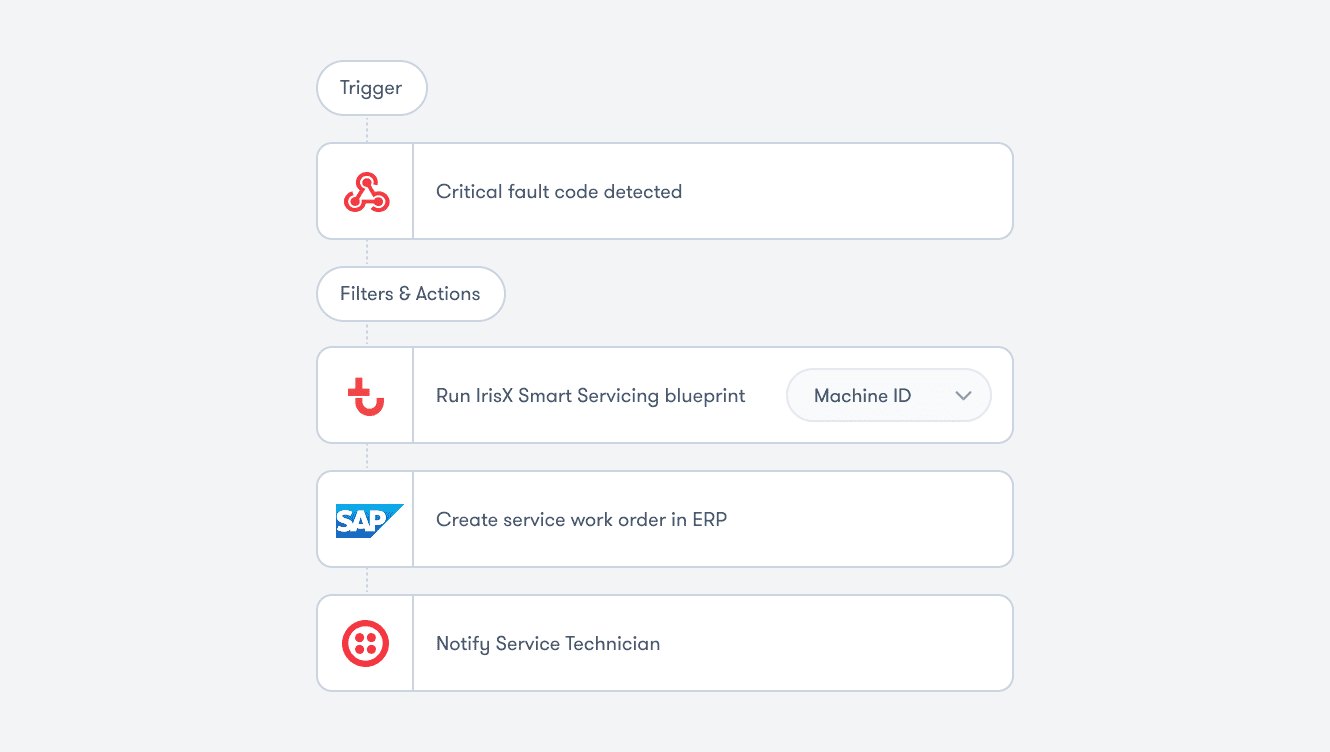

Trackunit IrisX®

Automate actions based on health data

Set thresholds to trigger instant notifications when intervention is needed.

Access OEM specific diagnostics

Get manufacturer-level fault insights integrated directly into Trackunit. Diagnose engine issues faster and more accurately with specialized apps.

Trackunit Marketplace App

Cummins Connected Diagnostics

Diagnose Cummins engine faults remotely with real-time alerts, severity rankings, and service recommendations that prevent breakdowns.

Trackunit Marketplace App

Perkins Engine Insights

Eliminate unplanned downtime with enhanced fault descriptions and recommended actions for Perkins-powered equipment.

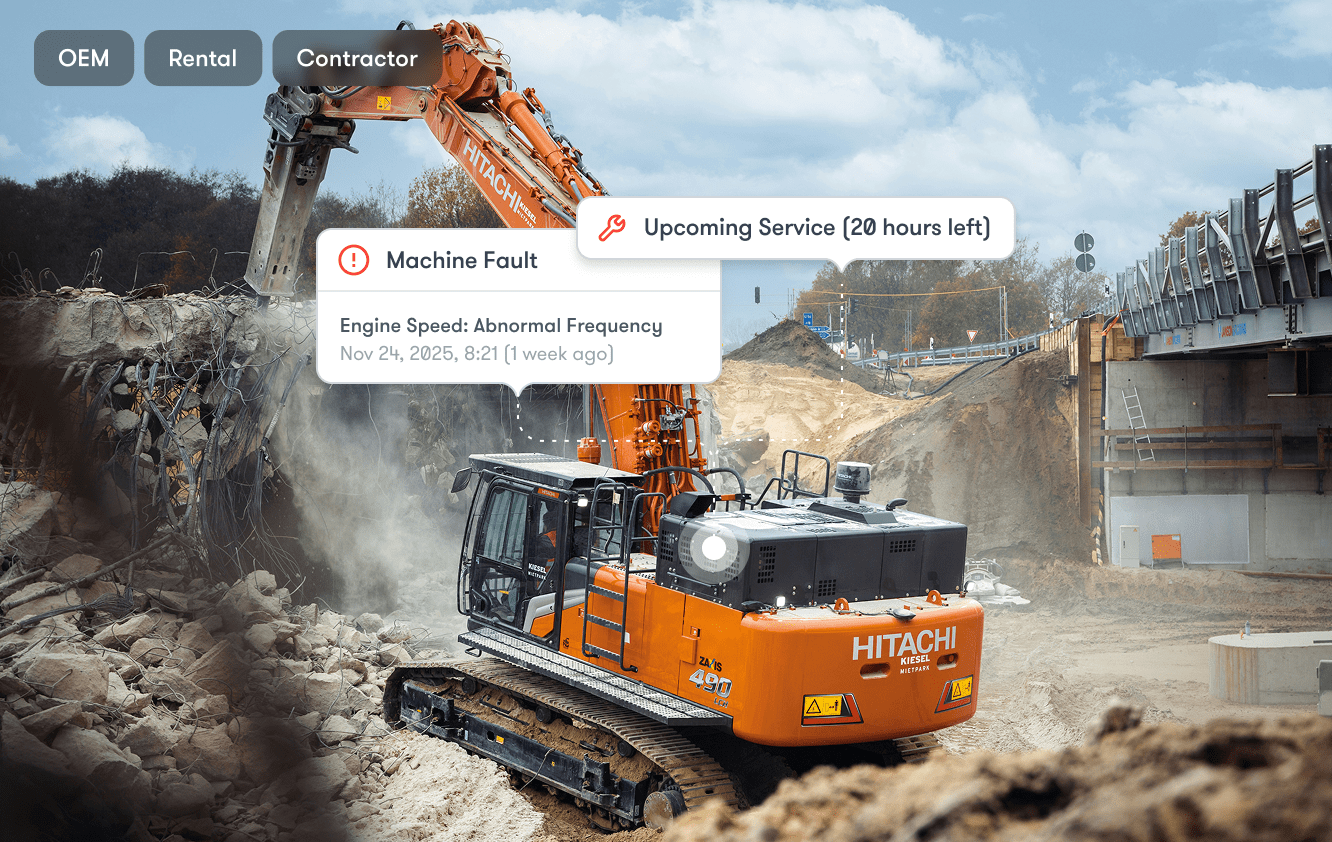

Connecting the ecosystem across one platform

Trackunit bridges OEMs, service providers, and equipment owners with real-time insights that drive better maintenance outcomes.

OEMs

Deliver proactive support

Use real-world machine data to improve product design, deliver proactive service, and grow revenue from parts and service plans.

Rentals

Maximize fleet availability

Keep rental equipment ready to deploy with automated maintenance, remote diagnostics, and service histories that minimize off-rent time.

Contractors

Eliminate project delays

Prevent equipment failures from halting progress by monitoring machine health across jobsites and scheduling maintenance during planned downtime.

We’ve got answers to your top questions about equipment maintenance

How do connected insights support equipment maintenance?

By combining engine hours, fault codes and other signals in one view, insights highlight which assets need attention first.

What information is available to support equipment maintenance decisions?

Users see machine status, fault events, service history and usage-based upcoming maintenance to plan work orders and site visits.

Who typically uses these insights?

Maintenance planners, workshop teams, site and fleet managers share one data set to discuss machine health and schedule work.

Do these insights work across different brands and models?

Yes. Equipment data from different OEMs are brought into one view, so mixed fleets can be monitored and discussed in the same way.

See machine health across every connected assets

From large excavators to compact tools, combine utilization data from every machine, system, and OEM feed into one platform, to keep all equipment healthy and productive.

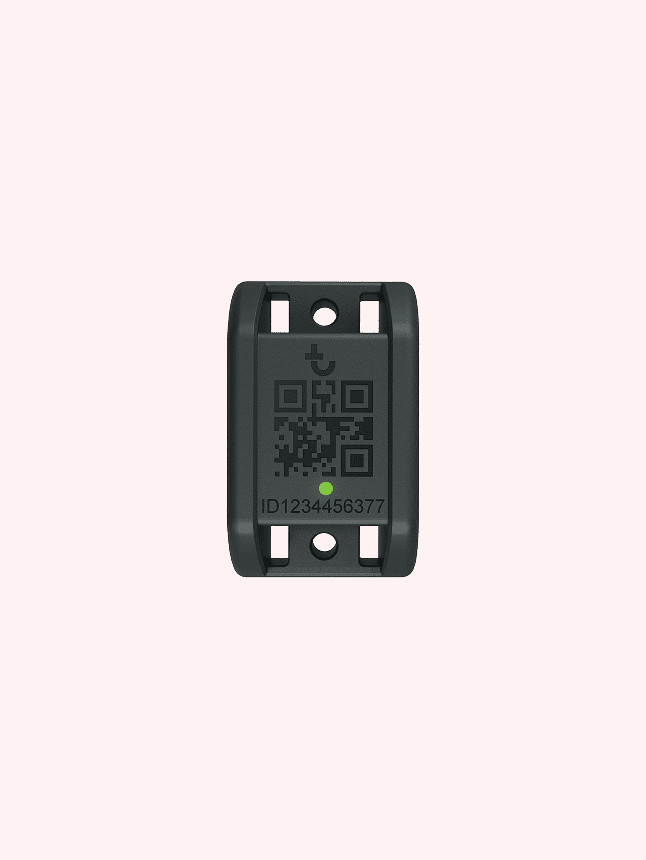

Trackunit Raw

Deep connectivity for equipment

Rugged LTE-M telematics device delivering real-time location, utilization and condition data from heavy equipment.

Trackunit Spot

Long-life tracking made simple

Self-powered slap-and-track device that reports asset location and utilization for years on an internal battery.

Trackunit Kin

Smart Bluetooth® tracking for small assets

Bluetooth® tag that connects tools and small assets to construction’s largest BLE network with no power or pairing required.

Trackunit Marketplace

Datafeeds for standardized mixed fleet data

Connect to 110+ data sources to supercharge your data collection to gain valuable equipment insights.

Join the best in business

Trusted by leading OEMs, rental companies, contractors, and partners to unlock the full value of their fleets and equipment.

Joel Särkkä

CIO, Renta

“Digitization has been an integral part of being able to scale the business. It forces us to think outside of the box and come up with new solutions. But we always keep in mind that the solutions we create should serve the people using them.”

Roger Rotés

Product Manager, AUSA

"We launched the AUSAnow solution together with Trackunit during 2021,” Roger Rotés, Product Manager at AUSA says. “The partnership between AUSA and Trackunit exemplifies the power of collaboration in driving operational excellence and customer satisfaction."

Jenna Reed

Director, Sunbelt Rentals

"Through our partnership with Trackunit, we are enabling a better end-to-end experience for our customers through data. Having robust equipment data from Trackunit Manager, which pulls in critical information from our IoT devices, is critical to our operations."

Dig deeper into fleet health

Keep up to date on news and articles surrounding the platform’s capabilities, development, and the technology behind it.

Request a meeting

Get hands on with the solutions that can empower your digital journey. Let’s connect and find the right time and place to explore your connectivity potential.