Sometimes a partnership is a slow burner. Sometimes, it sizzles. And it’s the latter that applies best after Epiroc’s Attachments division introduced InSite™, a connected solution that brings total visibility and complete fleet control to hydraulic tools.

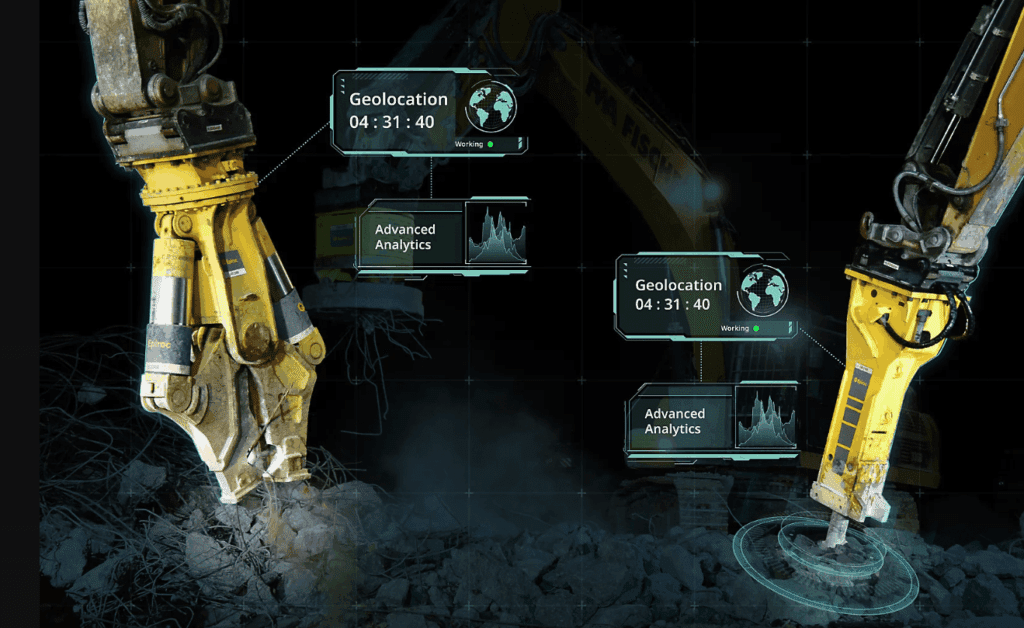

Powered by Trackunit’s IrisX platform, InSite™ gives customers the ability to track, monitor, and service attachments in real time, turning previously unseen tools into predictable, safe, and high-performing assets that drive improvements in uptime.

“We started seeing strong traction in the market within weeks of introducing InSite™,” says Thomas Bejefalk, head of digital solutions at Epiroc Attachments. “Customers were actively asking for connected products. It’s the kind of demand we haven’t experienced in years.

“We started seeing strong traction in the market within weeks of introducing InSite™…It’s the kind of demand we haven’t experienced in years.”

“We’re excited to see how this collaboration with Trackunit develops as we unlock the value of connected attachment data,” he says. “By combining our expertise with Trackunit’s technology, we are empowering our customers to act faster, make smarter decisions, and achieve safer, more efficient operations on every jobsite.”

That matters because, in the heavy-duty equipment world, attachments are often the unsung heroes, doing the tough work, often under the radar. But at Epiroc InSite™, they’re becoming digital tools in their own right, thanks to a strategic focus on telematics.

“By combining our expertise with Trackunit’s technology, we can help our customers act faster, make smarter decisions, and achieve safer, more efficient operations on every jobsite.”

For Epiroc, this digital evolution isn’t about novelty, it’s about value.

“Telematics is really important in terms of actually getting the most out of your products and understanding that you use them in an optimized way,” Bejefalk says. “On the demolition side, construction side, or even in rental, you need to know your equipment is being used properly and proactively serviced.”

The traditional repair model is reactive. A machine fails, then a technician is dispatched. But Epiroc InSite™ is helping customers flip that equation.

“With telematics, we are accelerating everything,” says Bejefalk. “When things are due for service, we as a service provider can call the customer, notify them through the data, and ensure that we have a technician on site before anything breaks down.”

That shift offers huge savings in time, safety, and operational cost. “There are humongous savings in productivity for our customers,” he says.

The benefits of connectivity go beyond service schedules. It also improves on-site operations, especially in challenging conditions.

“In demolition, you’re literally tearing down buildings,” says Bejefalk. “It’s usually a long project with a massive amount of equipment moving between cities. And in places like Scandinavia, where I come from, seasons change everything. You add snow, and suddenly everything turns white. You don’t know where you put your stuff.”

Instead of walking around a jobsite in the cold searching for tools, Epiroc’s integrated solution now makes location tracking effortless. “You can just pick up your phone, see where your equipment is, and continue working,” he says. “You save time. You boost productivity.”

A major strength of the Epiroc–Trackunit partnership is a shared approach to user experience: simplicity.

“When it comes to digital solutions, the biggest feedback I’ve gotten is about how we make it simple,” says Bejefalk. “Avoiding complexity, providing guidance… it’s basically click, connect, and go.”

“It’s not something cumbersome. You’re not dealing with different sources and systems. It’s a one-stop shop.”

That mindset is built into the system design. “It’s not something cumbersome. You’re not dealing with different sources and systems. It’s a one-stop shop. You have a fleet overview, including attachments. It gives you the insights to propel your operations forward.”

Looking ahead, Epiroc is doubling down on its telematics roadmap. That includes expanding coverage across its entire attachment portfolio, from hydraulic to mechanical tools.

“We’ll continue investing to ensure we have very high connectivity coverage and a high data saturation rate,” Bejefalk says. “The more data we get, the better the product experience for the end user.”

His message to customers is clear: “Connect. Connect with us. We’re extremely driven by providing customer value and if we’re not focused on that, then we’re doing the wrong thing.”

For Bejefalk, digital transformation is no longer theoretical. It is with Epiroc InSite™ already happening. Electrification is accelerating connectivity, and the OEM is riding that wave, reshaping its position in the market.

“We’re not just a premium hardware manufacturer anymore,” he adds. “We’re becoming a premium service provider when it comes to digital.”