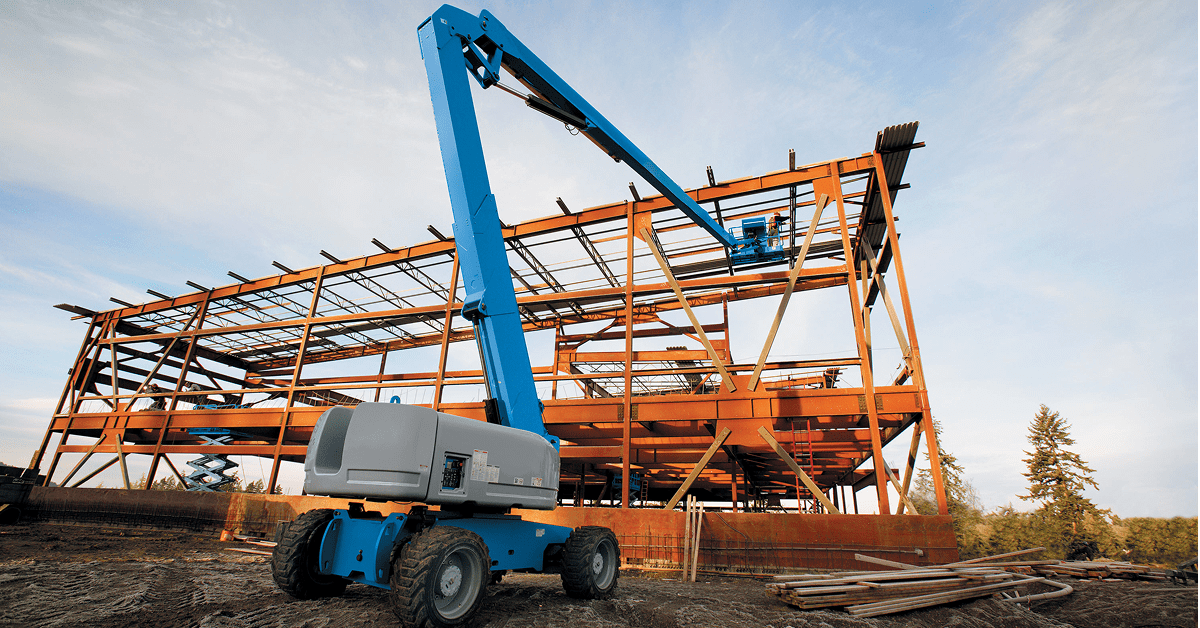

The future of the OEM business model is changing. Success no longer ends at the point of sale, it spans across the entire equipment lifecycle. For OEMs, this shift opens a powerful opportunity to build an aftermarket strategy that delivers predictable, recurring revenue through connected equipment, predictive maintenance, and continuous customer engagement.

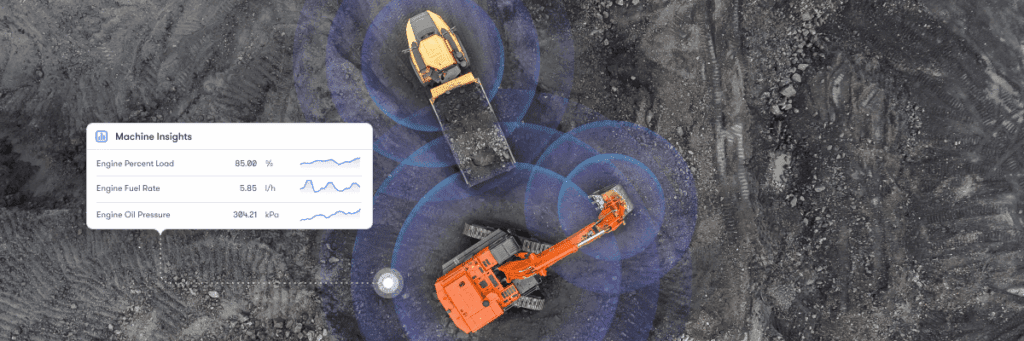

In the connected era, data isn’t just collected, it’s acted upon. With real-time insights OEMs can detect small issues before they become big ones, enabling technicians to schedule interventions proactively.

Trackunit’s IrisX, an operating data platform built specifically for construction, combines equipment insights, machine learning, and analytics to identify anomalies and forecast service needs. Predictive maintenance will transform OEMs from repairers of downtime into enablers of uptime. By offering predictive maintenance as part of an OEM aftermarket service program, manufacturers create new touchpoints with customers and unlock service-based revenue. Every connected machine becomes an ongoing relationship rather than a one-time transaction.

According to Deloitte, predictive maintenance can increase equipment uptime by 10–20%, reduce breakdowns by up to 70%, and cut maintenance costs by around 25%. Clear proof that connected insights translate directly into operational and financial gains.

“Predictive maintenance transforms OEMs from repairers of downtime into enablers of uptime.”

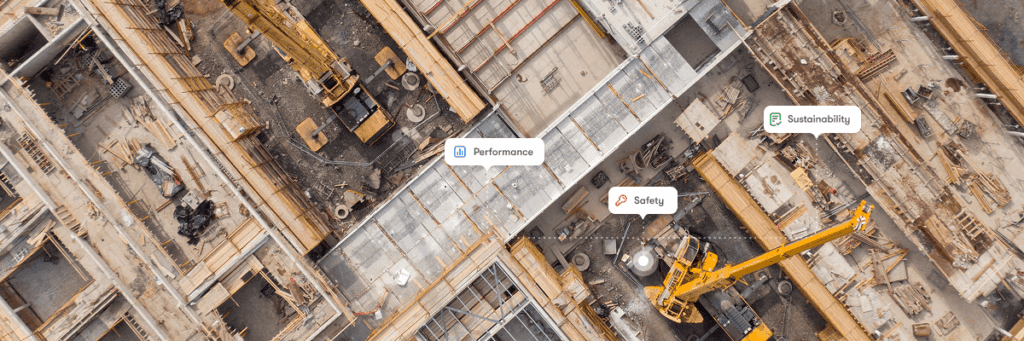

An effective lifecycle management strategy brings every stage of equipment ownership together, from design to decommissioning. For OEMs, it means moving beyond selling machines to offering integrated solutions that optimize performance, safety, and sustainability throughout the asset’s life.

With Trackunit IrisX, OEMs can monitor utilization, performance trends, and service intervals across their global fleets in real time. This data helps teams improve product design, manage warranties efficiently, and deliver tailored maintenance programs that build customer trust.

When OEMs can demonstrate the total value of uptime over time, they position themselves as indispensable partners, not just suppliers.

“When OEMs can demonstrate the total value of uptime over time, they position themselves as indispensable partners.”

Data connectivity is the backbone of every modern OEM aftermarket strategy. By uniting machine data, service records, and customer feedback within one platform, Trackunit enables OEMs to create a single source of truth.

That shared visibility empowers OEMs, dealers, and end users to collaborate seamlessly. That means shortening repair cycles, increasing parts availability, and improving fleet utilization. When every machine tells its story, OEMs can build smarter, more profitable relationships.

“When every machine tells its story, OEMs can build smarter, more profitable relationships.”

Leading OEMs are already shifting toward as-a-service models, using data-driven insights to keep machines in optimal condition and customers productive. With Trackunit, OEMs gain the technology foundation to move confidently into this next era of connected construction, where uptime is the product, and trust is the differentiator.

The transformation starts with visibility, and scales through insight. Trackunit helps OEMs design aftermarket strategies that grow with every connected machine in the field, turning equipment data into measurable business impact.

With the strategy in place, the next step is seeing how connected machines create a stronger, more profitable aftermarket. Learn how leading OEMs use data to elevate service and performance.