Let data lead the way to

sustainability outcomes

Trackunit offers automated, usage-based tracking that unifies emissions data from every machine, site, and region so you can operate with confidence, ensure compliance, and thrive in the construction industry.

Purpose-built emissions tracking just for construction

Built on real-world insights, adaptable to any data quality, and powered by trusted CO₂ factors — Trackunit’s data model ensures every machine’s emissions are consistently captured and factored.

Bottom Up Tracking

We prioritize direct measurement for highest accuracy. If unavailable, we rely on indirect data (load, RPM, history) for reliable emissions estimates.

Trusted CO₂ Standards

Leveraging EPA combustion factors ensures accurate, consistent, and benchmark-aligned emissions data for credible sustainability reporting.

Real-World Reference Data

Powered by usage data from over 8,000+ construction equipment makes & models, Trackunit delivers robust, industry-tested emissions estimates.

Ever-Evolving Accuracy

Our data model delivers robust, industry-tested emissions estimates. Plus each data point refines the model for increasingly precise estimates.

Sustainability Dedication

Enabled by Trackunit’s dedicated team of data scientists and developers our solution adapts to the industry’s shifting sustainability demands.

Exclusive Data Advantage

Trackunit leverages real-world data from over 3 million connected assets, offering insights unavailable anywhere else in the market.

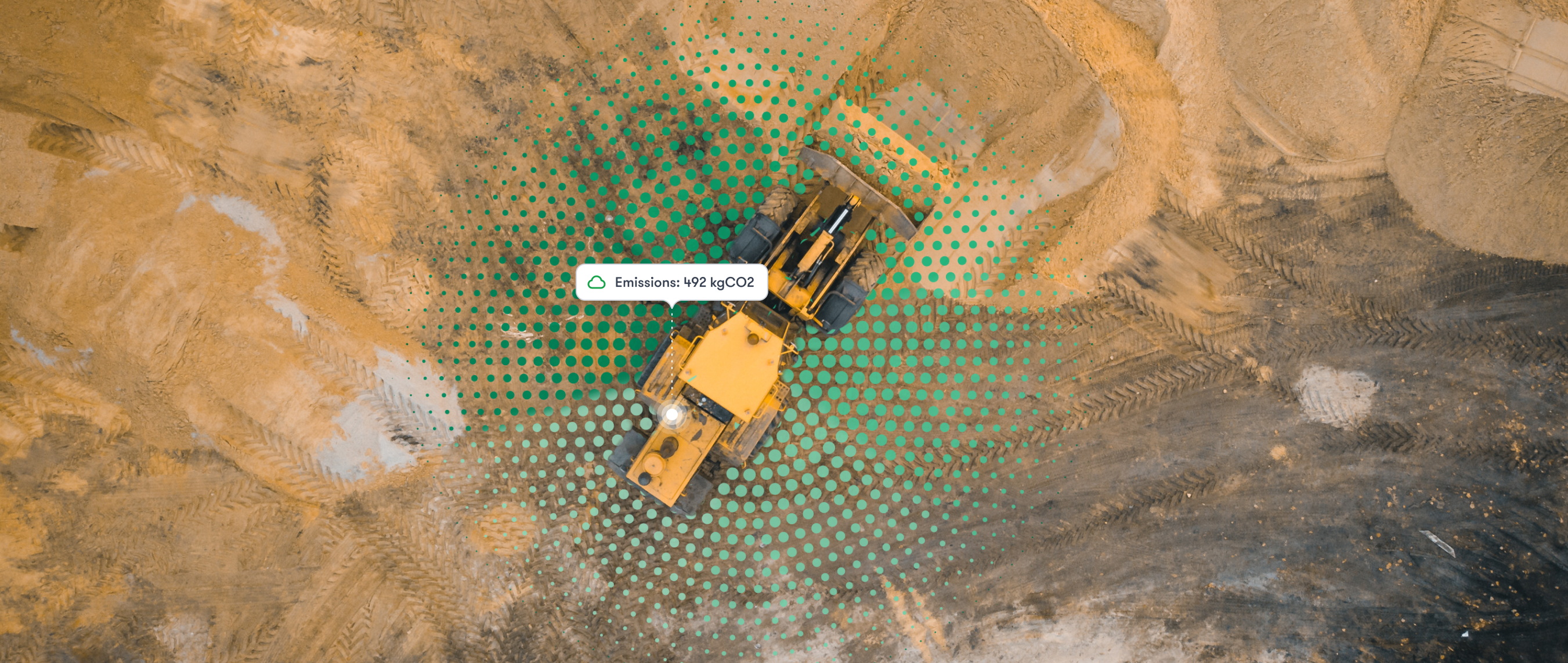

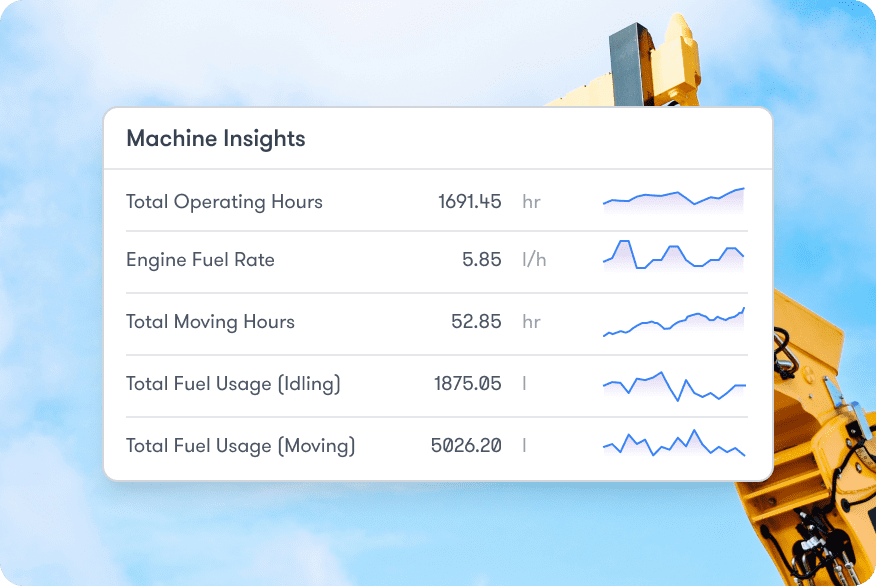

Emissions made visible, so you can take action to transform results

Track and reduce equipment emissions while saving on fuel with Trackunit’s Emissions Reporting. This comprehensive platform leverages continuous machine data and fleet-wide analysis, enabling you to monitor, manage, and report fuel use and emissions to meet your business and sustainability goals.

Complete visibility

Drill down or across the fleet

With fuel and emissions tracking per asset or across your entire fleet, you can drill down or across the fleet to know exactly where things stand with emissions, plus eliminate time spent on manual guesswork.

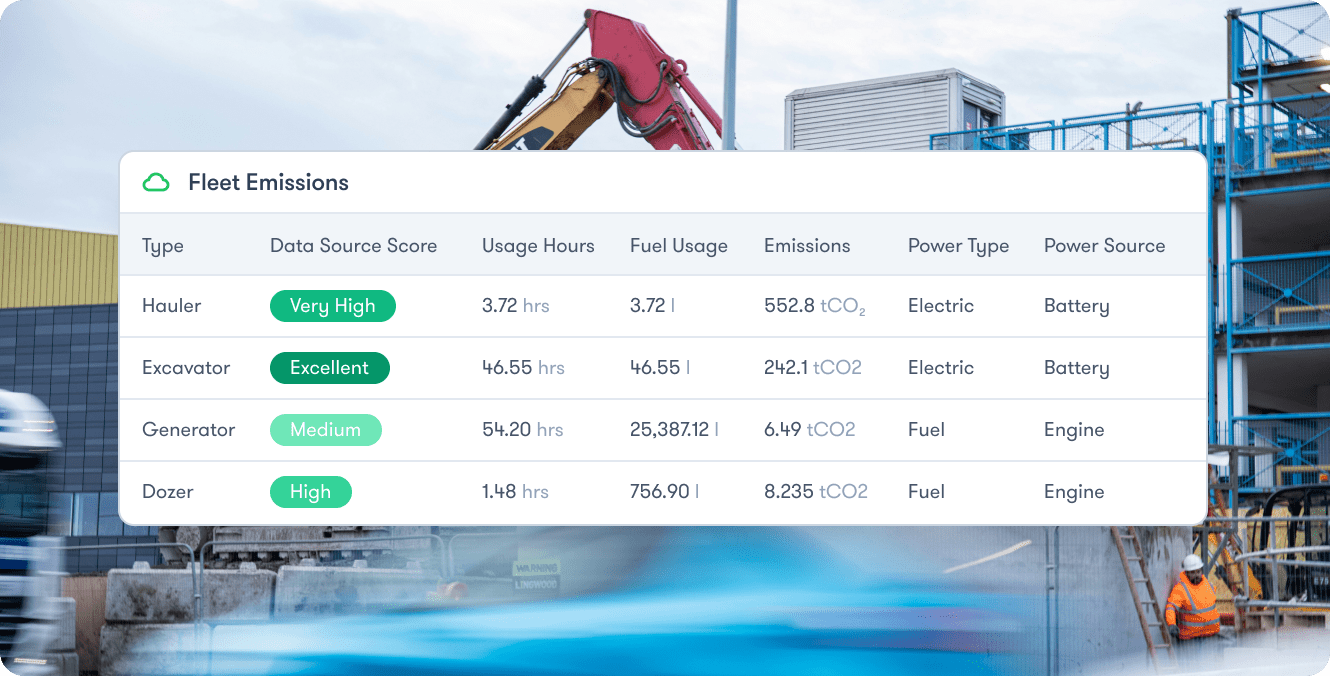

Mixed fleet coverage

No machine left behind

With emissions tracking across every make & model of construction equipment, including fuel and electric, you can rest assured that we’ve captured each and every one of your connected asset types.

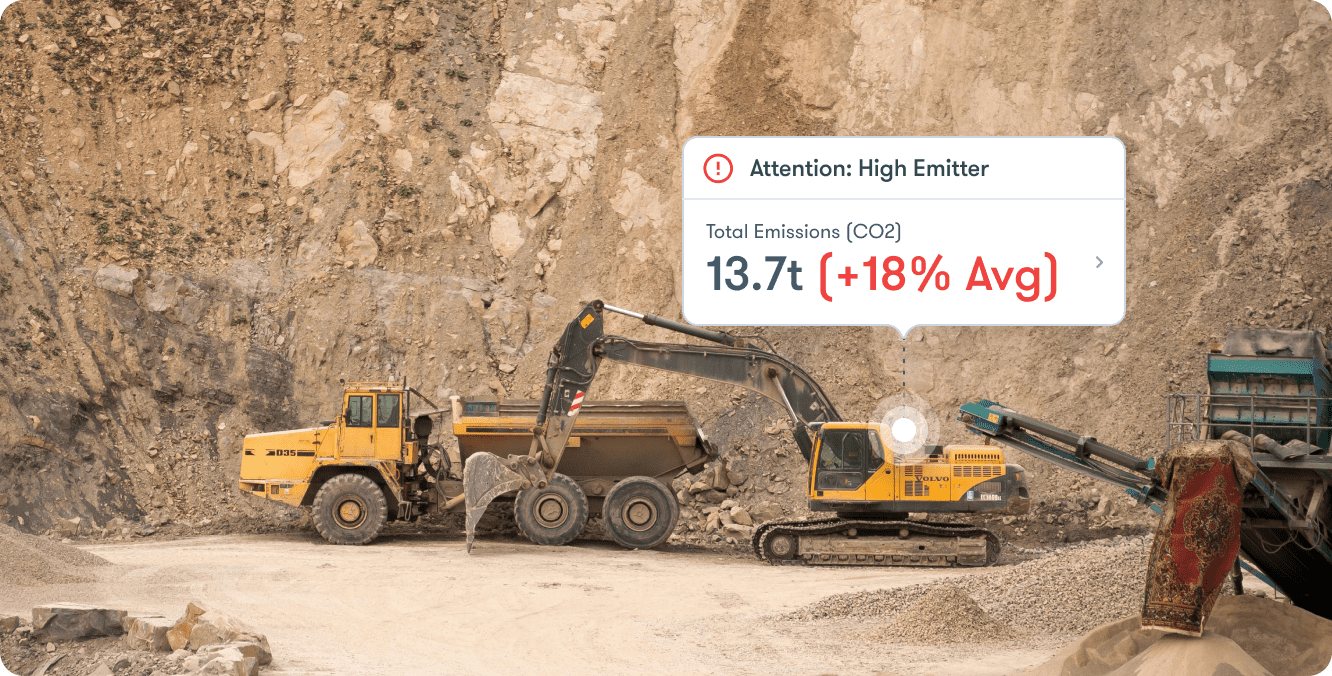

Green fleet

Spot and replace high emitters

With total monthly emissions and asset-level details you can quickly spot high-emission machinery and replace it with cleaner alternatives to adhere to project and site targets, plus drive operational efficiency and sustainability.

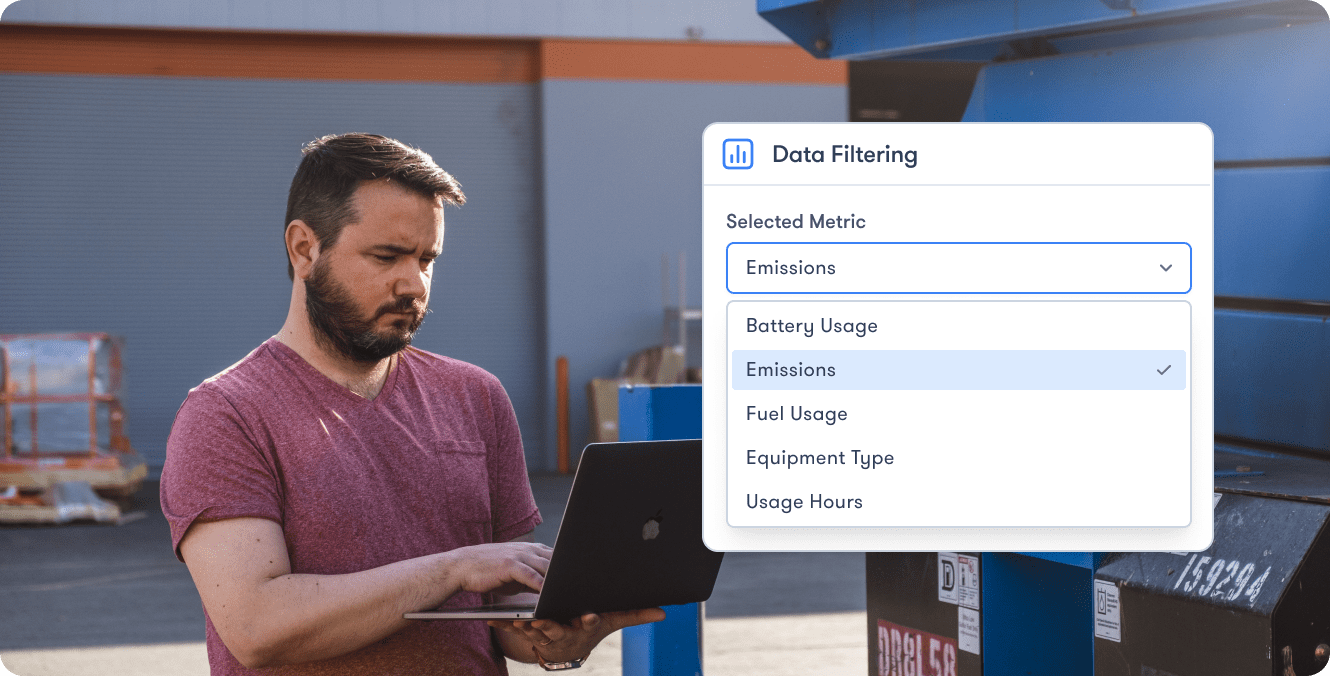

Value driving data

Unlock hidden insights

With data filtering by equipment type, operating hours, fuel and energy used, plus more, unlock instant insights to realize cost-savings and drive business value.

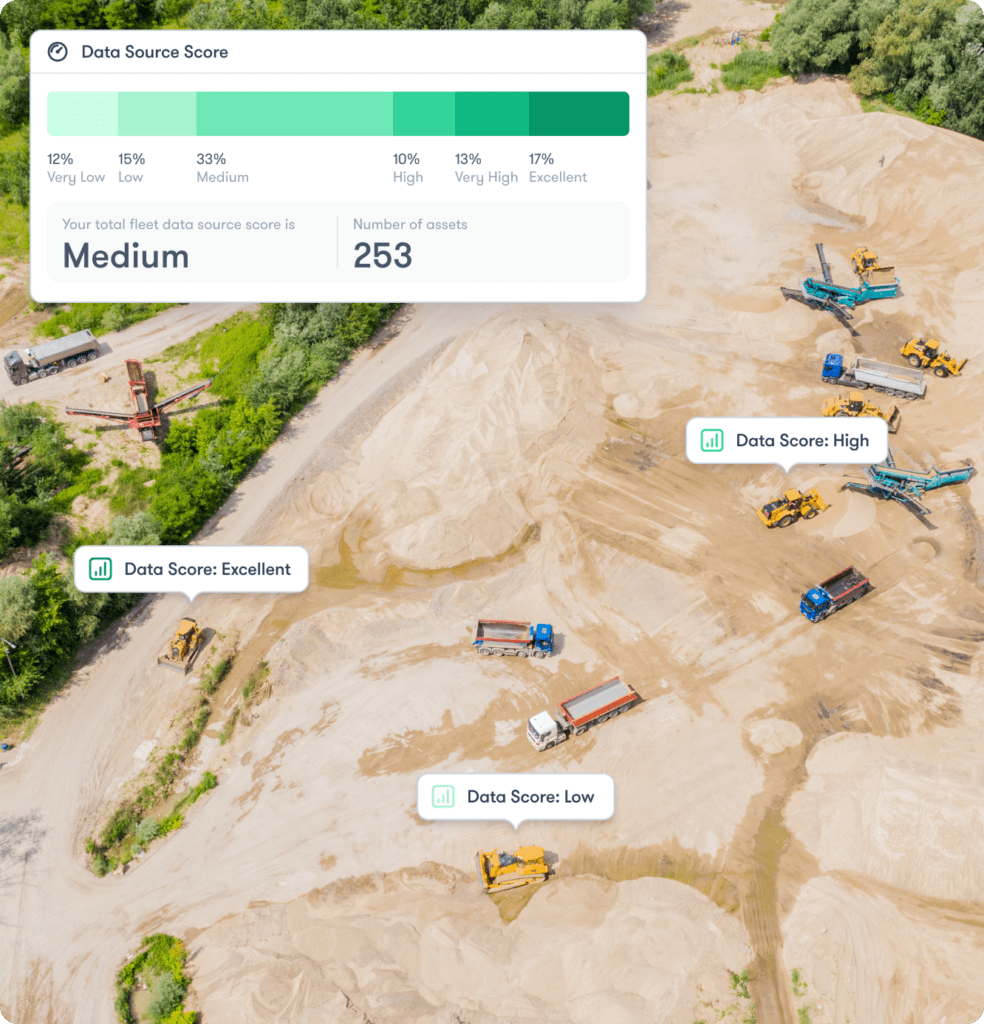

How Data Scoring works

Trackunit Emissions Reporting includes a score for each asset to highlight if action is required to improve data inputs to get more accurate emissions numbers across the fleet. Users can follow these easy steps to quickly boost the accuracy of emissions measurements.

Step 1

Score check

Check the Data Scoring dashboard for a full fleet score.

Step 2

Drill deeper

Drill down into asset-level scores from excellent to low.

Step 3

Take action

Take action to get a higher score by updating asset meta data or connections.

Step 4

Your winning score

Achieving an excellent score means no further action is required and you are getting the most accurate emissions estimates.

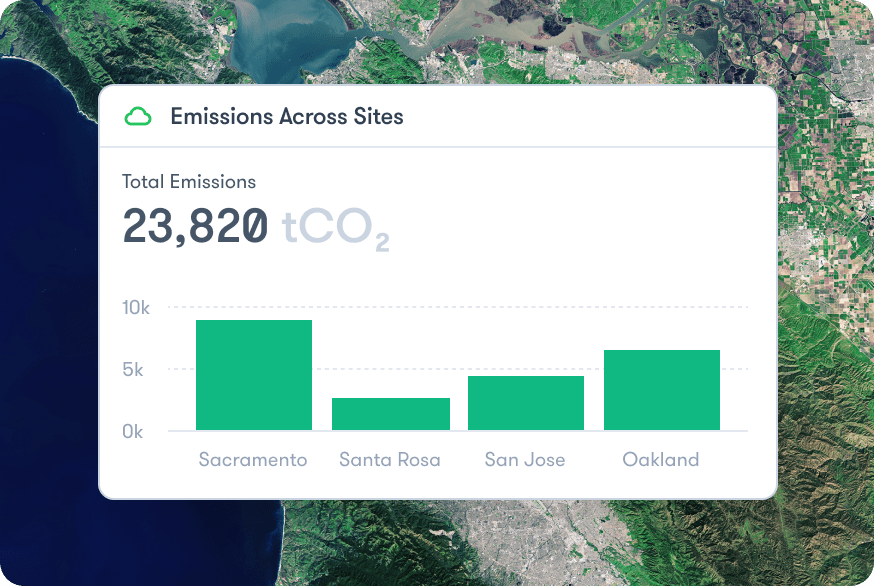

Track your emissions wherever your equipment operates

Surface key insights with fuel and emissions tracking spanning your entire construction fleet—across job sites, depots, or areas you define—all to win contracts and keep projects on track.

Stay compliant

Meet regulations,

avoid costly penalties

Accurately measure carbon outputs to maintain compliance, safeguard your reputation, and free your projects from fines or potentially costly disruptions.

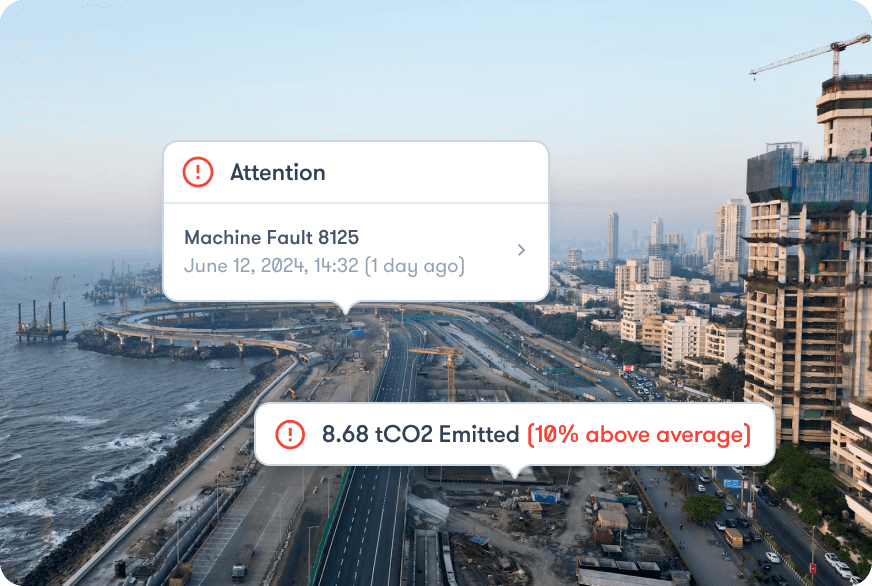

Real-time visibility

Spot issues early,

control equipment usage

Gain insight into each machine’s performance across multiple sites, quickly troubleshoot problems, and schedule maintenance before downtime occurs.

Insight-fueled growth

Turn emissions data

into strategic opportunities

Harness complete fleet-wide emissions tracking for data-driven decisions—like downsizing or adopting cleaner machines—cultivating long-term sustainability, competitive advantage, and lasting success.

Efficiency unleashed

Reduce fuel consumption and costs

25%

Reduction in diesel consumption by analyzing real-time data across mixed-brand fleets and machine-level insights paved way for targeted fuel-saving measures.

Wins bids to stay in the game

65%

Of contractors cite data-backed sustainability efforts as a key factor in awarding bids, underscoring the market advantage of real-time emissions insights.

Save across every jobsite

15%

Of sites using automated telematics and analytics saw average fuel savings of 15% and a corresponding decrease in CO₂ emissions after implementing dashboards.

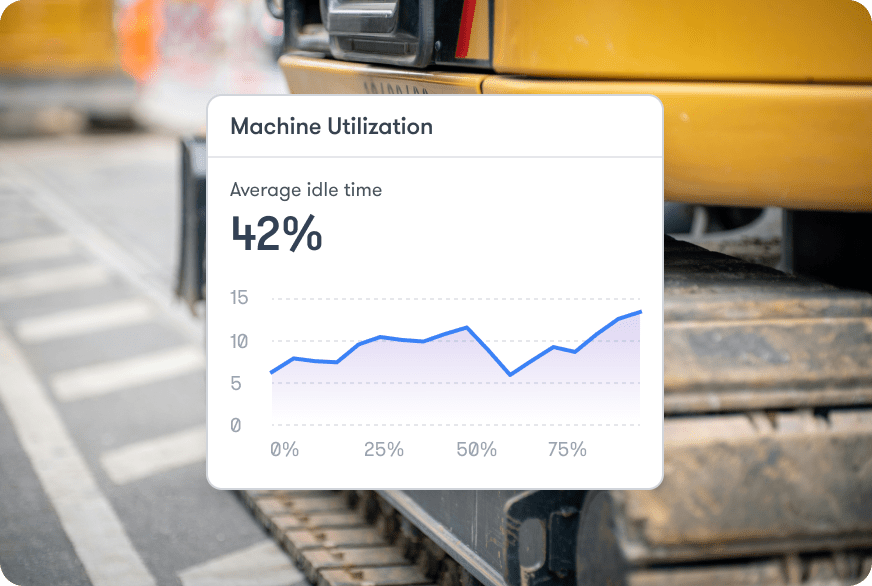

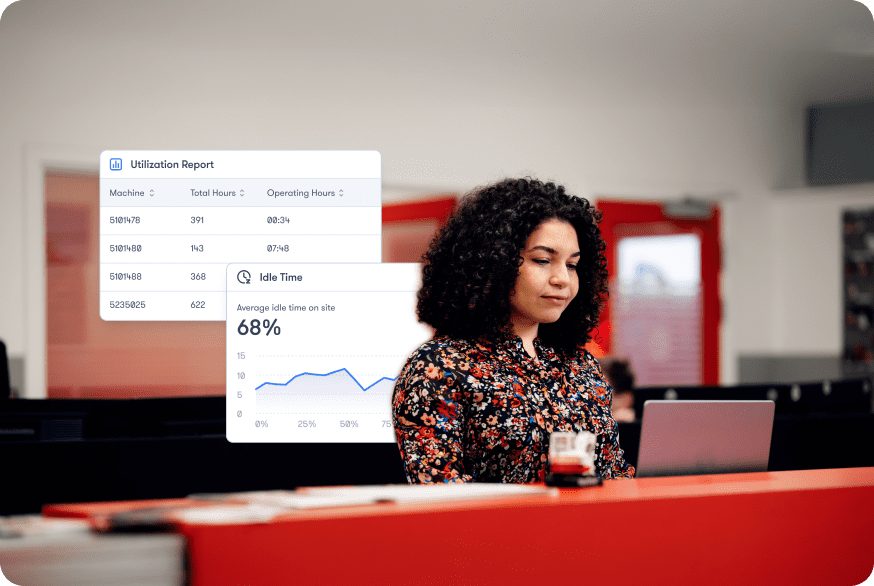

Every minute of idling

is a missed chance

With utilization reports, surface key insights to optimize machine usage driving performance and productivity every day.

Actionable usage

Uncover daily machine performance

Compare operating hours against expected targets to reveal underutilized machines, reduce downtime, and maximize efficiency across every jobsite.

Idle insights

Expose non-productive machine hours

Track idling to cut wasted fuel and emissions, ensuring more precise project timelines, lower costs, and boosted sustainability.

Emissions impact

Optimize usage for lower carbon footprint

Combine usage and idle data with emissions reporting to measure real impact, meet regulations, and strengthen your brand’s sustainability leadership.

Join the best in business

Trusted by leading OEMs, rental companies, contractors, and partners to unlock the full value of their fleets and equipment.

Joel Särkkä

CIO, Renta

“Digitization has been an integral part of being able to scale the business. It forces us to think outside of the box and come up with new solutions. But we always keep in mind that the solutions we create should serve the people using them.”

Roger Rotés

Product Manager, AUSA

"We launched the AUSAnow solution together with Trackunit during 2021,” Roger Rotés, Product Manager at AUSA says. “The partnership between AUSA and Trackunit exemplifies the power of collaboration in driving operational excellence and customer satisfaction."

Jenna Reed

Director, Sunbelt Rentals

"Through our partnership with Trackunit, we are enabling a better end-to-end experience for our customers through data. Having robust equipment data from Trackunit Manager, which pulls in critical information from our IoT devices, is critical to our operations."

Request a demo

Discover all your

possibilities

Experience a world of opportunity by plugging into construction.

Trackunit® Manager

Work smarter with full fleet intelligence

Say goodbye to fragmented views by using the #1 chosen interface in the industry to connect, collect, and present all your equipment insights in a single platform

Dig deeper into

sustainability

Keep up to date on news surrounding the platform’s capabilities,

development, and the technology behind it.